Preparation method and application of modified ZIF-8/GO composite membrane

A technology of ZIF-8 and composite membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve copper pollution accidents, copper health problems and other problems, and achieve the effect of improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

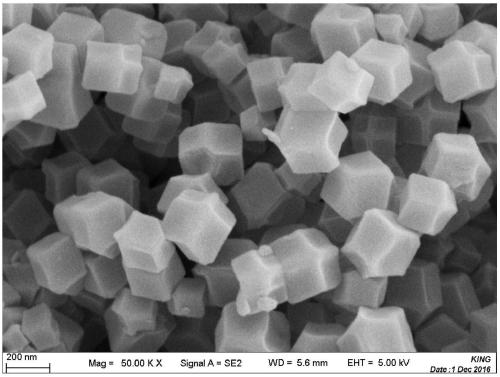

[0029] (1) Take 0.539g Zn(NO 3 ) 2 and 3.234g of 2-Im were respectively dissolved in 40mL of methanol, and ultrasonically stirred for 30min. It was centrifuged for 15 min, washed with methanol three times and filtered, and the obtained powder was vacuum-dried in an oven at 85°C.

[0030] (2) Dissolve 0.2 g of the product obtained in (1) in 30 mL of methanol, and add 0.125 mL of APTES. The reaction was refluxed at 70°C for 5h. After cooling, the product was washed several times with dichloromethane and dried.

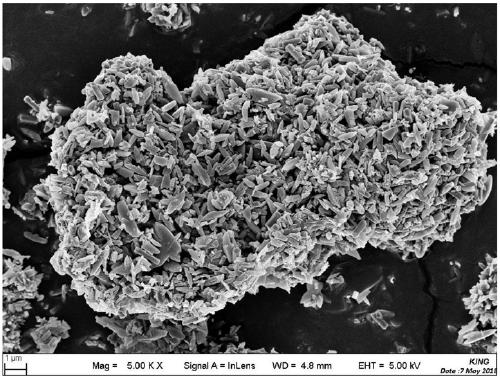

[0031] (3) Disperse 200 mg of graphene oxide in 200 mL of distilled water, add 1 mL of APTES, first ultrasonically stir for 30 min, and then mechanically stir for 24 h.

[0032] (4) The product of step (3) was washed with deionized water and centrifuged for 15 min to obtain sediment, and finally dried at 60 °C overnight.

[0033] (5) Dissolve 200 mg of the product in (2) in 30 mL of methanol, take 10 mg of the product in (4) and disperse it in 10 mL of ultrapure wat...

Embodiment 2

[0036] (1) Take 0.539g Zn(NO 3 ) 2 and 3.234g of 2-Im were respectively dissolved in 40mL of methanol, and ultrasonically stirred for 30min. It was centrifuged for 15 min, washed with methanol three times and filtered, and the obtained powder was vacuum-dried in an oven at 85°C.

[0037] (2) Dissolve 0.1 g of the product obtained in (1) in 20 mL of methanol, and add 0.1 mL of APTES. The reaction was refluxed at 70°C for 5h. After cooling, the product was washed several times with dichloromethane and dried.

[0038] (3) Disperse 150 mg of graphene oxide in 150 mL of distilled water, add 1.5 mL of APTES, first ultrasonically stir for 30 min, and then mechanically stir for 24 h.

[0039] (4) The product of step (3) was washed with deionized water and centrifuged for 15 min to obtain sediment, and finally dried at 60 °C overnight.

[0040] (5) Dissolve 100 mg of the product in (2) in 20 mL of methanol, take 5 mg of the product in (4) and disperse it in 10 mL of ultrapure wate...

Embodiment 3

[0043] (1) Take 0.539g Zn(NO 3 ) 2and 3.773g of 2-Im were respectively dissolved in 40mL of methanol, and ultrasonically stirred for 30min. It was centrifuged for 15 min, washed with methanol three times and filtered, and the obtained powder was vacuum-dried in an oven at 85°C.

[0044] (2) Dissolve 0.3 g of the product obtained in (1) in 40 mL of methanol, and add 0.2 mL of APTES. The reaction was refluxed at 70°C for 5h. After cooling, the product was washed several times with dichloromethane and dried.

[0045] (3) Disperse 300 mg of graphene oxide in 200 mL of distilled water, add 1.5 mL of APTES, first ultrasonically stir for 30 min, and then mechanically stir for 24 h.

[0046] (4) The product of step (3) was washed with deionized water and centrifuged for 15 min to obtain sediment, and finally dried at 60 °C overnight.

[0047] (5) Dissolve 200 mg of the product in (2) in 20 mL of methanol, take 15 mg of the product in (4) and disperse it in 20 mL of ultrapure wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com