Low-volatility clean and anti-oxidative high temperature chain oil and blending method thereof

A high-temperature anti-oxidation, low-volatility technology, used in the petroleum industry, base materials, lubricating compositions, etc., can solve the problems of poor anti-oxidation effect, high consumption of lubricating oil, low applicable temperature, etc., to achieve less coking and reduce oil fume Produces the effect of small evaporation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

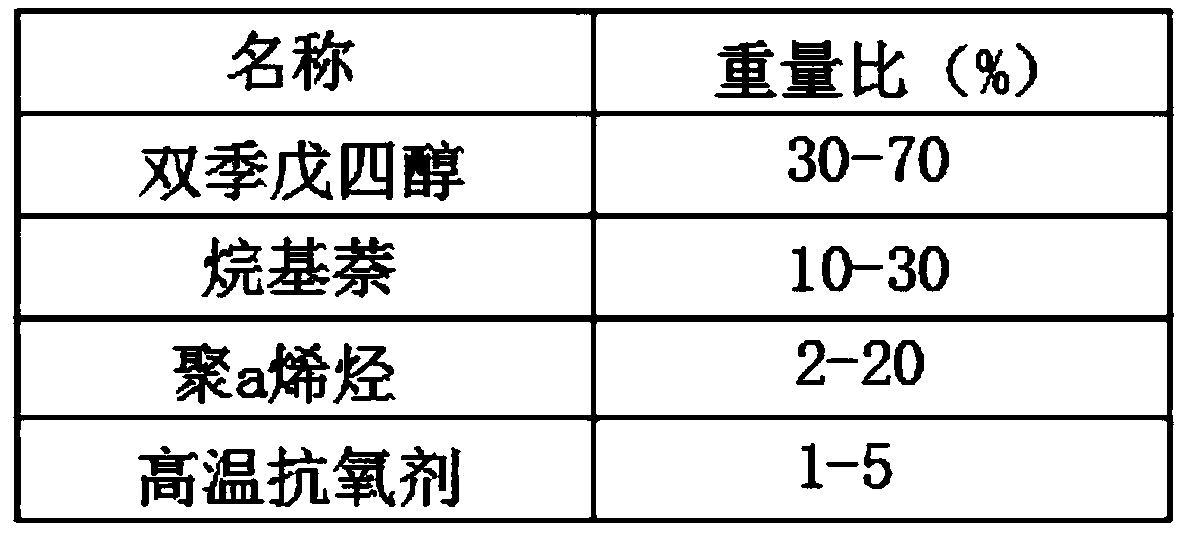

[0022] A low-volatility clean high-temperature anti-oxidation chain oil, each component includes the following components by weight percentage: 70% of dipentaerythritol, 18% of alkyl naphthalene, 10% of polyalpha olefin, and 2% of high-temperature antioxidant.

[0023] Further, the high-temperature antioxidant is an amine-type antioxidant compound.

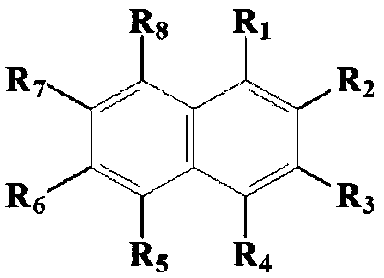

[0024] Further, the structure of alkylnaphthalene is:

[0025]

[0026] Wherein R alkyl is C12-C14 alkyl, and the number of alkylation is 2-4.

[0027] Still further, the kinematic viscosity of alkylnaphthalene at 40°C is 140-320mm2 / s.

