Treatment device and method of dedusting ash in sintering electric field

A technology of electric field dust removal and treatment device, which is applied in the fields of chemical production and comprehensive utilization of metallurgical solid waste, can solve the problem that dust removal dust cannot be effectively treated, and achieve the effect of reducing investment cost, effective treatment and easy technology promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

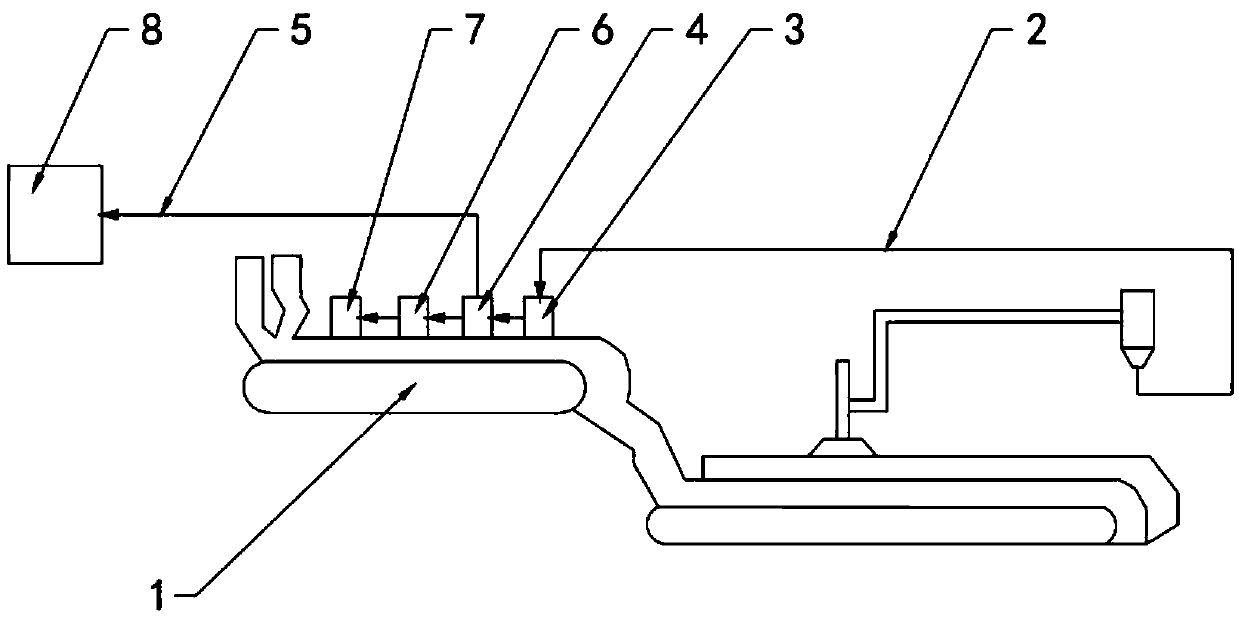

[0053] see figure 1 , the processing device for sintering electric field dedusting ash includes dust removal ash conveying device, leaching tank 3, solid-liquid separation unit 4, pipe chain conveyor 5 and evaporation concentration unit 6, dedusting ash conveying device, leaching tank 3 and solid-liquid separation unit 4 Connected in sequence, the solid material outlet of the solid-liquid separation unit 4 is connected to the pipe chain conveyor 5, and the liquid material outlet of the solid-liquid separation unit 4 is connected to the evaporation concentration unit 6 through a pipeline. The dedusting ash conveying device in this embodiment is a pneumatic conveying pipeline 2, and the leaching tank 3, the solid-liquid separation unit 4, and the evaporation concentration unit 6 are directly assembled on the sintering machine 1, so as to avoid the dedusting ash and the iron content after the potassium fertilizer is extracted from the dedusting ash. Long-distance transportation o...

