Preparation method of semen persicae processed decoction piece formula granules

A technology of formula granules and decoction pieces, which is applied in the direction of medical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of formula granules processed with peach kernels that have not yet been seen, and improve the extraction transfer rate, Reduce the effect of degradation damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

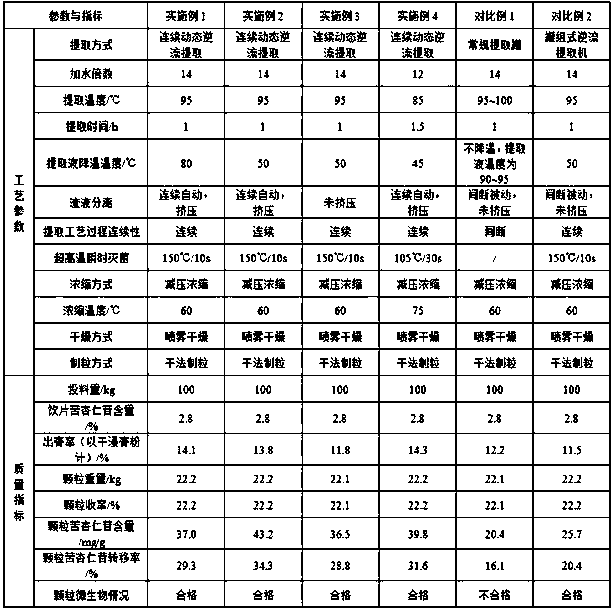

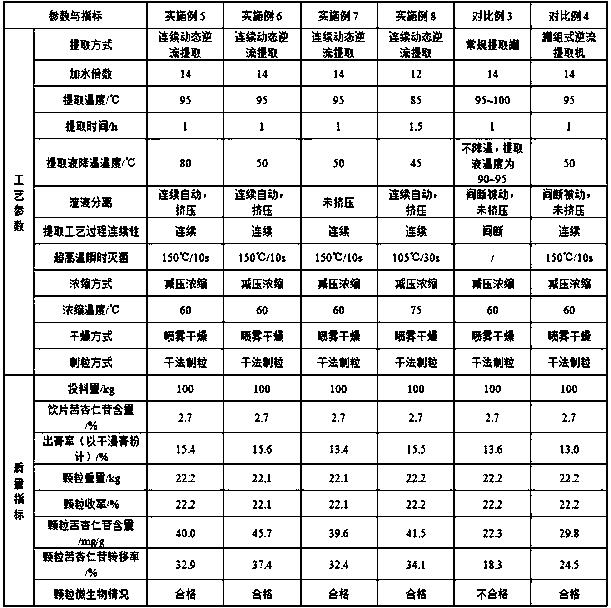

Examples

Embodiment 1

[0043] A preparation method for the formula granules of peach kernels, comprising the steps of:

[0044] a, the peach kernel decoction pieces are broken into 0.5cm coarse particles;

[0045] b. Continuously input the coarse particles into the leaching tube of the spiral continuous countercurrent extractor (two-stage 10-section tube structure) through the feeding port at the front end, and continuously push the material forward to the leaching tube through a set of spiral structures in the leaching tube. The slag is discharged from the slag outlet of the extraction tube, and 14 times the amount of 95°C hot water is continuously added to the end of each level of extraction tube for continuous countercurrent extraction for 1 hour. The hot water and the material flow in reverse to the front end of each level of extraction tube. Extracting solution, discharge after extruding and reclaiming part of the medicinal liquid of the peach kernel dregs, the part of the medicinal liquid reco...

Embodiment 2

[0050] A preparation method for the formula granules of peach kernels, comprising the steps of:

[0051] a, the peach kernel decoction pieces are broken into 0.5cm coarse particles;

[0052] b. Continuously input the coarse particles into the leaching tube of the spiral continuous countercurrent extractor (two-stage 10-section tube structure) through the feeding port at the front end, and continuously push the material forward to the leaching tube through a set of spiral structures in the leaching tube. The slag is discharged from the slag outlet of the extraction tube, and 14 times the amount of 95°C hot water is continuously added to the end of each level of extraction tube for continuous countercurrent extraction for 1 hour. The hot water and the material flow in reverse to the front end of each level of extraction tube. Extracting solution, discharge after extruding and reclaiming part of the medicinal liquid of the peach kernel dregs, the part of the medicinal liquid reco...

Embodiment 3

[0057] A preparation method for the formula granules of peach kernels, comprising the steps of:

[0058] a, the peach kernel decoction pieces are broken into 0.5cm coarse particles;

[0059] b. Continuously input the coarse particles into the leaching tube of the spiral continuous countercurrent extractor (two-stage 10-section tube structure) through the feeding port at the front end, and continuously push the material forward to the leaching tube through a set of spiral structures in the leaching tube. The slag is discharged from the slag outlet of the extraction tube, and 14 times the amount of 95°C hot water is continuously added to the end of each level of extraction tube for continuous countercurrent extraction for 1 hour. The hot water and the material flow in reverse to the front end of each level of extraction tube. For extracting solution, the dregs of the peach kernels are discharged; the input speed of the coarse particles of the peach kernels is 100kg / h, and the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com