Graphene modified highly-weathering-resistant and highly-rebound nanometer polymer seam filling material and preparation method thereof

A nano-polymer and graphene modification technology, applied in the field of anti-corrosion materials, can solve problems such as poor weather resistance, and achieve the effects of increasing overall performance, increasing life, increasing weather resistance and comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] A graphene-modified high-weather-resistance and high-resilience nano-polymer gap-filling material, including main agent A component and auxiliary agent B component, and the mass ratio of A component to B component is 1:1;

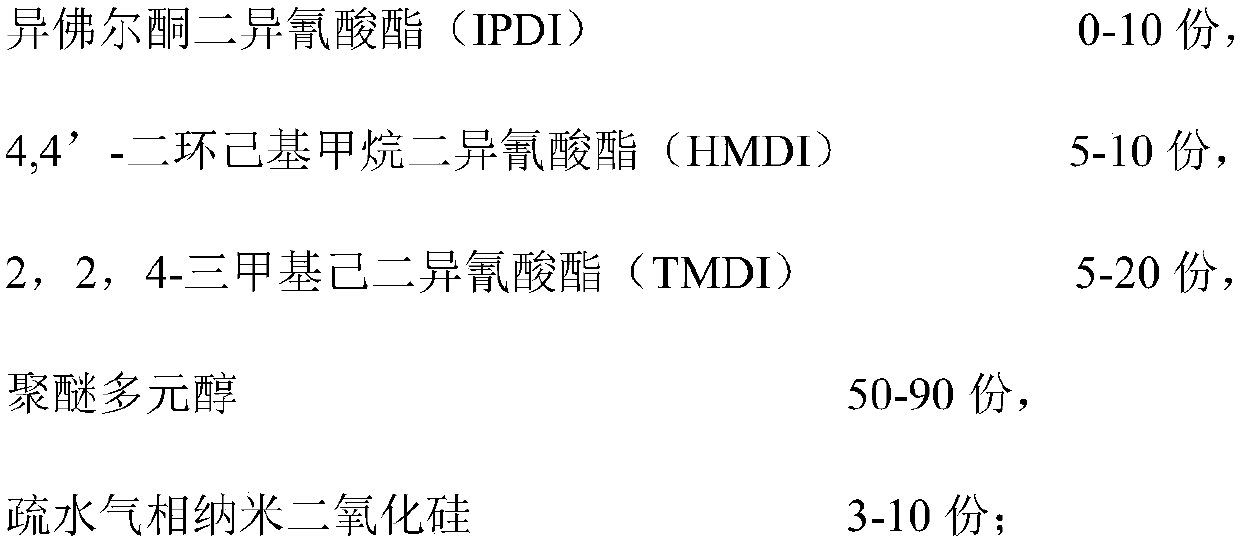

[0066] Wherein, component A is made of raw materials comprising the following parts by weight:

[0067]

