Technology for treating printing and dyeing wastewater

A technology for printing and dyeing wastewater and treatment process, applied in water/sewage treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of increased decolorization cost, deep water output, unfavorable discharge or production reuse, etc. Achieving good purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

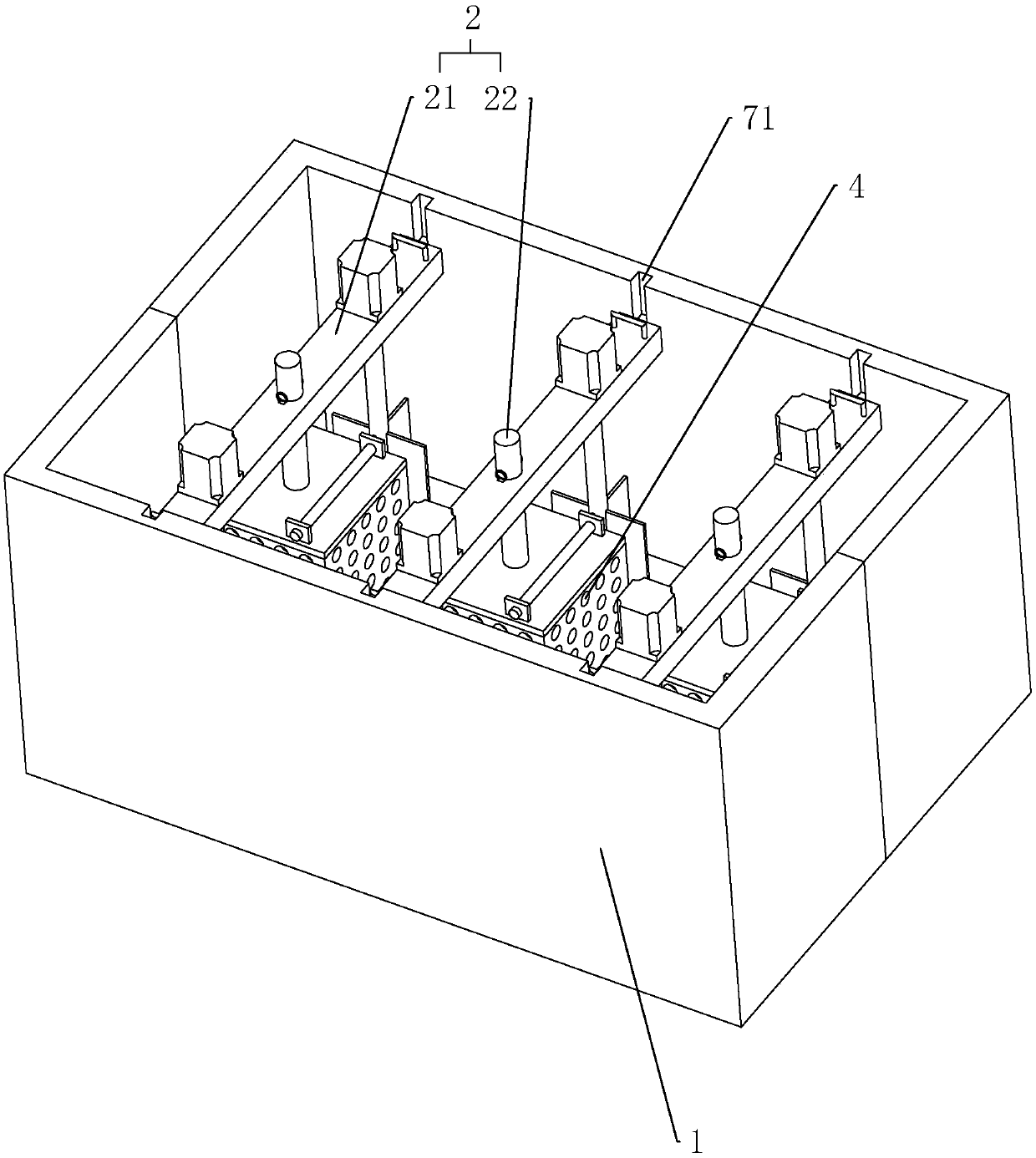

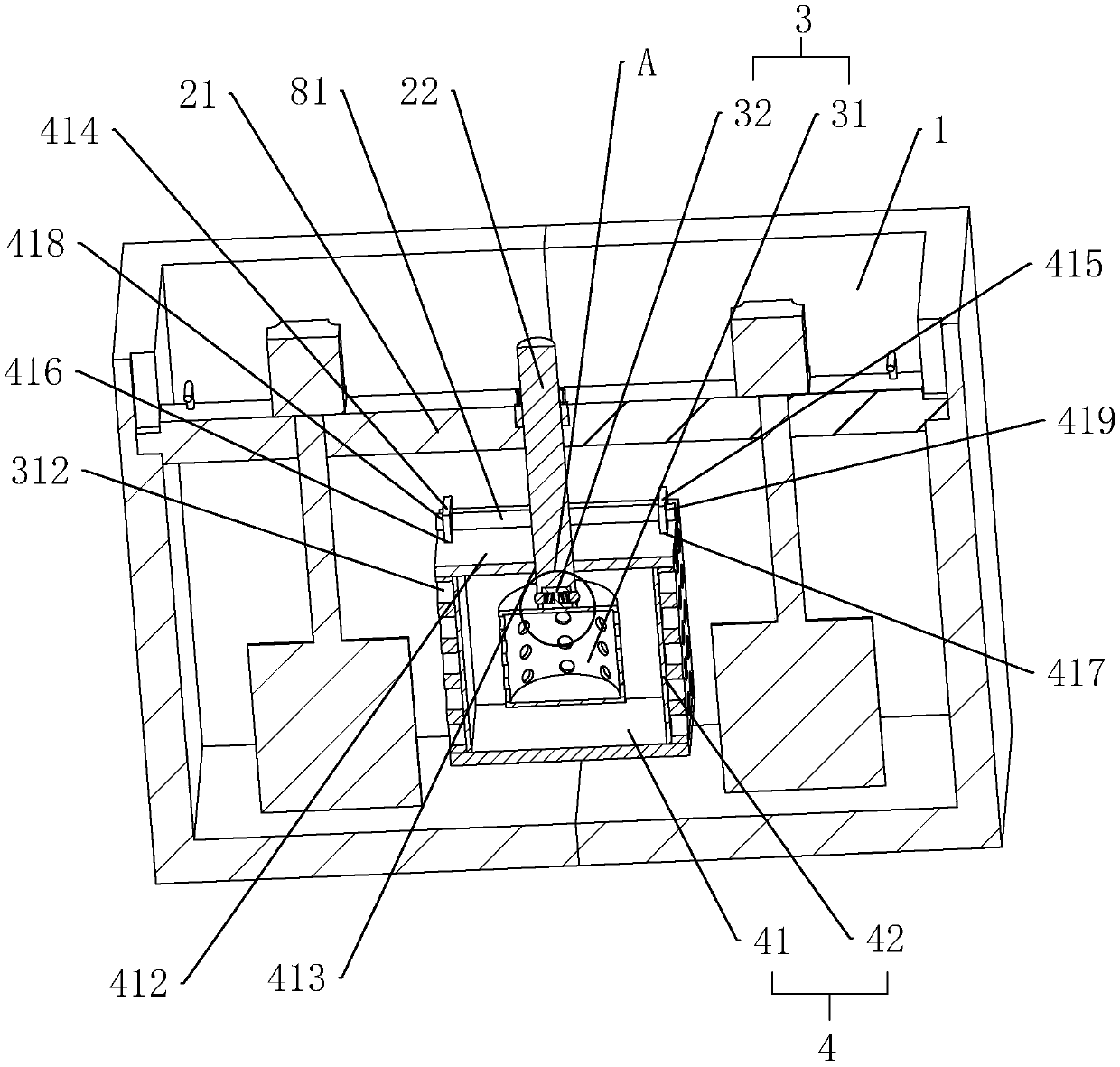

Image

Examples

preparation example Construction

[0054] (4) Preparation of adsorbent: a. 10 parts of eucalyptus bark, 5 parts of rice husk, 30 parts of bamboo, 3 parts of coconut shell, 10 parts of cassava skin and 5 parts by weight of peanut shell are rolled into powder;

[0055] b. Then compound rice husks, cassava skins, peanut shells, coconut shells, bamboo, and eucalyptus skins into spherical porous particles from the inside out.

[0056] Wastewater treatment: S1: Discharge the printing and dyeing wastewater into the regulating tank to adjust the flow and quality of the wastewater, and add industrial sulfuric acid to the regulating tank to adjust the pH of the wastewater to 6;

[0057] S2: Pass the wastewater in the regulating tank into the settling tank, and add a settling agent into the settling tank for settling;

[0058] S3: Simple filtration of the settled wastewater in the settling tank;

[0059] S4: Mix the decolorizing agent and the microbial growth promoter into the decolorizing tank, and then introduce the fi...

Embodiment 1

[0081] The difference between embodiment 10-21 and embodiment 1 is: the parts by weight of each component in the described decolorizing agent is counted as following table:

[0082]

[0083] The difference between embodiment 22-25 and embodiment 1 is: the weight percentage of each component in the described microbial growth promoter is calculated as the following table:

[0084]

[0085] The difference between Examples 26-29 and Example 1 is that the parts by weight of each component in the adsorbent are as follows:

[0086]

[0087] The difference between Embodiment 30-33 and Embodiment 1 is that: the value of the pH adjusted in the adjustment pool is as follows:

[0088] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com