In-vitro double dynamic degradation performance analysis device for medical magnesium alloy implant material

An implant material and magnesium alloy technology are applied in the field of devices for in vitro dual dynamic degradation performance analysis of medical magnesium alloy implant materials. Manpower and material resources and other issues, to save manpower and time, realize real-time measurement, and increase measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

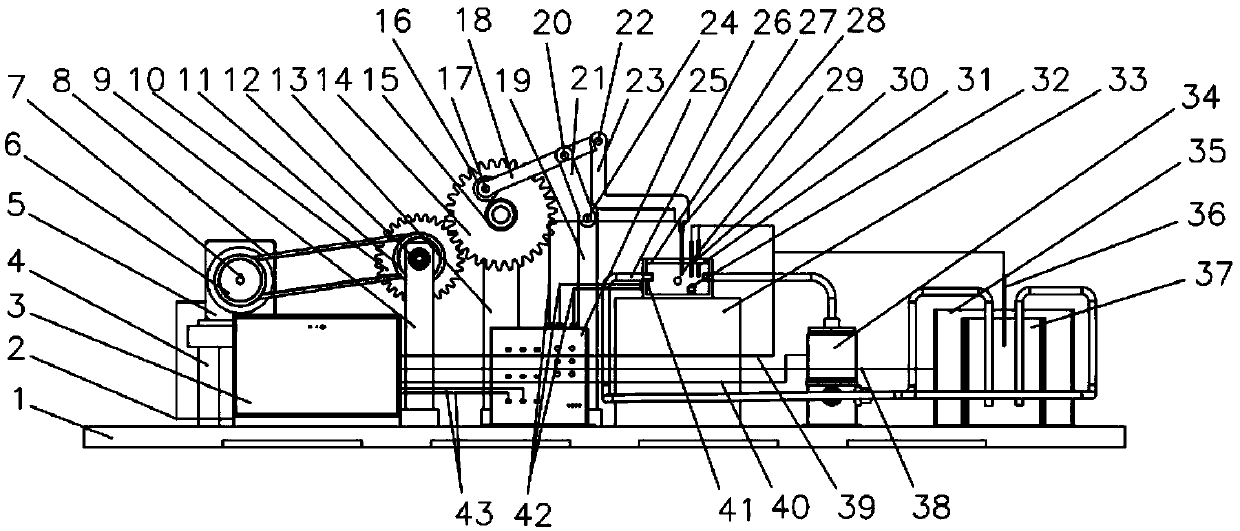

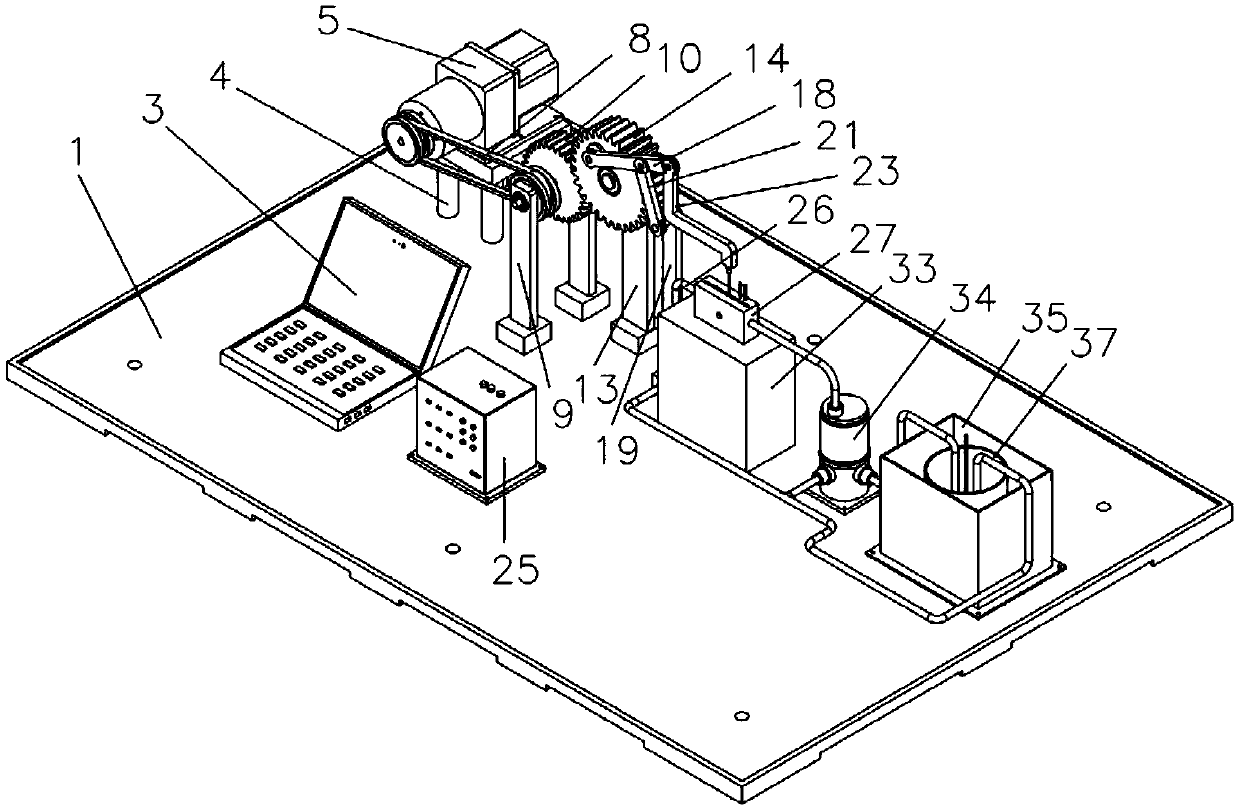

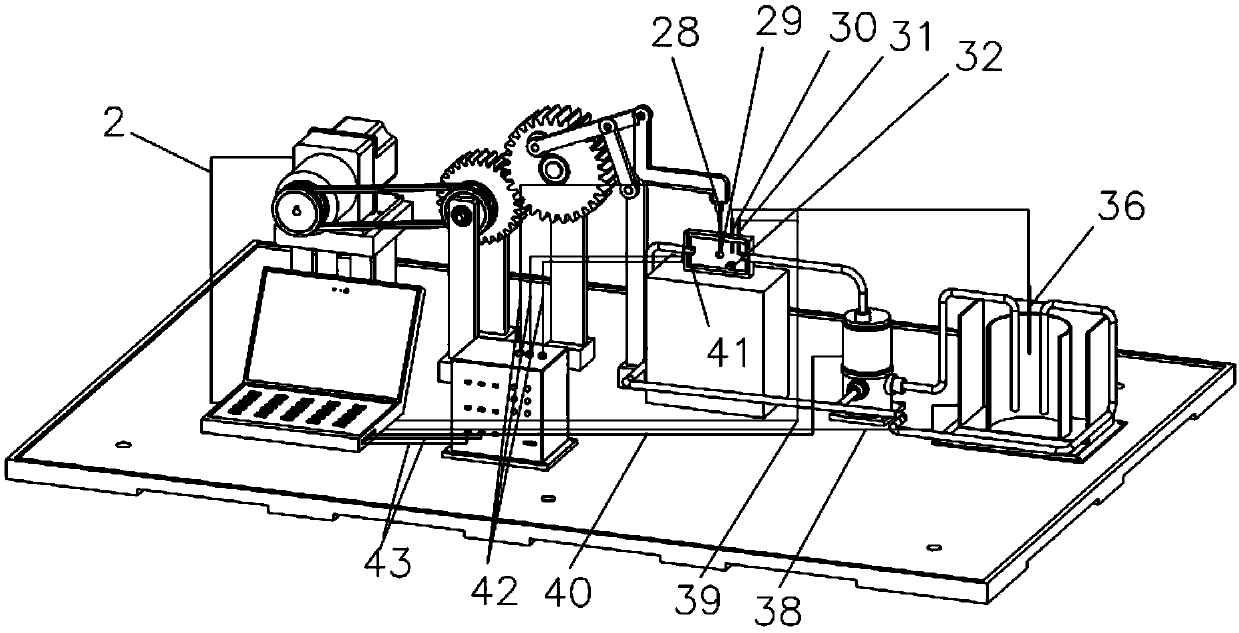

[0041] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0042] see figure 1 , figure 2 , image 3 , Description of reference signs: base 1, motor control line 2, computer 3, motor support seat 4, motor 5, pulley 6, motor shaft key 7, belt 8, pinion shaft support frame 9, pinion 10, pulley 11, Pinion bearing 12, large gear shaft support frame 13, large gear 14, large gear bearing 15, connecting rod connection block 16, first pin 17, first connecting rod 18, connecting rod shaft support frame 19, second pin 20, Second connecting rod 21, third pin 22, third connecting rod 23, fourth pin 24, electrochemical workstation 25, infusion pipeline 26, sample tank 27, swing rod 28, sample 29, first thermometer 30, pH Meter 31, flow rate flow meter 32, sample tank support seat 33, speed-regulating peristaltic pump 34, constant temperature tank 35, second thermometer 36, liquid storage tank 37, constant temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com