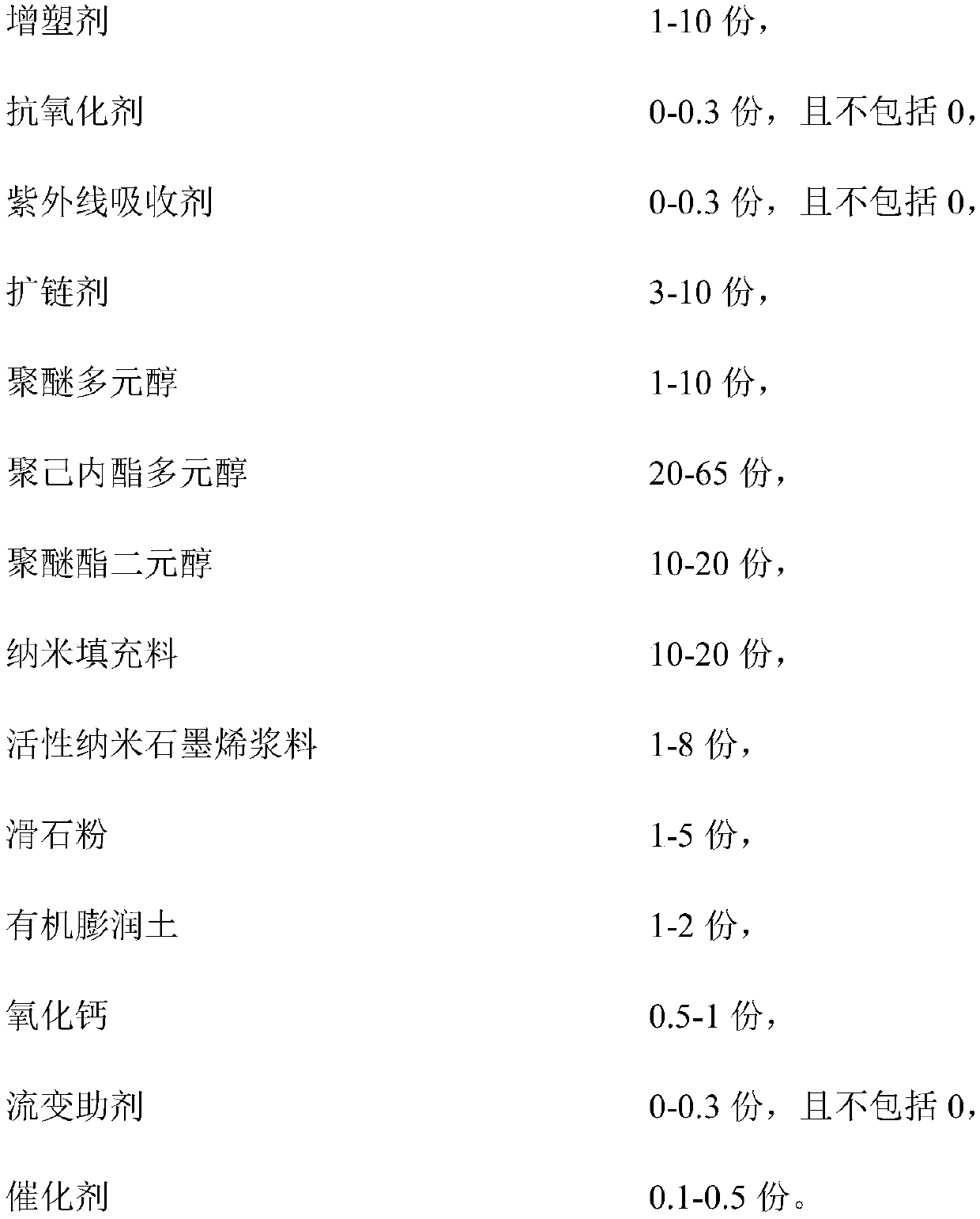

[0068] Component B is made from raw materials including the following parts by weight:

[0069]

[0070]

Embodiment 2

[0072] A graphene-modified high-weather-resistance and high-resilience nano-polymer gap-filling material, including main agent A component and auxiliary agent B component, and the mass ratio of A component to B component is 1:1;

