Covalent organic framework/graphene compound organic material, as well as preparation method and application thereof in lithium/sodium ionic battery anode materials

A covalent organic framework, graphene composite technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as hindering lithium/sodium ion conduction, poor cycle performance, poor rate performance, etc., to achieve large-scale benefits. The effect of industrial production, low solubility, high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

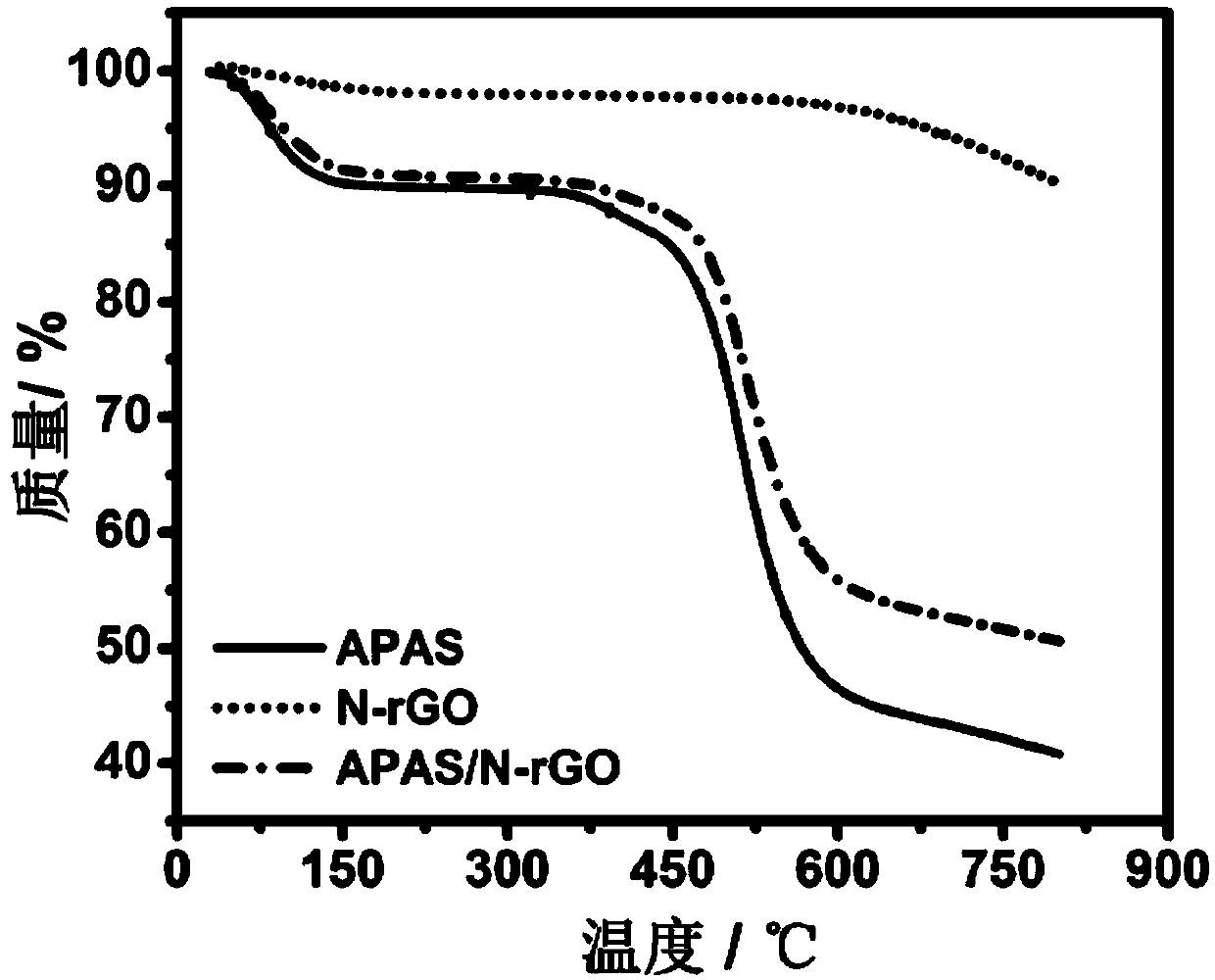

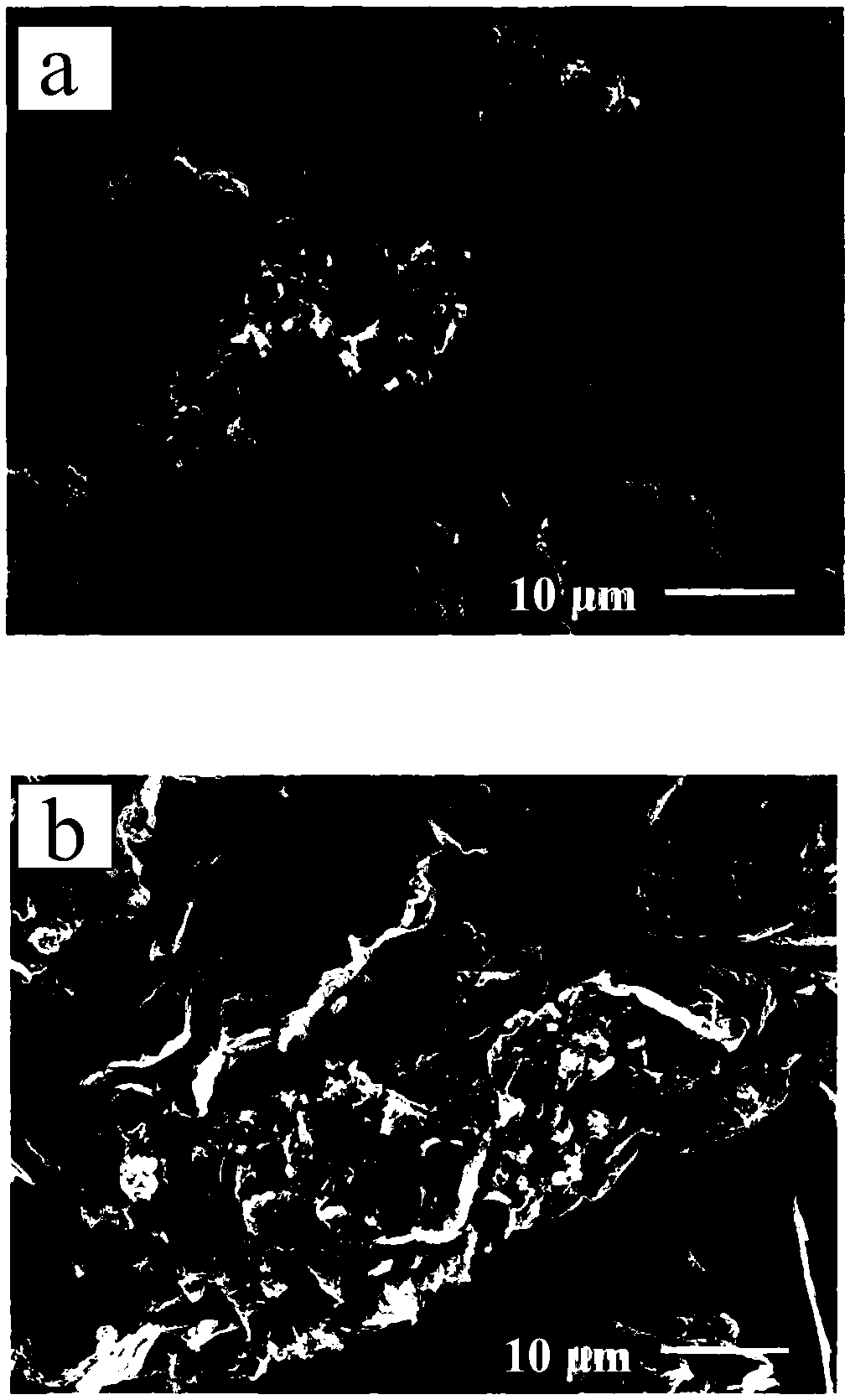

[0046] (1) The graphene oxide (GO) solution was prepared by the improved Hummers method, and the graphene oxide solution was freeze-dried and calcined at 750°C for 30 minutes under ammonia gas to obtain nitrogen-doped reduced graphene oxide (N-rGO) flakes .

