Reinforced component, additive processing device and processing method with online strengthening effect

A technology of components and components, which is applied in the field of additive processing devices with online strengthening effect, can solve the problem of insufficient area strengthening, and achieve the effects of gentle elastic curve, stable work and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings.

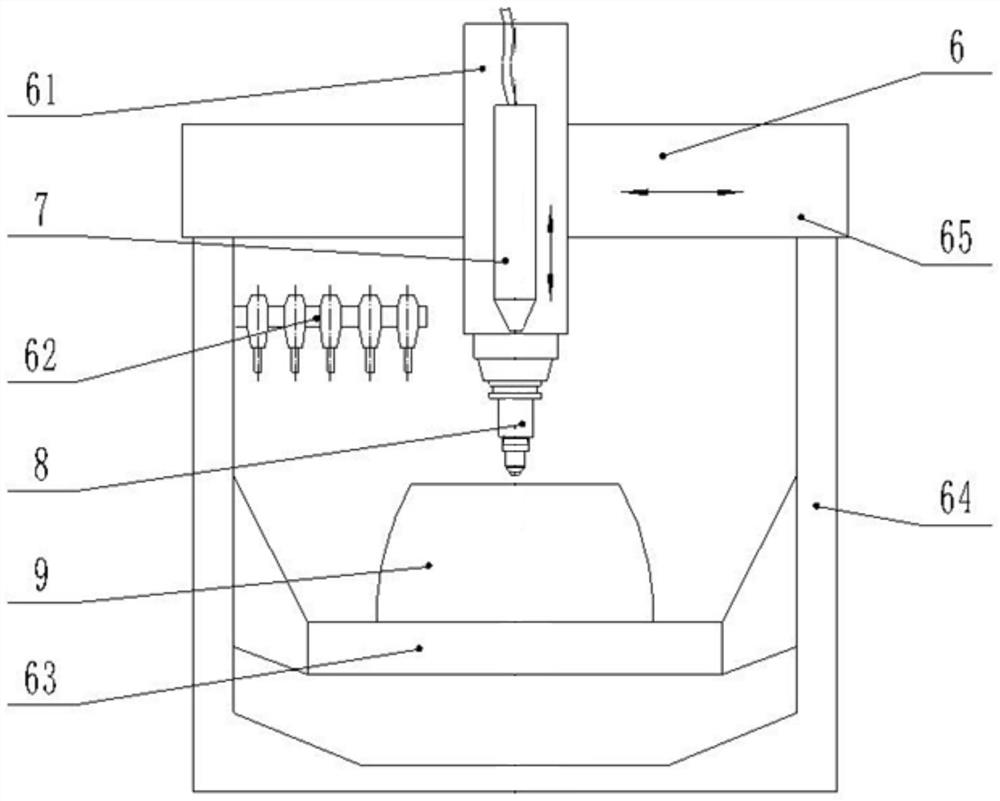

[0050] Such as figure 2As shown, the present invention has an additive processing device with an online strengthening effect, including a machine tool 6 and a printing head. The machine tool 6 includes a spindle box 61 and a worktable 63. The workbench 63 is located below the spindle box 61. The lower end of the spindle box 61 has a spindle interface.

[0051] In the embodiment of the present invention, the bed 64 of the machine tool 6 adopts a currently common five-axis machining center structure, the spindle box 61 can realize the movement in the three directions of X, Y, and Z, and the up and down movement in the Z direction is the spindle box. 61 is realized through the connection of the wire gauge, the lead screw and the slide plate; the left and right movement in the X direction is realized through the connection between the slide plate and the ram 65; at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com