A Double-Telecentric Optical System with Two Optical Paths

An optical system, bi-telecentric technology, applied in optics, optical components, instruments, etc., can solve the problem of inability to obtain SMT package circuit parameters and size information, and achieve outstanding substantive features, high resolution, and high material repetition rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

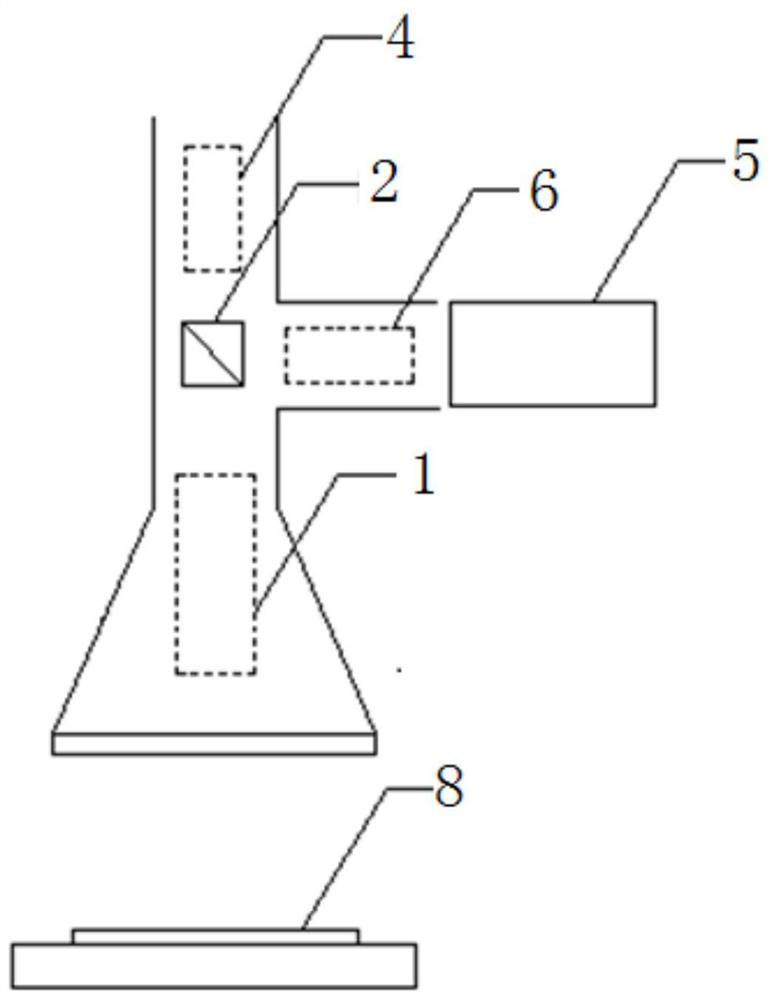

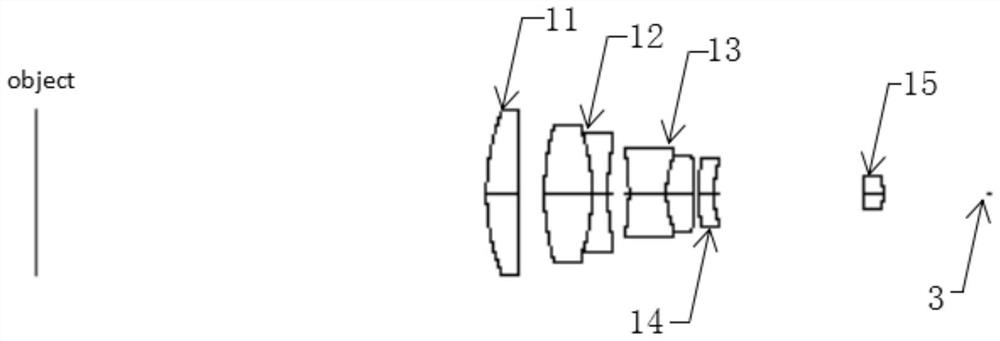

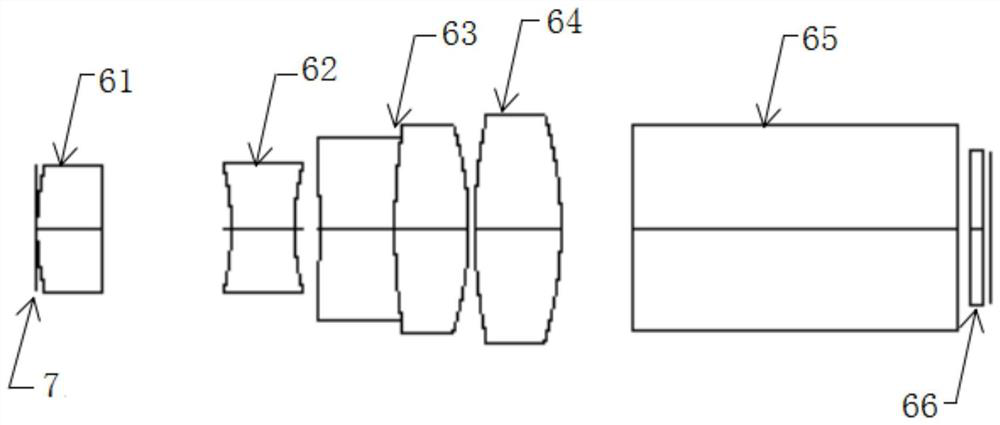

[0029] combine Figure 1 to Figure 10 As shown, this embodiment provides a double-optical-path double-telecentric optical system, the double-light-path double-telecentric optical system includes a projection system and an imaging system, and the imaging system is sequentially provided with a common optical path objective lens from the object plane to the image plane Group 1, dichroic prism 2, diaphragm one 3 and imaging objective lens group 4, the projection system includes illumination system 5, projection objective lens group 6, diaphragm two 7, dichroic prism 2 and common optical path objective lens from the illumination system to the object plane Group 1, the imaging system and the projection system share the common optical path objective lens group 1 and the dichroic prism 2, and the projection system projects the modulated fringe light generated by the illumination system 5 onto the object surface, the The imaging system images the fringe light information reflected by t...

Embodiment 2

[0039] The dual optical path bi-telecentric optical system provided in this embodiment is only different from that of Embodiment 1 in that: the refractive power of the first lens 11 is 0.0092, and the refractive power of the second lens 12 is 0.0027. The third lens 13 has a refractive power of -0.0140, the fourth lens 14 has a refractive power of -0.0046, the fifth lens 15 has a refractive power of 0.0062; the sixth lens 61 has a refractive power of 0.0330, The refraction power of the seventh lens 62 is -0.0811, the refraction power of the eighth lens 63 is 0.0187, the refraction power of the ninth lens 64 is 0.0328; the refraction power of the twelfth lens 41 is -0.0022 , the focal power of the thirteenth lens 42 is 0.0079, the focal power of the fourteenth lens 43 is -0.0004, the focal power of the fifteenth lens 44 is 0.0055, and the focal power of the sixteenth lens 46 is The degree is 0.0048.

[0040] To sum up, it can be seen that the double-optical path double-telecent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com