Embodiment 2

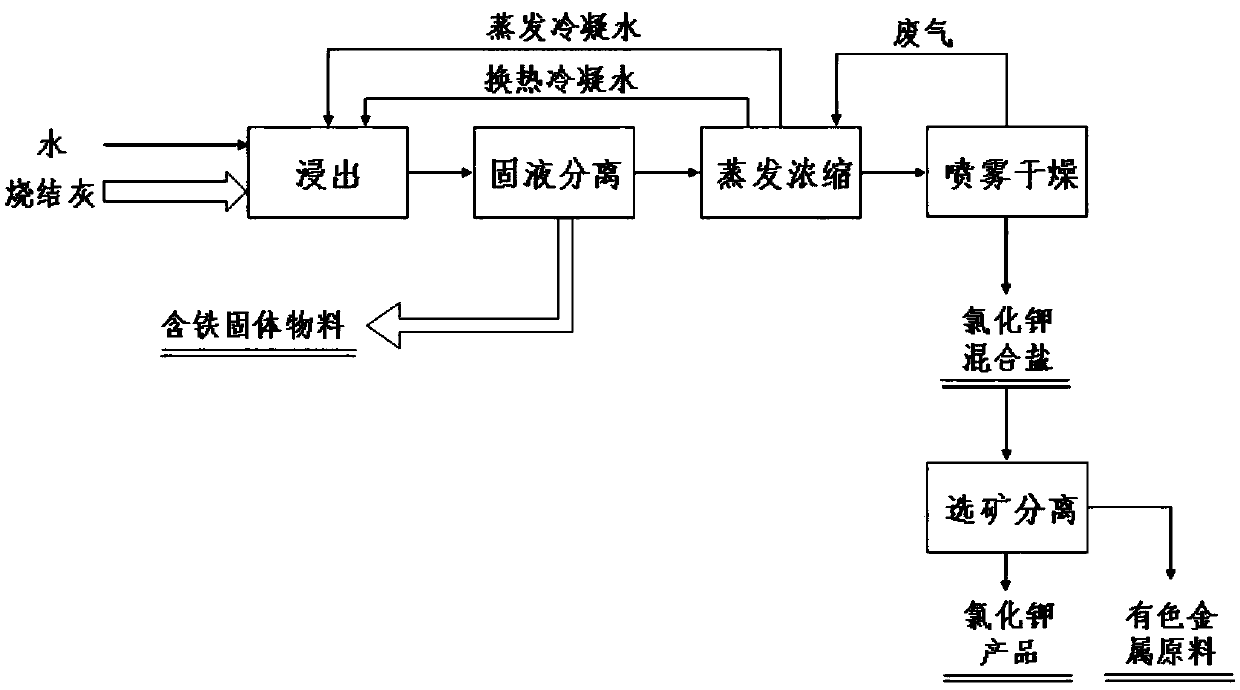

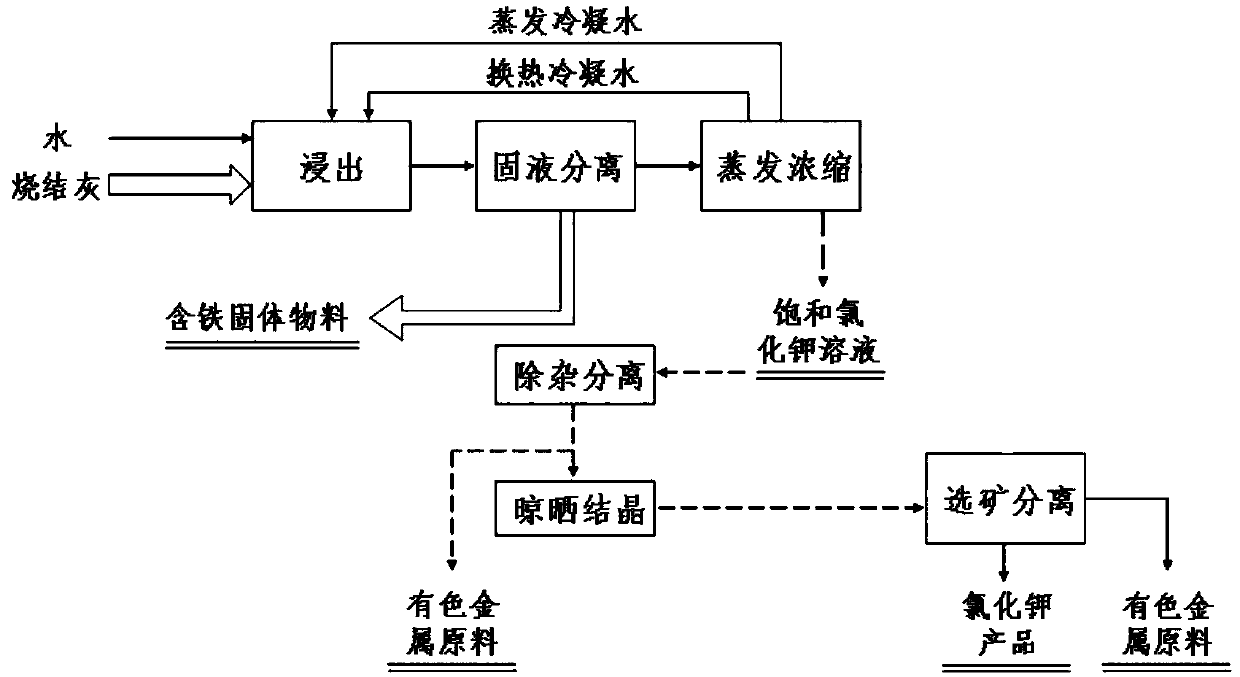

[0080] see image 3 , in this embodiment, the pneumatic conveying pipeline 2 is respectively linked to the fourth electric field dedusting ash discharge port of the head of the sintering machine 1, and the end of the pipeline is connected to the leaching tank 3. After the sintering dust is discharged, it is transported to the leaching tank 3 through a pipeline, and tap water 1.5 times the total weight of the dust is added to stir and leach. After stirring for 30 minutes, the slurry is sent to a plate and frame filter press for pressure filtration, and the obtained filtrate is pumped to the evaporation concentration unit 6 for heat exchange and concentration, and the solid material obtained by pressure filtration is transported to the sintering batching workshop 8 for use through a pipe chain.

[0081] A mechanical vapor recompression device is used to heat and concentrate the leaching solution until the potassium chloride in the leaching solution is saturated, and the steam ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com