Preparation method of sargassum fusiforme dietary fiber

A technology for dietary fiber and hijiki, which is applied in the field of preparation of hijiki dietary fiber, achieves the effects of protecting tissue structure and physiological function, increasing full penetration and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

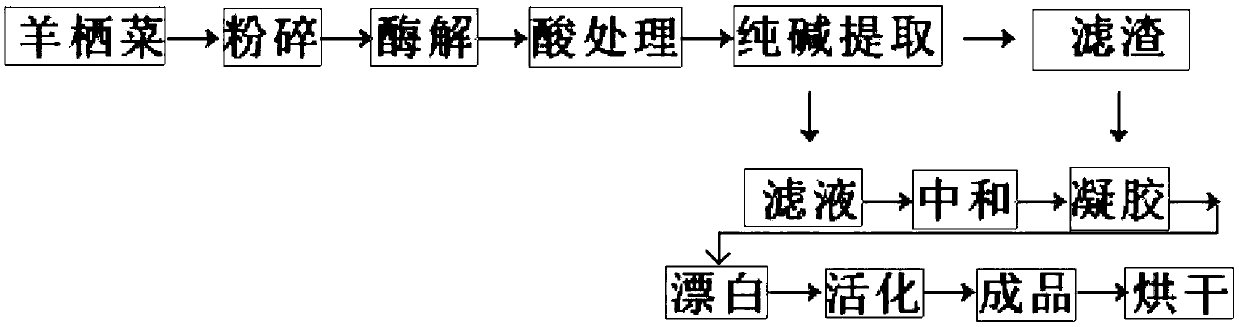

Method used

Image

Examples

Embodiment 1

[0038] The preparation method of embodiment 1, hijiki dietary fiber may further comprise the steps:

[0039] (1), fresh hijiki is dried to constant weight, pulverized, crosses 60 mesh sieves;

[0040] (2) Enzymolysis: by adding 1 mol / L dilute hydrochloric acid to adjust the pH to 4-5 and a temperature of 48°C, add a compound enzyme accounting for 0.1% of the weight of Hijiki after crushing, and perform enzymolysis for 0.5h;

[0041] The compound enzyme is composed of 20FBG / g compound plant hydrolase and 5000u / g papain; the mass ratio of compound plant hydrolase and papain is 1:30;

[0042] (3) Acid hydrolysis: add 0.1mol / L HCl solution 10 times the mass of Hijiki after enzymolysis, soak for 1 hour, then wash until neutral and squeeze out the water; repeat the above process once;

[0043] (4) Alkaline hydrolysis: 10g / LNa 25 times the mass of hijiki after acid hydrolysis at a temperature of 75°C 2 CO 3 The solution was digested for 2h;

[0044] (5), after alkaline hydrolysis...

Embodiment 2

[0052] The preparation method of embodiment 2, hijiki dietary fiber may further comprise the steps:

[0053](1), the fresh Hijiki is dried, pulverized, and crossed a 70-mesh sieve;

[0054] (2) Enzymolysis: by adding 1 mol / L dilute hydrochloric acid to adjust the pH at 4.5 and a temperature of 49°C, add a compound enzyme accounting for 0.1% of the weight of Hijiki after crushing, and perform enzymolysis for 1 hour;

[0055] The compound enzyme is composed of 20FBG / g compound plant hydrolase and 5000u / g papain; the mass ratio of compound plant hydrolase and papain is 1:35;

[0056] (3) Acid hydrolysis: add 0.1mol / L HCl solution of 10 times the mass to the enzymatically hydrolyzed Hijiki, soak for 1 hour, then wash until neutral and squeeze out the water; repeat the above process once;

[0057] (4) Alkaline hydrolysis: use 10g / LNa of 25 times the mass of hijiki after acid hydrolysis at a temperature of 77°C 2 CO 3 The solution was digested for 2h;

[0058] (5), after alkalin...

Embodiment 3

[0066] The preparation method of embodiment 3, hijiki dietary fiber may further comprise the steps:

[0067] (1), fresh Hijiki is dried to constant weight, pulverized, and crossed an 80-mesh sieve;

[0068] (2) Enzymolysis: by adding 1 mol / L dilute hydrochloric acid to adjust the pH to 5 and the temperature at 50°C, add a compound enzyme accounting for 0.1% of the weight of Hijiki after crushing, and perform enzymolysis for 1.5 hours;

[0069] The compound enzyme is composed of 20FBG / g compound plant hydrolase and 5000u / g papain; the mass ratio of compound plant hydrolase and papain is 1:40;

[0070] (3) Acid hydrolysis: add 0.1mol / L HCl solution of 10 times the mass to the enzymatically hydrolyzed Hijiki, soak for 1 hour, then wash until neutral and squeeze out the water; repeat the above process once;

[0071] (4) Alkaline hydrolysis: 10g / LNa 25 times the mass of hijiki after acid hydrolysis at a temperature of 80°C 2 CO 3 The solution was digested for 2h;

[0072] (5), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com