Oil removal abrasive block for rail transit

A technology of rail transit and oil research, applied in other chemical processes, chemical instruments and methods, etc., can solve the problem of slow recovery of friction coefficient, and achieve the effect of eliminating slippage, avoiding the reduction of bonding strength, and improving the effect of oil removal and antiskid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

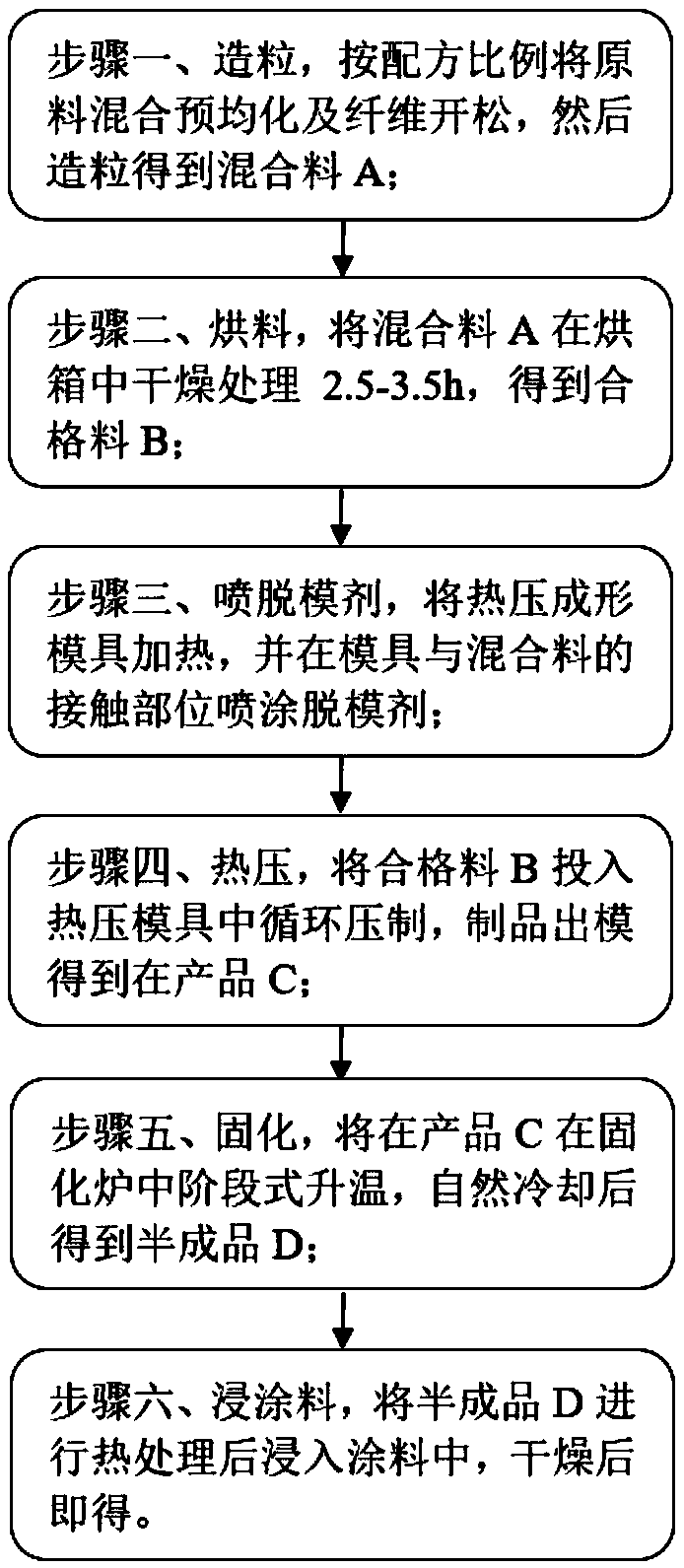

Method used

Image

Examples

Embodiment 1

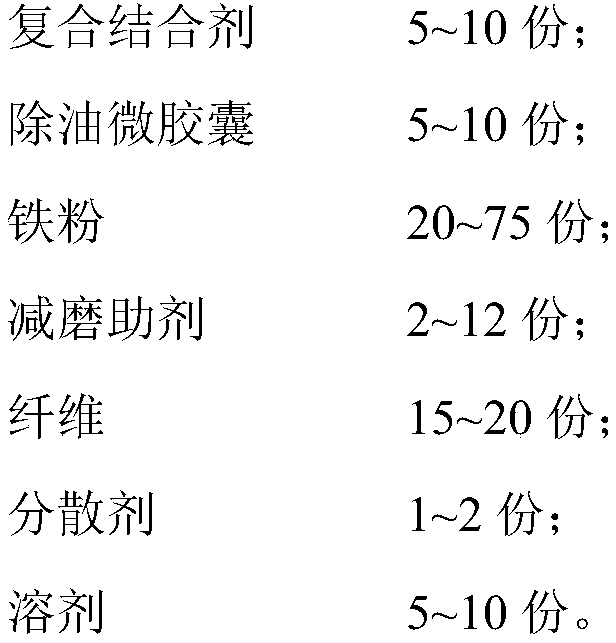

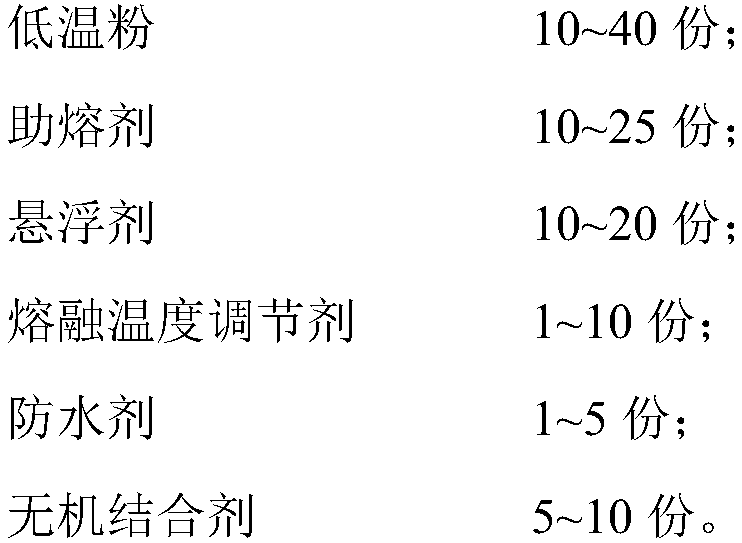

[0039] combine figure 1 , a kind of degreasing grinder for rail transit of the present embodiment comprises the following raw materials in parts by weight:

[0040] 10 parts of compound binder;

[0041] The composite binder includes an inorganic binder and an organic binder, and the addition ratio of the inorganic binder to the composite binder is 1 / 5, wherein the composite binder includes the following raw materials by weight: 2 parts by weight of the inorganic binder and The organic binding agent of 8 weight parts;

[0042]

[0043]

[0044]The organic binder described in this embodiment is organosilicon modified phenolic resin; the inorganic binder is boron glass powder; the anti-friction aid is phosphorus flake graphite; the fiber is steel fiber and copper-plated fiber; The iron powder is foam iron powder with a particle size of 100-200 meshes to increase the friction coefficient; the dispersant is ethylene glycol; the solvent is furfural liquid.

[0045] In this ...

Embodiment 2

[0065] A kind of degreasing grinder for rail transit of the present embodiment, its composition is basically the same as that of Embodiment 1, and its difference is:

