Magnetostrictive/resonator series connection composite resonant magnetic sensor

A magnetostrictive and magnetic sensor technology, applied in the field of magnetic sensors, can solve the problem of limited frequency variation, such as the magnetostrictive coefficient, and achieve the effects of eliminating signal processing circuits, strong anti-noise interference ability, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

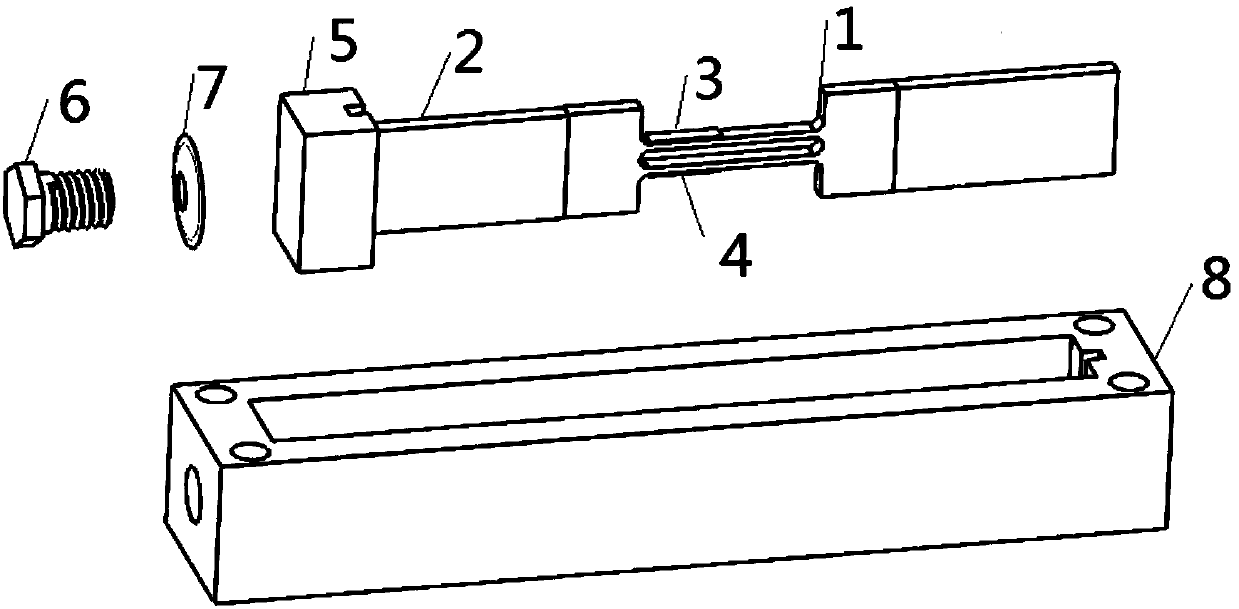

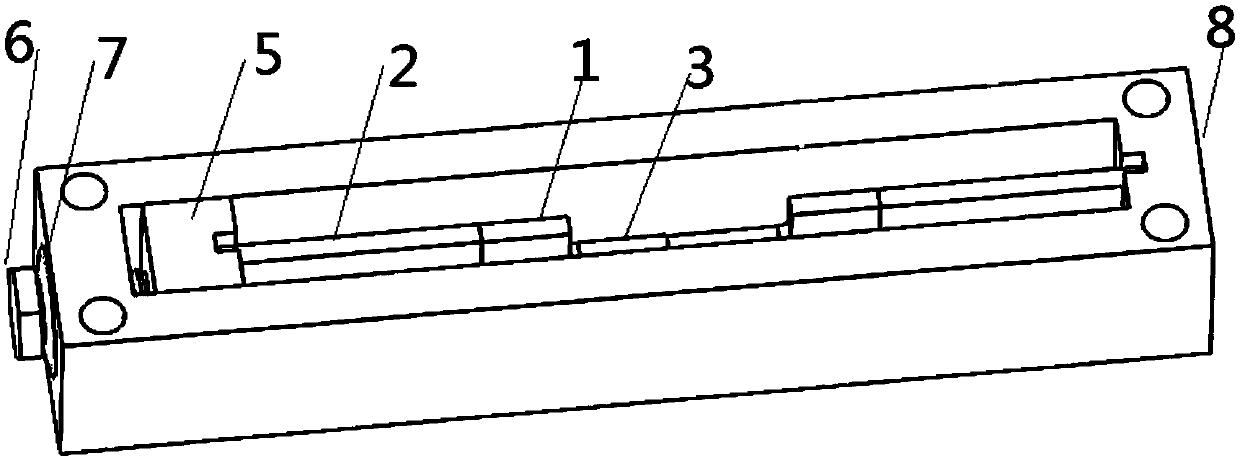

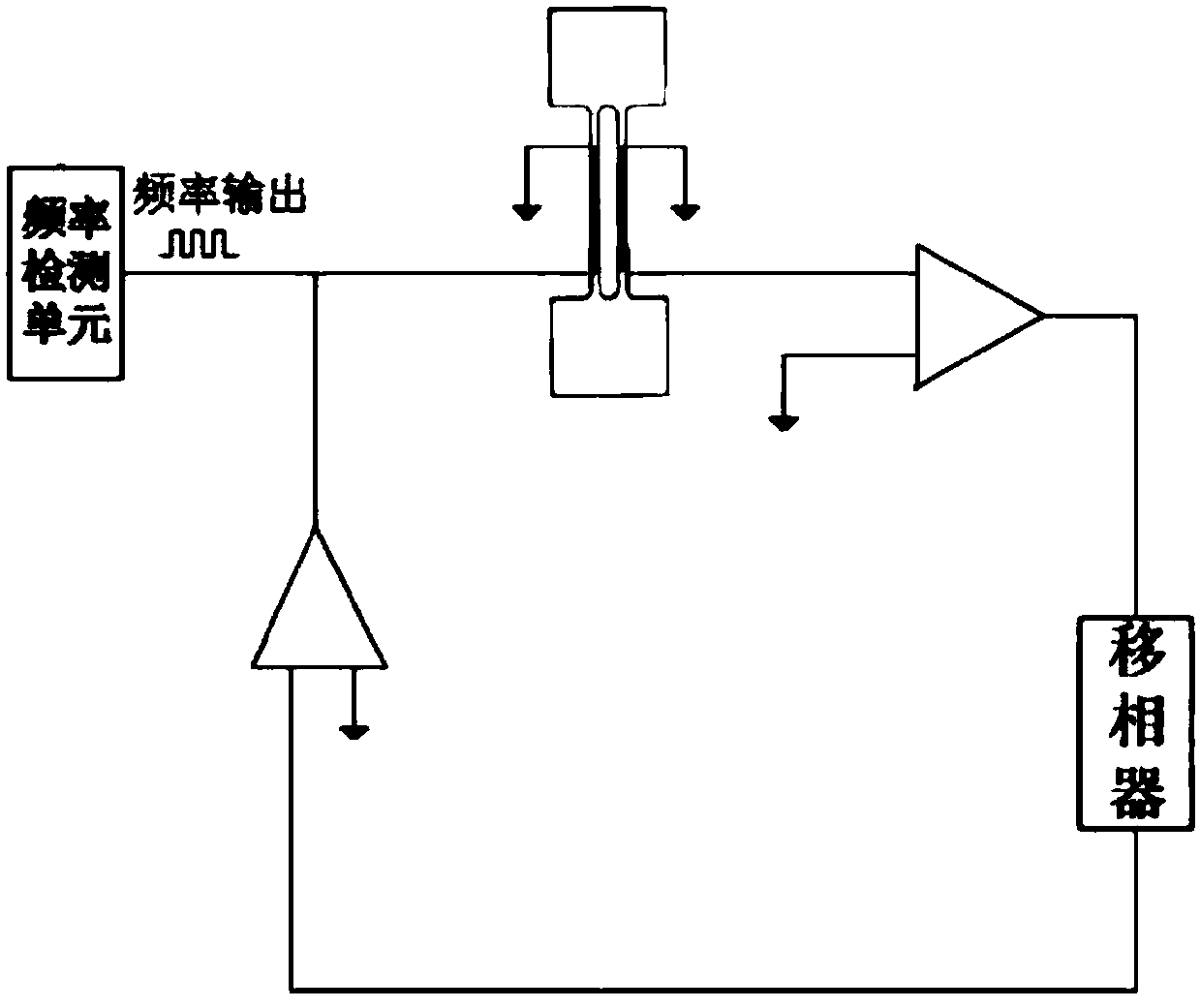

[0032] combine figure 1 and figure 2 , in this embodiment, a resonant magnetic sensor with a digital frequency output magnetostrictive / resonator series composite, including two magnetostrictive plates 2, a metal tuning fork resonator 1, a fixed support structure, an oscillating circuit, and a frequency detection unit, wherein the two ends of the metal tuning fork resonator 1 are respectively connected to one end of the corresponding magnetostrictive sheet 2; The other end of the stretchable sheet is snapped into the groove of the spacer 5; there is a threaded hole on one side of the packaging shell 8, and the spacer 5 is fastened to the threaded hole by the fastening screw 6 and the disc spring 7, thereby resonating the metal tuning fork The device 1 and the magnetostrictive sheet 2 are fixed in the groove of the fixed support structure through the pad 5; the root of the vibrating beam of the metal tuning fork resonator 1 is bonded with a piezoelectric drive unit 3 and a pie...

Embodiment 2

[0037] combine Figure 4 and Figure 5 As shown, the tuning fork resonator in this embodiment is a quartz tuning fork resonator 10, the fixed support structure is a base 11, grooves are provided at both ends of the base 11, and the other ends of the magnetostrictive sheet 2 are respectively fixed in the grooves , and respectively fix a pressing piece 9 on the port where the two magnetostrictive pieces 2 are located in the groove. Adhesive, welding and other methods are used to closely combine the pressing piece 9 with the grooves at both ends of the base 11, so that the end of the magnetostrictive sheet inserted into the groove is fixed.

[0038] The quartz tuning fork resonator 11 is a double-beam quartz tuning fork fixed at both ends, and there are electrode pads at both ends of the tuning fork for connecting to an external oscillating circuit. The quartz tuning fork resonator 11 works in the bending vibration mode, and the vibration directions of the two beams are symmetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com