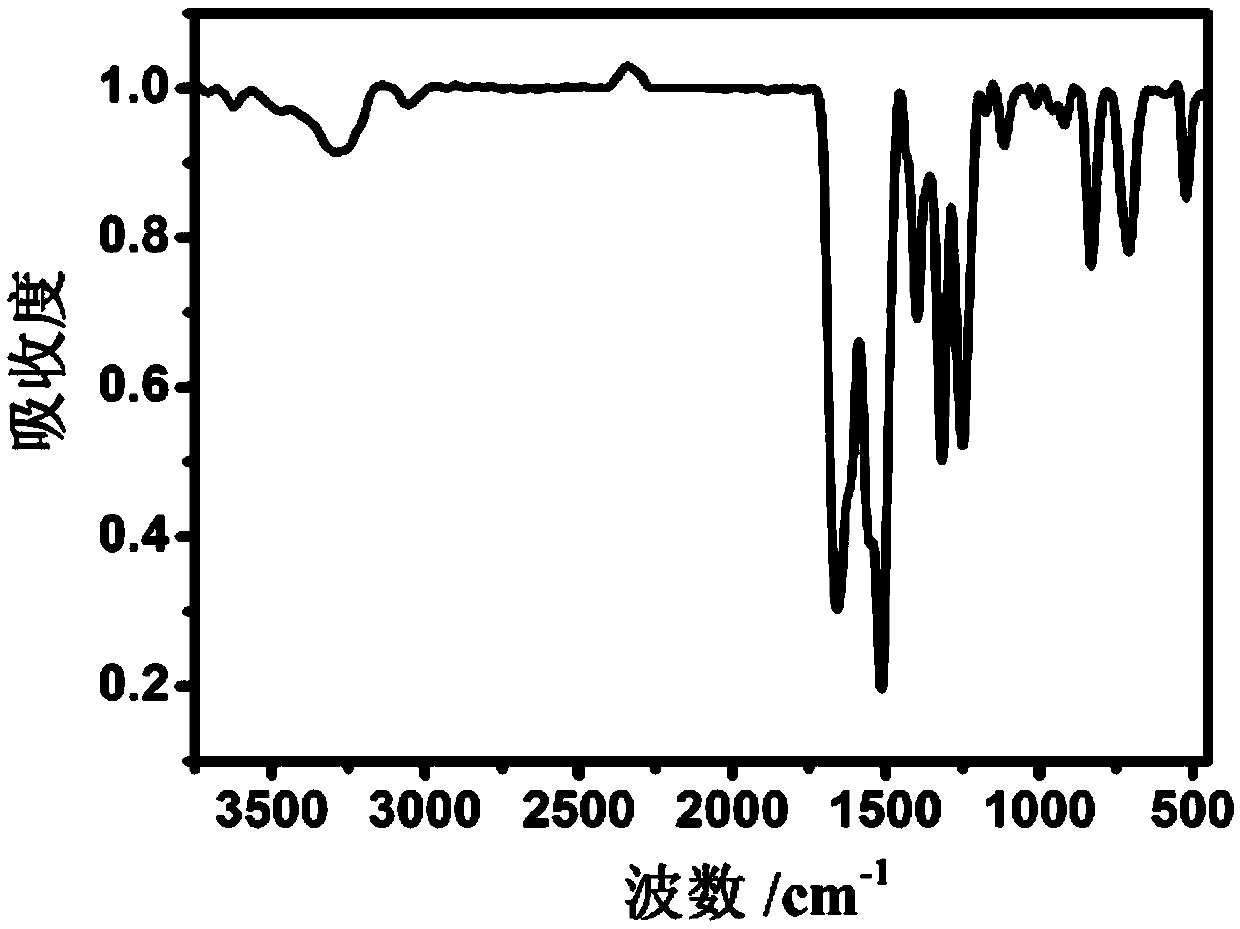

[0047] (2) Add 2 molar parts of 1,3,5-benzenetricarboxylic acid chloride and 3 molar parts of p-phenylenediamine in a molar ratio of 1:1.5 into the ball mill tank, and then add 100 parts by mass of the N- The rGO flakes were ball milled at a high speed for 15 minutes, and then 15 volume parts of 5% NaOH solution was added to continue ball milling for 10 minutes. The obtained product was alternately washed three times with water and ethanol, and finally freeze-dried to obtain the APAS / N-rGO organic composite material.

[0048] (3) APAS / N-rGO, Super P, and PVDF were mixed into a slurry in N-methylpyrrolidone solution at a mass ratio of 7:2:1, coated on a copper foil, and dried in vacuum at 80°C to obtain a negative electro...

Embodiment 2

[0054] (1) The graphene oxide (GO) solution was prepared by the improved Hummers method, and the graphene oxide solution was freeze-dried and then calcined at 700°C for 30 minutes under ammonia gas to obtain nitrogen-doped reduced graphene oxide (N-rGO) flakes .

[0055] (2) Add 2 molar parts of 1,3,5-benzenetricarboxylic acid chloride and 3 molar parts of p-phenylenediamine in a molar ratio of 1:1.5 into the ball mill tank, and then add 100 parts by mass of the N- The rGO flakes were ball milled at a high speed for 15 minutes, and then 15 volume parts of 5% NaOH solution was added to continue ball milling for 10 minutes. The obtained product was alternately washed three times with water and ethanol, and finally freeze-dried to obtain the APAS / N-rGO organic composite material.

[0056] (3) APAS / N-rGO, Super P, and PVDF were mixed into a slurry in N-methylpyrrolidone solution at a mass ratio of 7:2:1, coated on a copper foil, and dried in vacuum at 80°C to obtain a negative el...

Embodiment 3

[0059] (1) The graphene oxide (GO) solution was prepared by the modified Hummers method, and the graphene oxide solution was freeze-dried and then calcined at 800°C for 30 minutes under ammonia gas to obtain nitrogen-doped reduced graphene oxide (N-rGO) flakes .

[0060] (2) Add 2 molar parts of 1,3,5-benzenetricarboxylic acid chloride and 3 molar parts of p-phenylenediamine in a molar ratio of 1:1.5 into the ball mill tank, and then add 100 parts by mass of the N- The rGO flakes were ball milled at a high speed for 15 minutes, and then 15 volume parts of 5% NaOH solution was added to continue ball milling for 10 minutes. The obtained product was alternately washed three times with water and ethanol, and finally freeze-dried to obtain the APAS / N-rGO organic composite material.

[0061] (3) APAS / N-rGO, Super P, and PVDF were mixed into a slurry in N-methylpyrrolidone solution at a mass ratio of 7:2:1, coated on a copper foil, and dried in vacuum at 80°C to obtain a negative el...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap