EDTA-2Na-modified phosphate bonding agent and preparation method and application thereof

A disodium ethylenediamine tetraacetate and phosphate technology, which is applied in the manufacture of tools, casting molding equipment, metal processing equipment, etc., can solve the problems of poor moisture absorption resistance, unstable performance, and low adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

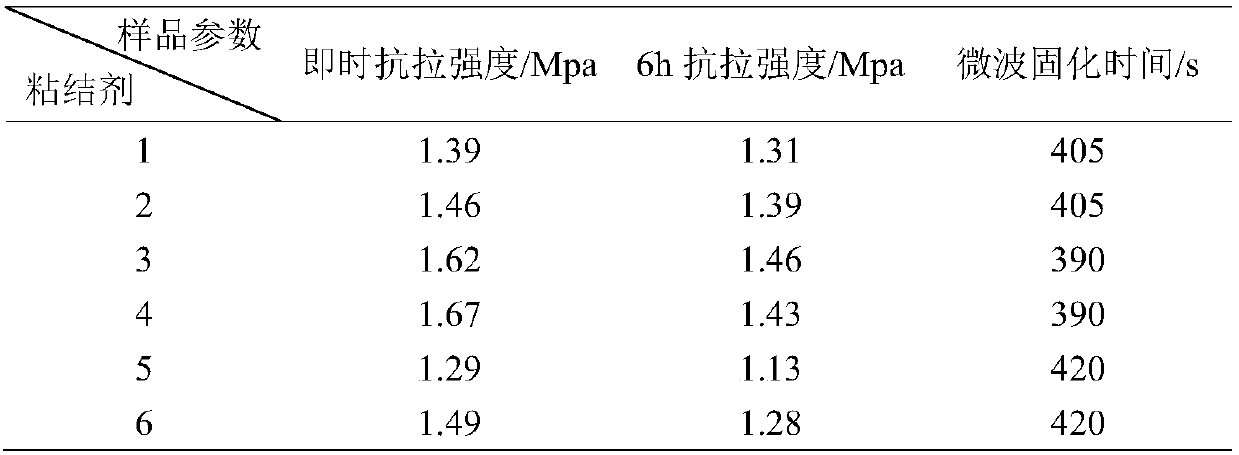

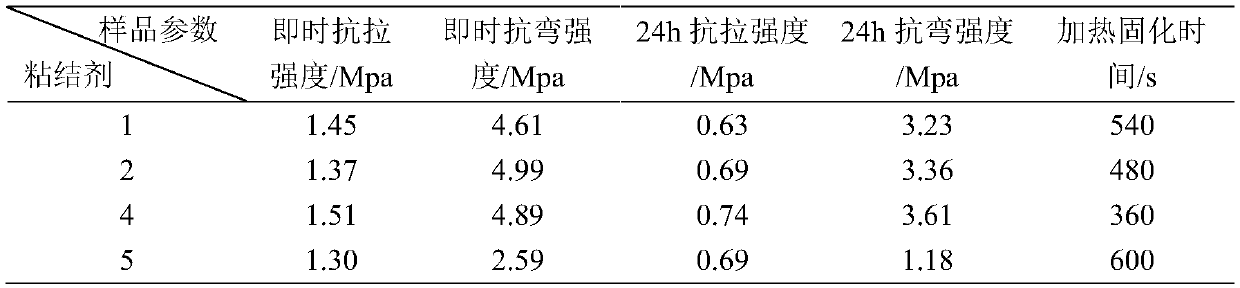

Embodiment 1

[0049] Raw material ratio:

[0050] 338g of 85% industrial phosphoric acid, 68g of 320 mesh aluminum hydroxide powder, 12g of boric acid, 4g of silicic acid, 8g of light magnesium oxide, 0.25g of copper oxide, 0.25g of iron sulfate, 8g of EDTA-2Na, 200g of purified water.

[0051] Preparation steps:

[0052] (1) Weigh each component by the above proportioning ratio;

[0053] (2) Add industrial phosphoric acid into the reaction kettle and heat to 110-120°C while stirring;

[0054] (3) Add 1 / 2 of the aluminum hydroxide powder into the reaction kettle, stir slowly, and continue to heat up to 110-120°C;

[0055] (4) When the reaction solution is clear and transparent, add the remaining 1 / 2 aluminum hydroxide powder into the reaction kettle, keep the temperature stable, and continue stirring until the reaction solution is transparent.

[0056] (5) Add 50ml of water, stir and heat to 110-120°C;

[0057] (6) Add boric acid and silicic acid powder, continue heating and stirring un...

Embodiment 2

[0064] Raw material ratio:

[0065] 338g of 85% industrial phosphoric acid, 68g of 320 mesh aluminum hydroxide powder, 12g of boric acid, 4g of silicic acid, 8g of light magnesium oxide, 0.25g of copper oxide, 0.25g of iron sulfate, 12g of EDTA-2Na, 200g of purified water.

[0066] The preparation steps are the same as in Example 1.

Embodiment 3

[0068] Raw material ratio:

[0069]338g of 85% industrial phosphoric acid, 68g of 320 mesh aluminum hydroxide powder, 12g of boric acid, 4g of silicic acid, 8g of light magnesium oxide, 1g of copper oxide, 0.25g of iron sulfate, 10g of EDTA-2Na, 200g of purified water.

[0070] The preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average tensile strength | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

| Average tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com