Colored heat insulation coating with medium and high brightness, and preparation method therof

A heat-insulating coating and high-brightness technology, applied in the coating field, can solve the problems of inability to meet the various requirements of exterior wall coatings, restrictions on use and promotion, high absorption, etc., to reduce the probability of reproduction, good aging resistance and durability Moderate staining and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

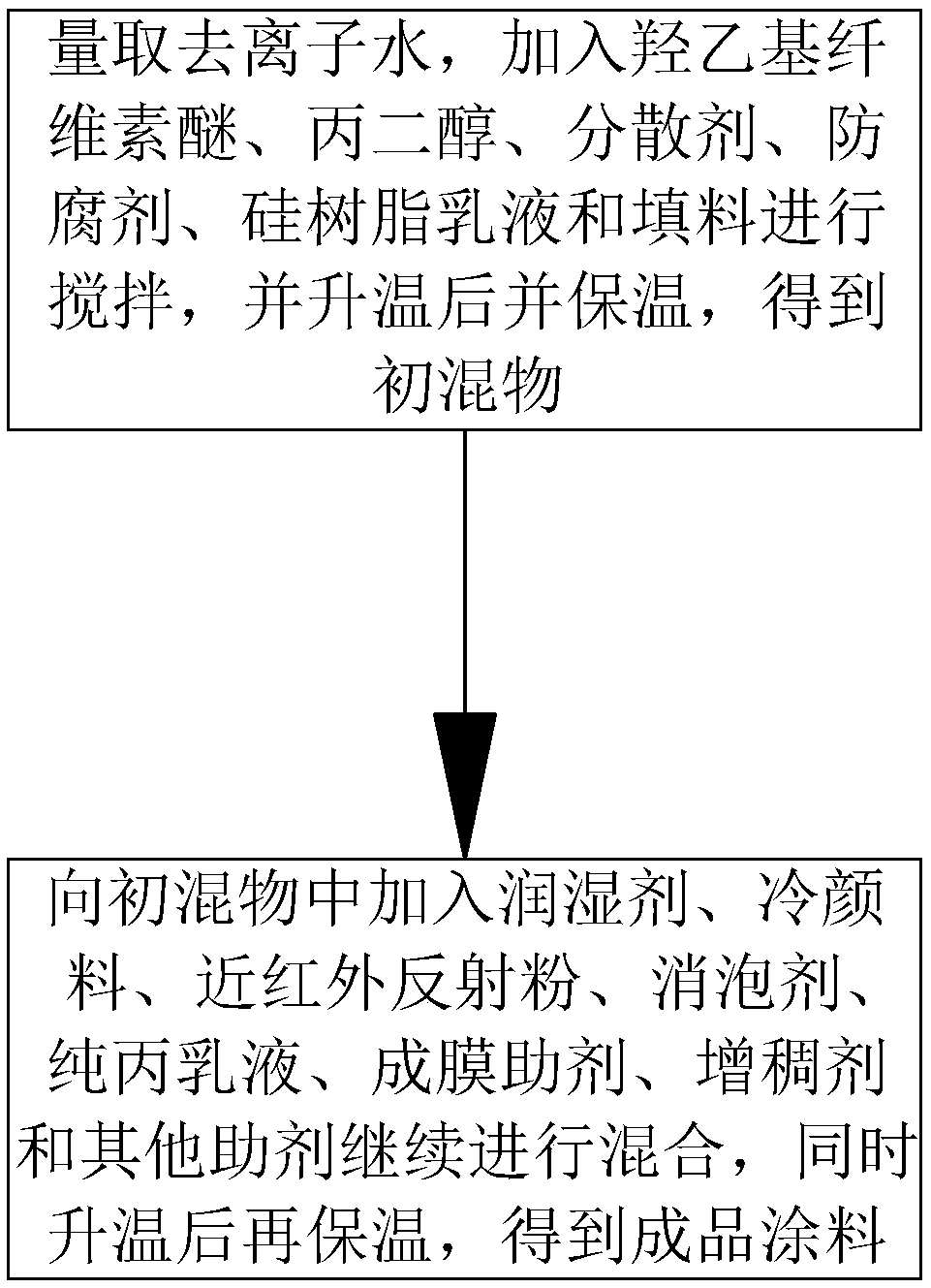

[0036] A kind of preparation method of the color heat insulating coating of middle and high lightness, comprises the following steps:

[0037] Step 1. First measure 100Kg of deionized water, then add 2Kg of hydroxyethyl cellulose ether, 15Kg of propylene glycol, 4Kg of dispersant, 1Kg of preservative, 100Kg of silicone resin emulsion and 200Kg of filler for stirring. Be 500rpm, duration 1h, obtain primary mixture;

[0038] Step 2. Add 1Kg of wetting agent, 150Kg of cold pigment, 10Kg of near-infrared reflective powder, 2Kg of defoamer, 100Kg of pure acrylic emulsion, 1Kg of film-forming aid, 1Kg of thickener and others to the initial mixture in step 1. The additive is 2Kg, continue to mix, the temperature is further raised to 80°C, the stirring speed is 600rpm, the duration is 2h, and the finished coating is obtained after being fully dispersed.

[0039]Among them, the near-infrared reflective powder can be purchased from Huntsman, UK, and the cold pigment can be purchased fr...

Embodiment 2

[0042] A preparation method of a medium-high lightness colored heat-insulating paint, comprising the following steps:

[0043] Step 1. First measure 200Kg of deionized water, then add 3Kg of hydroxyethyl cellulose ether, 20Kg of propylene glycol, 6Kg of dispersant, 3Kg of preservative, 200Kg of silicone resin emulsion and 300Kg of filler for stirring. Be 800rpm, duration 2h, obtain primary mixture;

[0044] Step 2. Add 3Kg of wetting agent, 200Kg of cold pigment, 20Kg of near-infrared reflective powder, 4Kg of defoamer, 200Kg of pure acrylic emulsion, 3Kg of film-forming aid, 3Kg of thickener and others to the initial mixture in step 1. Auxiliary 6Kg, continue to mix, the temperature is further raised to 90°C, the stirring speed is 1000rpm, and the duration is 3h, and the finished coating is obtained after being fully dispersed.

Embodiment 3

[0046] A preparation method of a medium-high lightness colored heat-insulating paint, comprising the following steps:

[0047] Step 1. First measure 150Kg of deionized water, then add 2.5Kg of hydroxyethyl cellulose ether, 17Kg of propylene glycol, 5Kg of dispersant, 2Kg of preservative, 150Kg of silicone resin emulsion and 250Kg of filler for stirring. The temperature rises to 55°C and stirs Rotating speed is 650rpm, duration 1.5h, obtain primary mixture;

[0048] Step 2. Add 2Kg of wetting agent, 180Kg of cold pigment, 15Kg of near-infrared reflective powder, 3Kg of defoamer, 150Kg of pure acrylic emulsion, 2Kg of film-forming aid, 2Kg of thickener and others to the initial mixture in step 1. Auxiliary 4Kg, continue to mix, the temperature is further raised to 85°C, the stirring speed is 800rpm, the duration is 2.5h, and the finished coating is obtained after being fully dispersed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com