Bis(fluorosulfonyl)imide metal salt and method for preparing same

A technology of bisfluorosulfonimide and manufacturing method, which is applied in the fields of final product manufacturing, nitrogen and non-metallic compounds, sustainable manufacturing/processing, etc., can solve the problems such as unrecorded lithium salt molding methods, and achieve the goal of not being easy to scatter, not easy to Moisture absorption, easy handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

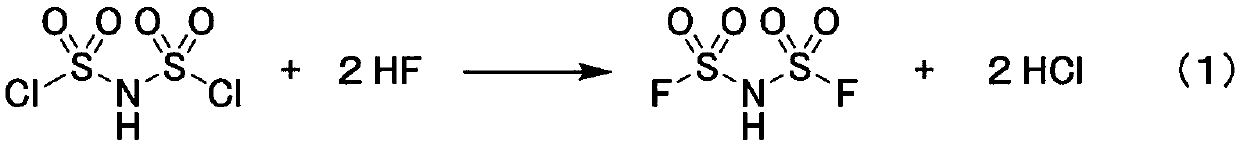

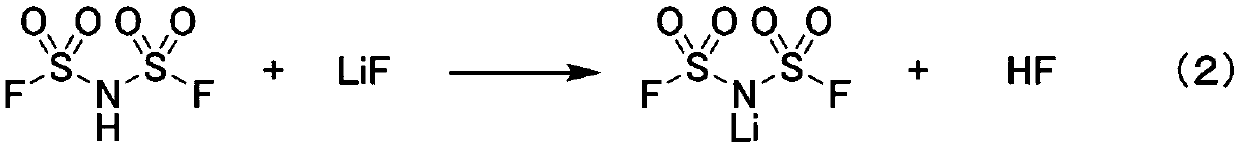

Method used

Image

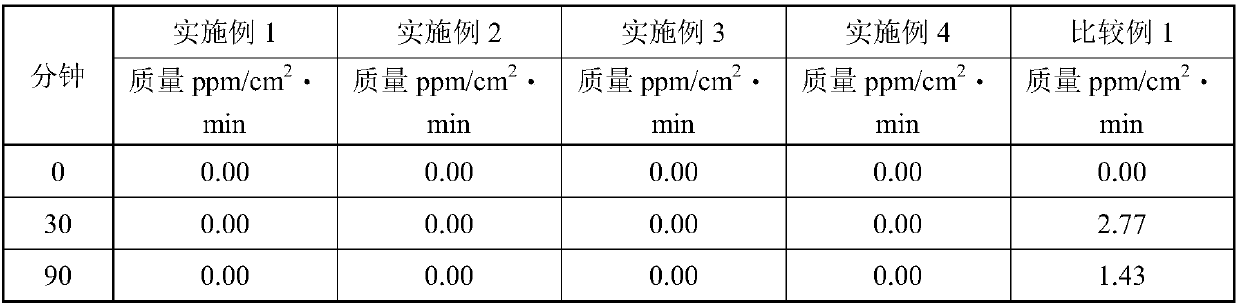

Examples

Embodiment 1

[0135] 11.70 g (0.45 mol) of LiF was weighed into the PFA reaction container. The reaction container was ice-cooled, and 95.9 g (0.53 mol) of HFSI [bisfluorosulfonimide] was charged. The reaction solution was heated to 120° C., and reacted for 1.5 hours. The reaction solution was heated under reduced pressure at 10 hPa, 140-145° C. for 2 hours. As a result, 73 g (molten state) of LiFSI was obtained.

[0136] The obtained LiFSI was sucked up with a glass pipette while maintaining the temperature of 140 to 145° C., and quickly dropped on a SUS304 plate heated to 60° C., and solidified to obtain pellets. The mass average particle diameter of the cured pellets was 4.8 mm. Moisture content was 54 mass ppm. In addition, the residual solvent amount was not more than the detection limit (1 mass ppm or less). The bulk specific gravity of the obtained pellets was 1.12. The above reactions and operations are carried out in a dry room with a dew point below -50°C.

Embodiment 2

[0138] 905 g (5.00 mol) of HFSI [bisfluorosulfonimide] and 132 g (5.10 mol) of LiF were charged into a stainless steel reaction vessel equipped with a nitrogen gas inlet tube and a reflux tube. While stirring the reaction solution, it heated to 150 degreeC. Thereafter, the pressure was reduced, and the reaction solution was heated at 10 hPa at 145 to 150° C. for 2 hours. As a result, 890 g (4.76 mol) of LiFSI (molten state) was obtained.

[0139] The reaction solution obtained in this way was connected to a transmission steel belt type granulation device (ROTOFORMM1) manufactured by SANDVIK Co., Ltd. through a heating pipe, and was pressure-fed thereto. The melt is extruded onto the transmission steel belt under certain conditions. Scrape the molten liquid extruded until the transmission steel belt makes one revolution directly with a scraper, and obtain pellets after one revolution. At this time, the crystal nucleation time was 1 minute, the crystal growth time was 2 minut...

Embodiment 3

[0142] 905 g (5.00 mol) of HFSI [bisfluorosulfonimide] and 129 g (4.98 mol) of LiF were charged into a stainless steel reaction vessel equipped with a nitrogen gas inlet tube and a reflux tube. Stirring the reaction solution, it heated at 150 degreeC, and reacted for 1.5 hours. The reaction solution was heated under reduced pressure at 10 hPa, 145-150° C. for 2 hours. As a result, 890 g (4.76 mol) of LiFSI (molten state) was obtained.

[0143]A pipe for taking out was connected to this reactor, and the LiFSI melt was taken out by pressurizing from a nitrogen gas introduction pipe. The melt was drawn into a mold having a depth of 1 cm, a width of 1.75 cm, and a width of 2 cm, and the mold was cooled at 50° C. to obtain a massive LiFSI shaped body. The obtained LiFSI shaped body was measured with a caliper, and the minimum length was 10 mm. In addition, the water content was 7 mass ppm. In addition, the residual solvent amount was not more than the detection limit. The abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com