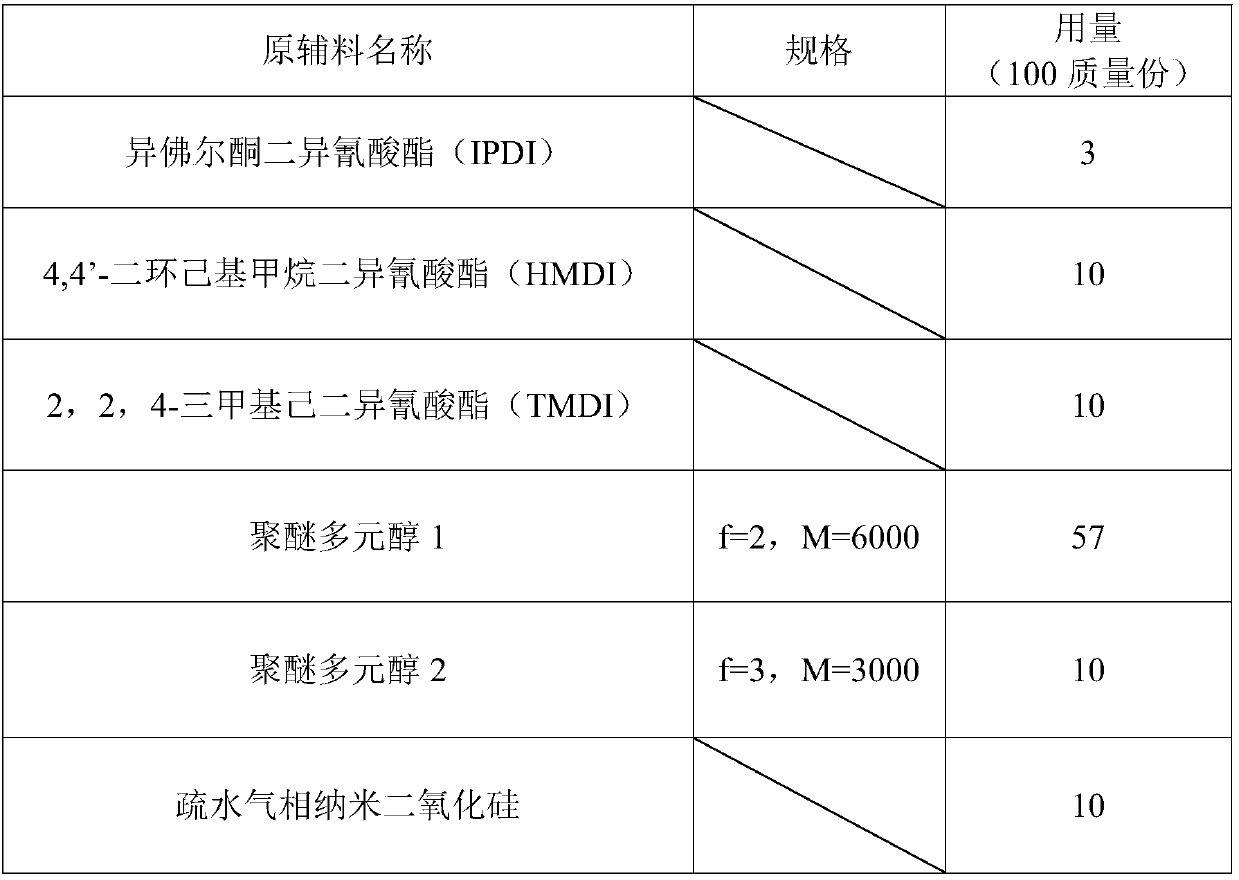

[0073] Wherein, component A is made of raw materials comprising the following parts by weight:

[0074]

[0075] Component B is made from raw materials including the following parts by weight:

[0076]

[0077]

Embodiment 3

[0079] A graphene-modified high-weather-resistance and high-resilience nano-polymer gap-filling material, including main agent A component and auxiliary agent B component, and the mass ratio of A component to B component is 1:1;

[0080] Wherein, component A is made of raw materials comprising the following parts by weight:

[0081]

[0082]

[0083] Component B is made from raw materials including the following parts by weight:

[0084]

[0085]

[0086] The preparation method of the graphene-modified high-weather-resisting high-resilience nano-polymer gap-filling material described in embodiment 1-3, the method comprises the steps:

[0087] A. Preparation of component A:

[0088] (1) Treatment of hydrophobic fumed nano-silica: mix hydrophobic fumed nano-silica, dissolved intermediate and active coupling agent in a weight ratio of 1:6:0.005, stir and disperse at a speed of 1800r / min for 4- 5h, after mixing evenly, put it into an oven at 110°C and bake for 36-48h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com