Process for synthetically utilizing sweet potato for multi-stage co-production of starch and concentrated clear juice

A sweet potato and clear juice technology, applied in the field of food processing, can solve the problems affecting the production cost of enterprises, high cost of sewage treatment, and difficult treatment, and achieve the effects of ensuring production continuity, high product market acceptance, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

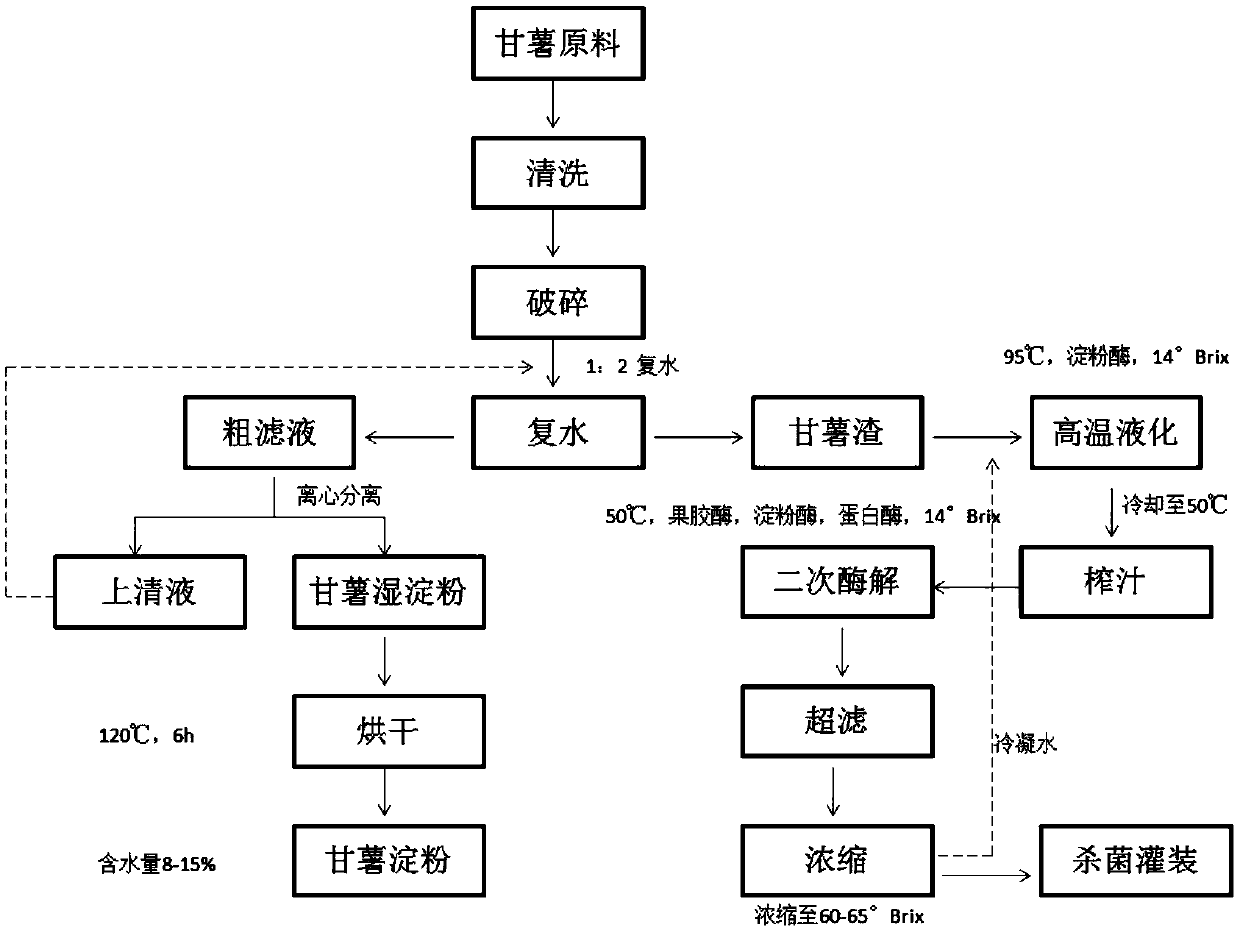

[0084] The process of comprehensively utilizing sweet potato for multi-stage co-production of starch and concentrated clear juice comprises the following steps:

[0085] (1) Carry out two-stage cleaning and draining of the sweet potato raw material, hammer crushing to 40 mesh, and obtain the sweet potato raw material after crushing;

[0086] (2) Add water to the crushed sweet potato raw material in step (1), the crushed sweet potato raw material and water mass ratio are 1:2, after stirring for about 10min, filter through a 60 mesh vibrating screen to obtain the crude filtrate respectively and sweet potato residue;

[0087] (3) The crude filtrate is separated by a disc centrifuge, the centrifuge disc rotating speed is 7500r / min, the supernatant and sweet potato wet starch are obtained after centrifugation, and the sweet potato wet starch is dried at a drying temperature of 120°C. The drying time is 5 hours, and the sweet potato dry starch is obtained, and the moisture content ...

Embodiment 2

[0100] The process of comprehensively utilizing sweet potato for multi-stage co-production of starch and concentrated clear juice comprises the following steps:

[0101] (1) Carry out two-stage cleaning and draining of the sweet potato raw material, hammer crushing to 40 mesh, and obtain the sweet potato raw material after crushing;

[0102] (2) Add water to the crushed sweet potato raw material in step (1), the crushed sweet potato raw material and water mass ratio are 1:2, after stirring for about 10min, filter through a 60 mesh vibrating screen to obtain the crude filtrate respectively and sweet potato residue;

[0103] (3) The crude filtrate is separated by a disc centrifuge, the centrifuge disc rotating speed is 6000r / min, the supernatant and sweet potato wet starch are obtained after centrifugation, and the sweet potato wet starch is dried at a drying temperature of 120°C. The drying time is 5 hours, and the sweet potato dry starch is obtained, and the moisture content ...

Embodiment 3

[0115] The process of comprehensively utilizing sweet potato for multi-stage co-production of starch and concentrated clear juice comprises the following steps:

[0116] (1) Carry out two-stage cleaning and draining of the sweet potato raw material, hammer crushing to 40 mesh, and obtain the sweet potato raw material after crushing;

[0117] (2) Add water to the crushed sweet potato raw material in step (1), the crushed sweet potato raw material and water mass ratio are 1:2, after stirring for about 10min, filter through a 60 mesh vibrating screen to obtain the crude filtrate respectively and sweet potato residue;

[0118] (3) The crude filtrate is separated by a disc centrifuge, the centrifuge disc speed is about 5500r / min, and the supernatant and sweet potato wet starch are obtained after centrifugation, and the sweet potato wet starch is dried at a drying temperature of 120°C , the drying time is 5 hours, and the sweet potato dry starch is obtained, and the moisture conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com