[0066] A kind of degreasing grinding wheel for rail transit of the present embodiment comprises the following raw materials in parts by weight:

[0067] 8 parts of compound binder;

[0068] The composite binder includes an inorganic binder and an organic binder, and the addition ratio of the inorganic binder to the composite binder is 1 / 5, wherein the composite binder includes the following raw materials by weight: 1.6 parts by weight of the inorganic binder and The organic binder of 6.4 parts by weight;

[0069]

[0070] The organic binding agent described in the present embodiment is the mixture of organosilicon modified phenolic resin and boron modified aldehyde resin; Described inorganic binding agent is borax; Described anti-friction aid is the mixture of phosphorus flake graphite and carbon black; The...

Embodiment 3

[0085]A kind of degreasing grinder for rail transit of the present embodiment, its composition is basically the same as that of Embodiment 1, and its difference is:

[0086] A kind of degreasing grinding wheel for rail transit of the present embodiment comprises the following raw materials in parts by weight:

[0087] 7.5 parts of composite binder;

[0088] The composite binder includes an inorganic binder and an organic binder, and the addition ratio of the inorganic binder to the composite binder is 3 / 10, wherein the composite binder includes the following raw materials by weight: 2.25 parts by weight of the inorganic binder and The organic binder of 5.25 parts by weight;

[0089]

[0090] The organic binder described in this embodiment is boron-modified aldehyde resin; the inorganic binder is boron glass powder; the anti-friction additive is phosphorus flake graphite; the fiber is steel fiber and copper-plated fiber; The iron powder is foam iron powder with a particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com