Crystallization method for improving crystal habit of ethyl vanillin by adding polyvinylpyrrolidone

A technology of polyvinylpyrrolidone and ethyl vanillin, which is applied in the separation/purification of carbonyl compounds, organic chemistry, etc., and can solve the problems that there is no patent for the recrystallization and refining process of ethyl vanillin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

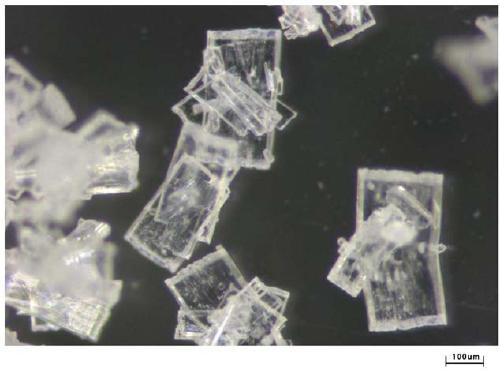

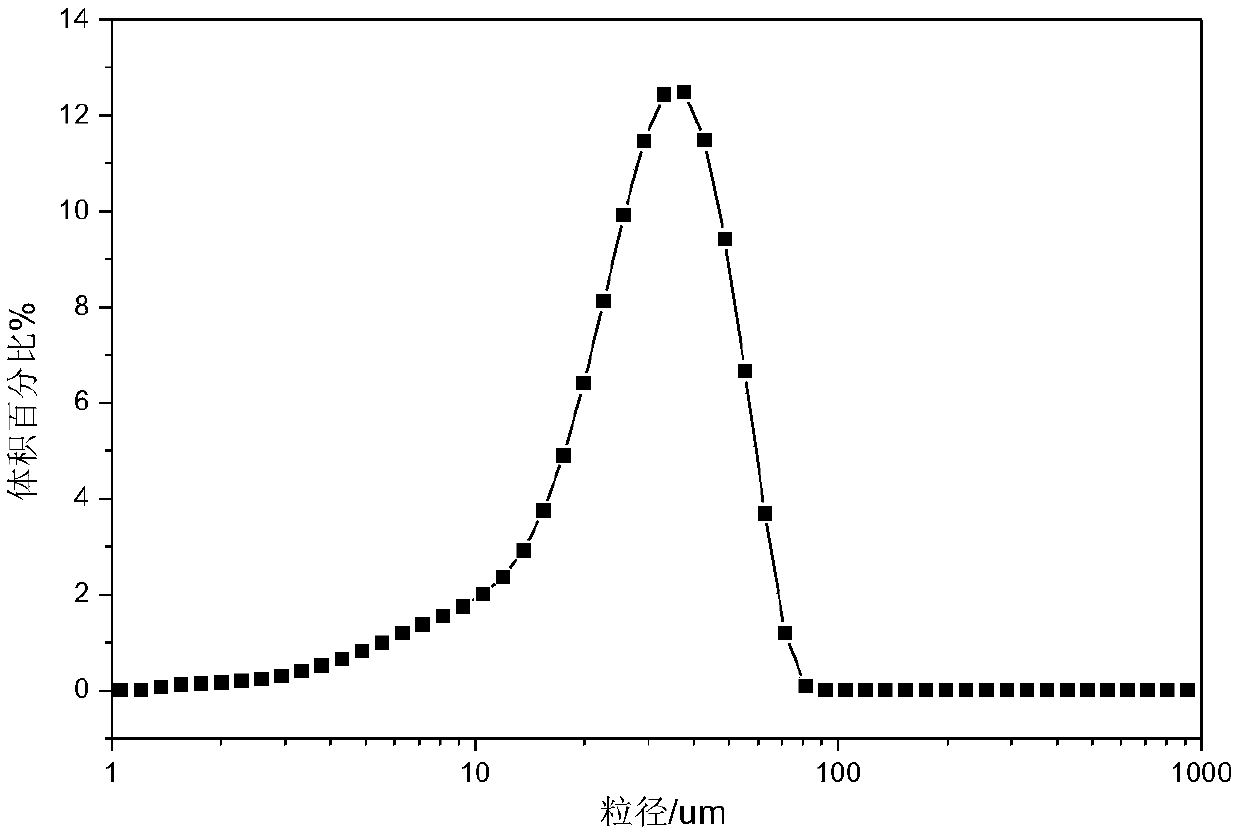

[0027] Add 65g of distilled water to 35g of absolute ethanol, then add 15g of ethyl vanillin and 0.05g of polyvinylpyrrolidone K60, heat up to 50°C under stirring, and cool down to 21°C at a rate of 12°C / h after all solids are dissolved . Subsequently, 2% ethyl vanillin by mass of ethyl vanillin was added as a seed crystal, and the crystal was grown for 30 minutes. After the crystal growth, the temperature was lowered to 0°C at a rate of 12°C / h. The product was obtained after filtration and drying. The product is a thick flaky colorless transparent crystal with a crystal habit like figure 2 As shown, the aspect ratio is 0.22, the tap density is 0.433g / ml, the angle of repose is 47°, and the particle size distribution is as follows Figure 4 As shown, the main particle size d(0.5) is 275 μm.

Embodiment 2

[0029] Add 55g of distilled water to 45g of absolute ethanol, then add 22.5g of ethyl vanillin and 0.50g of polyvinylpyrrolidone K60, heat up to 50°C under stirring, and cool down to 21.5°C at a rate of 12°C / h after all solids are dissolved. ℃. Subsequently, ethyl vanillin with 1% mass of ethyl vanillin was added as a seed crystal, and the crystal was grown for 20 minutes. After the crystal growth, the temperature was lowered to 5°C at a rate of 12°C / h. The product was obtained after filtration and drying. Its aspect ratio is 0.12, the tap density of the product is 0.469g / ml, the angle of repose is 37°, and the main particle size d(0.5) is 508μm.

Embodiment 3

[0031] Add 70g of distilled water to 30g of absolute ethanol, then add 10g of ethyl vanillin and 0.1g of polyvinylpyrrolidone K90, heat up to 35°C under stirring, and cool down to 15°C at a rate of 2.5°C / h after all solids are dissolved . Subsequently, 0.01% ethyl vanillin by mass of ethyl vanillin was added as a seed crystal, and the crystal was grown for 40 minutes. After the crystal growth, the temperature was lowered to 0°C at a rate of 2.5°C / h. The product was obtained after filtration and drying. Its aspect ratio is 0.27, the tap density of the product is 0.451g / ml, and the angle of repose is 45°. The main particle size d(0.5) is 382 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Angle of repose | aaaaa | aaaaa |

| Master granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com