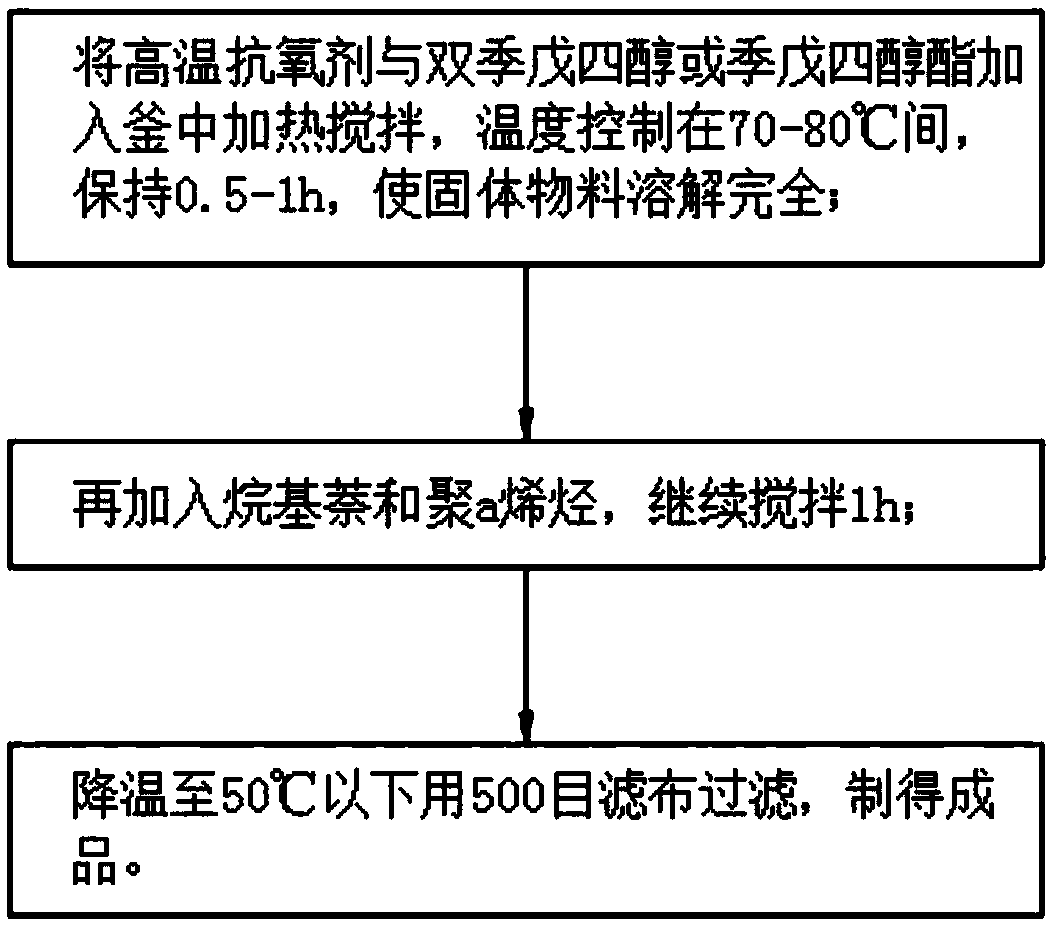

[0028] Still further, a low-volatility clean high-temperature anti-oxidation chain oil and a preparation method thereof, the preparation method comprises the following steps:

[0029] S1: Add the high-temperature antioxidant and dipentaerythritol or pentaerythritol ester into the kettle, heat and stir, control the temperature between 70-80°C, and keep it for 0.5-1h to completely dissolve the ...

Embodiment 2

[0034] A low-volatility clean high-temperature anti-oxidation chain oil, each component includes the following components by weight percentage: 67.95% of dipentaerythritol, 28% of alkyl naphthalene, 2.05% of polyalpha olefin, and 2% of high-temperature antioxidant.

[0035] Further, the high-temperature antioxidant is an amine-type antioxidant compound.

[0036] Further, the structure of alkylnaphthalene is:

[0037]

[0038] Wherein R alkyl is C12-C14 alkyl, and the number of alkylation is 2-4.

[0039] Still further, the kinematic viscosity of alkylnaphthalene at 40°C is 140-320mm2 / s.

[0040] Still further, a low-volatility clean high-temperature anti-oxidation chain oil and a preparation method thereof, the preparation method comprises the following steps:

[0041] S1: Add the high-temperature antioxidant and dipentaerythritol or pentaerythritol ester into the kettle, heat and stir, control the temperature between 70-80°C, and keep it for 0.5-1h to completely dissolve...

Embodiment 3

[0046] A low-volatility clean high-temperature anti-oxidation chain oil, each component includes the following components by weight percentage: 53.5% of dipentaerythritol, 30% of alkyl naphthalene, 14.5% of polyalpha olefin, and 2% of high-temperature antioxidant.

[0047] Further, the high-temperature antioxidant is an amine-type antioxidant compound.

[0048] Further, the structure of alkylnaphthalene is:

[0049]

[0050] Wherein R alkyl is C12-C14 alkyl, and the number of alkylation is 2-4.

[0051] Still further, the kinematic viscosity of alkylnaphthalene at 40°C is 140-320mm2 / s.

[0052] Still further, a low-volatility clean high-temperature anti-oxidation chain oil and a preparation method thereof, the preparation method comprises the following steps:

[0053] S1: Add the high-temperature antioxidant and dipentaerythritol or pentaerythritol ester into the kettle, heat and stir, control the temperature between 70-80°C, and keep it for 0.5-1h to completely dissolve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com