High hardness, high wear resistance, anti-fingerprint UV curing coating

A light-curing coating, high wear-resistant technology, applied in the field of coatings, can solve the problems of reduced anti-fouling effect of the coating, decreased light transmittance of the coating, loss of light of the coating, etc., to improve the anti-fingerprint contamination characteristics, reduce Internal stress concentration, the effect of ensuring transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

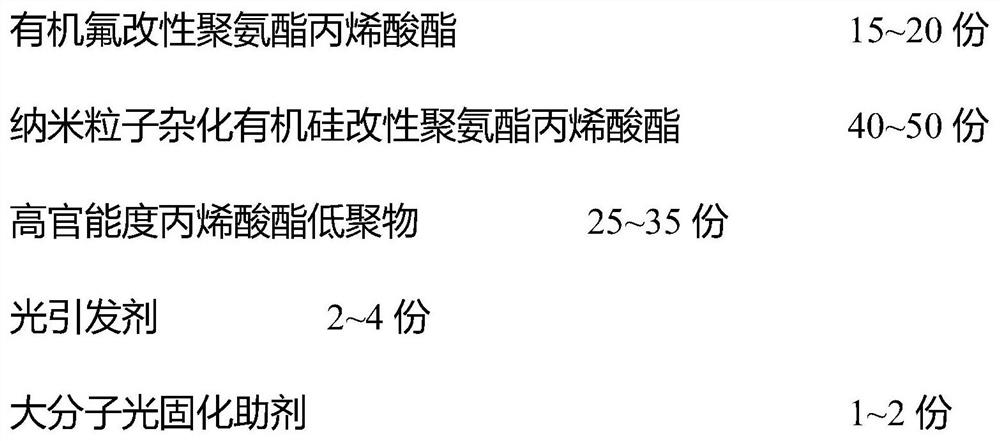

[0023] This embodiment relates to a high-hardness, high-abrasion and anti-fingerprint UV-curable coating. Concretely comprise each component of mass parts as shown below:

[0024]

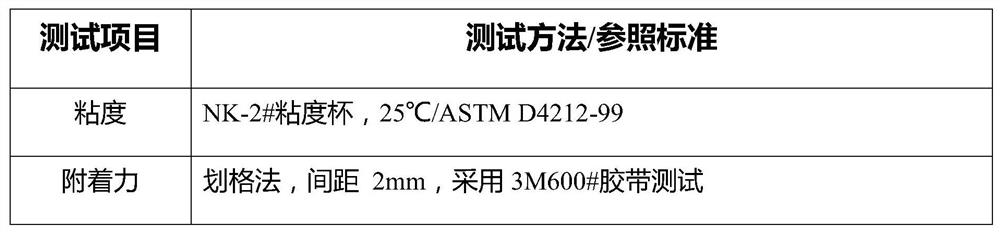

[0025] Thoroughly stir the above-mentioned components, after mixing evenly, spray on the PMMA surface of the PC / PMMA composite board, control the wet film thickness to about 20-30μm, level it in an oven at 50°C for 5min, and then spray it on the PMMA surface of the PC / PMMA composite plate with a radiation energy of 500mJ / cm 2 Cured under UV light. The implementation effect and performance test are shown in Table 2.

Embodiment 2

[0027] This embodiment relates to a high-hardness, high-abrasion and anti-fingerprint UV-curable coating. Concretely comprise each component of mass parts as shown below:

[0028]

[0029] Thoroughly stir the above-mentioned components, after mixing evenly, spray on the PC board, control the wet film thickness to about 20-30μm, level it in an oven at 50°C for 5min, and then spray it on the PC board with an irradiation energy of 500mJ / cm 2 Cured under UV light. The implementation effect and performance test are shown in Table 2.

Embodiment 3

[0031] This embodiment relates to a high-hardness, high-abrasion and anti-fingerprint UV-curable coating. Concretely comprise each component of mass parts as shown below:

[0032]

[0033] Thoroughly stir the above-mentioned components, after mixing evenly, perform flow coating on the PMMA plate, control the wet film thickness to about 15-25 μm, level it in an oven at 50°C for 5 minutes, and then irradiate it with a radiation energy of 500mJ / cm 2 Cured under UV light. The implementation effect and performance test are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com