High-energy-density zinc-nickel battery positive electrode manufacturing method

A zinc-nickel battery and battery positive electrode technology, which is applied to battery electrodes, nickel batteries, alkaline battery electrodes, etc., can solve the problems of uneven battery current distribution, low utilization rate of active materials, and loose combination, so as to improve charging acceptance. ability, reduce softening and shedding, and reduce the effect of internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

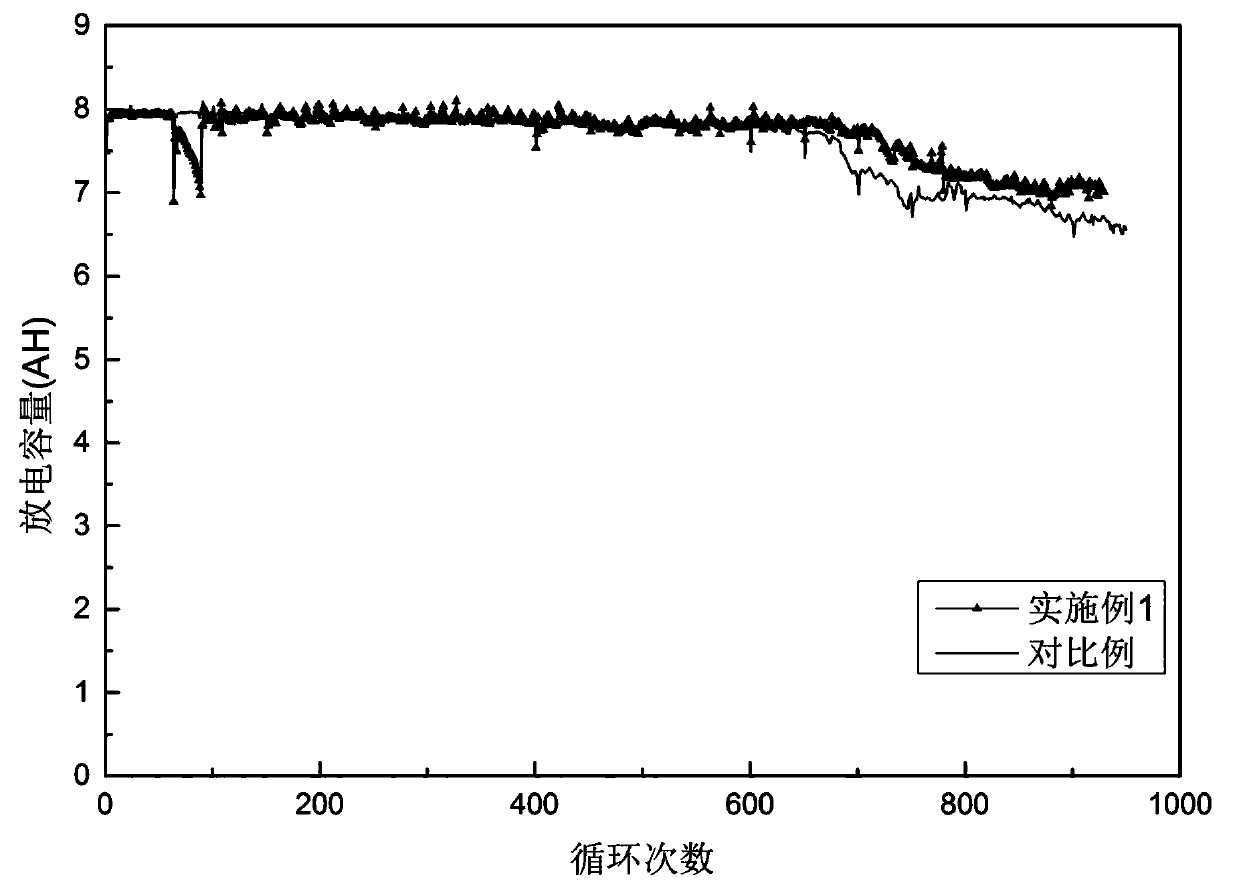

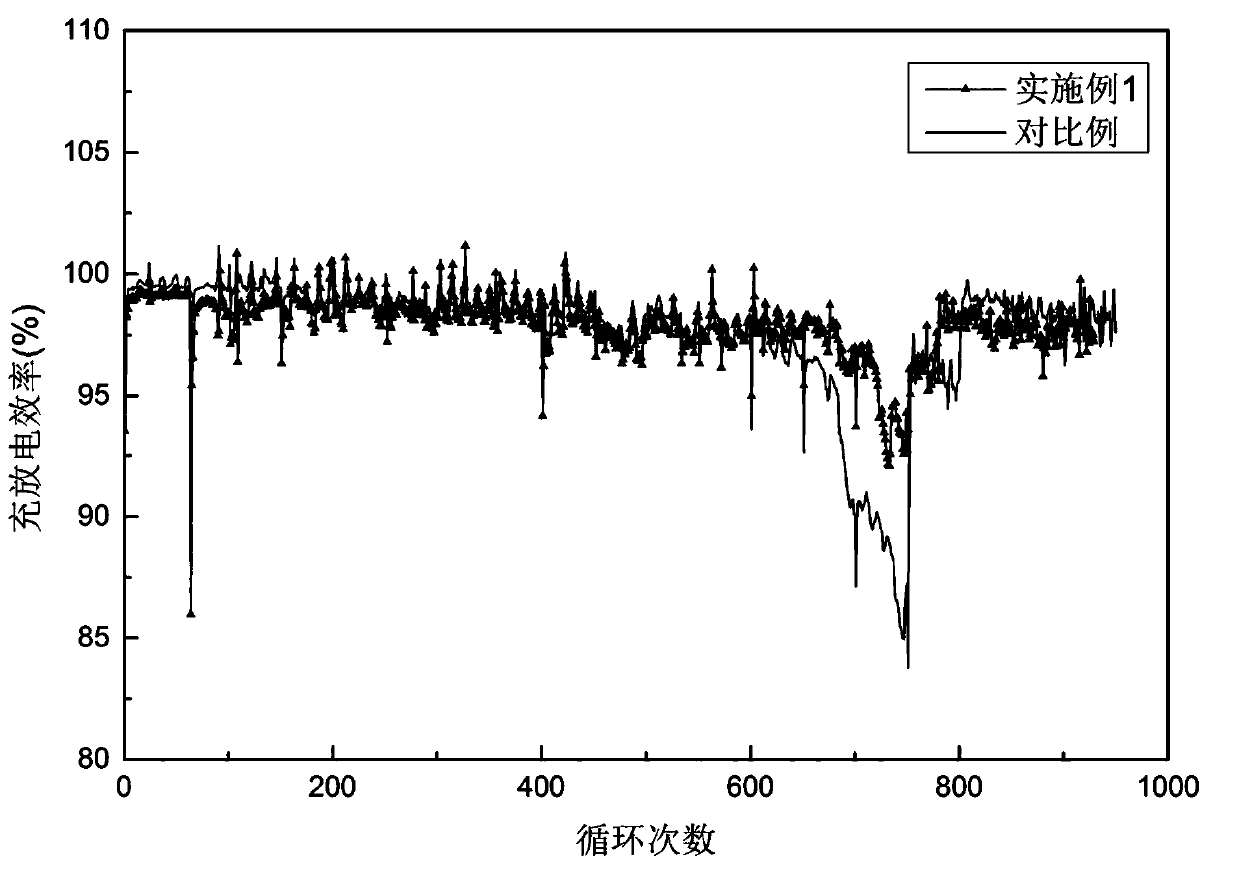

Embodiment 1

[0036] A method for preparing a positive electrode of a high specific energy zinc-nickel battery, comprising the following steps:

[0037] a) Mix the raw material A and the thickener evenly to prepare the slurry A. The raw material A is composed of an active material and a conductive agent; the thickening agent is methyl cellulose, and the active material is Ni(OH) 2 , the conductive agent is polyacetylene; the weight ratio of the conductive agent and the active material is 0.8:100, and the addition amount of the thickener is 0.5wt% of the sum of the weight of the conductive agent and the active material;

[0038] b) The NiCl 2 Dissolved in water to obtain 0.1mol / L NiCl 2 The solution was stirred at 600 rpm for 8 minutes, and slurry A and NiCl were added. 2 The solution weight of 0.2wt% naphthalenesulfonic acid formaldehyde condensate, continue to stir at 800rpm for 5 minutes to prepare slurry B; slurry A and NiCl 2 The weight ratio of the solution is 2:1;

[0039] c) Add ...

Embodiment 2

[0043] A method for preparing a positive electrode of a high specific energy zinc-nickel battery, comprising the following steps:

[0044] a) Mixing raw material A and thickening agent uniformly to obtain slurry A, raw material A is composed of active material and conductive agent; thickening agent is hydroxypropyl methylcellulose, and active material is Ni(OH) 2 , the conductive agent is polythiophene; the weight ratio of the conductive agent and the active material is 0.8:85, and the addition amount of the thickener is 0.5wt% of the sum of the weight of the conductive agent and the active material;

[0045] b) The NiCl 2Dissolved in water to obtain 0.1mol / L NiCl 2 The solution was stirred at 600 rpm for 3 minutes, and slurry A and NiCl were added. 2 The solution weight of 0.25wt% naphthalenesulfonic acid formaldehyde condensate, continue to stir at 600rpm for 5 minutes to prepare slurry B; slurry A and NiCl 2 The weight ratio of the solution is 2:1.2;

[0046] c) Add pol...

Embodiment 3

[0050] A method for preparing a positive electrode of a high specific energy zinc-nickel battery, comprising the following steps:

[0051] a) Mix the raw material A and the thickener evenly to prepare the slurry A. The raw material A is composed of an active material and a conductive agent; the thickening agent is sodium carboxymethyl cellulose, and the active material is Ni(OH) 2 The composite material, the conductive agent is polypyrrole; the weight ratio of the conductive agent and the active material is 2:150, and the addition amount of the thickener is 1.2wt% of the sum of the weight of the conductive agent and the active material;

[0052] b) The NiCl 2 Dissolved in water to obtain 1mol / L NiCl 2 The solution was stirred at 800 rpm for 10 minutes, and slurry A and NiCl were added. 2 The solution weight of 0.5wt% naphthalenesulfonic acid formaldehyde condensate, continue to stir at 700rpm for 15 minutes to prepare slurry B; slurry A and NiCl 2 The weight ratio of the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com