Preparation method of porous graphene oxide/CaO/glucose composite adsorbent

A compound adsorption and glucose technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, alkali metal compounds, etc., can solve the problems of difficult recovery and poor repeatability, and achieve good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

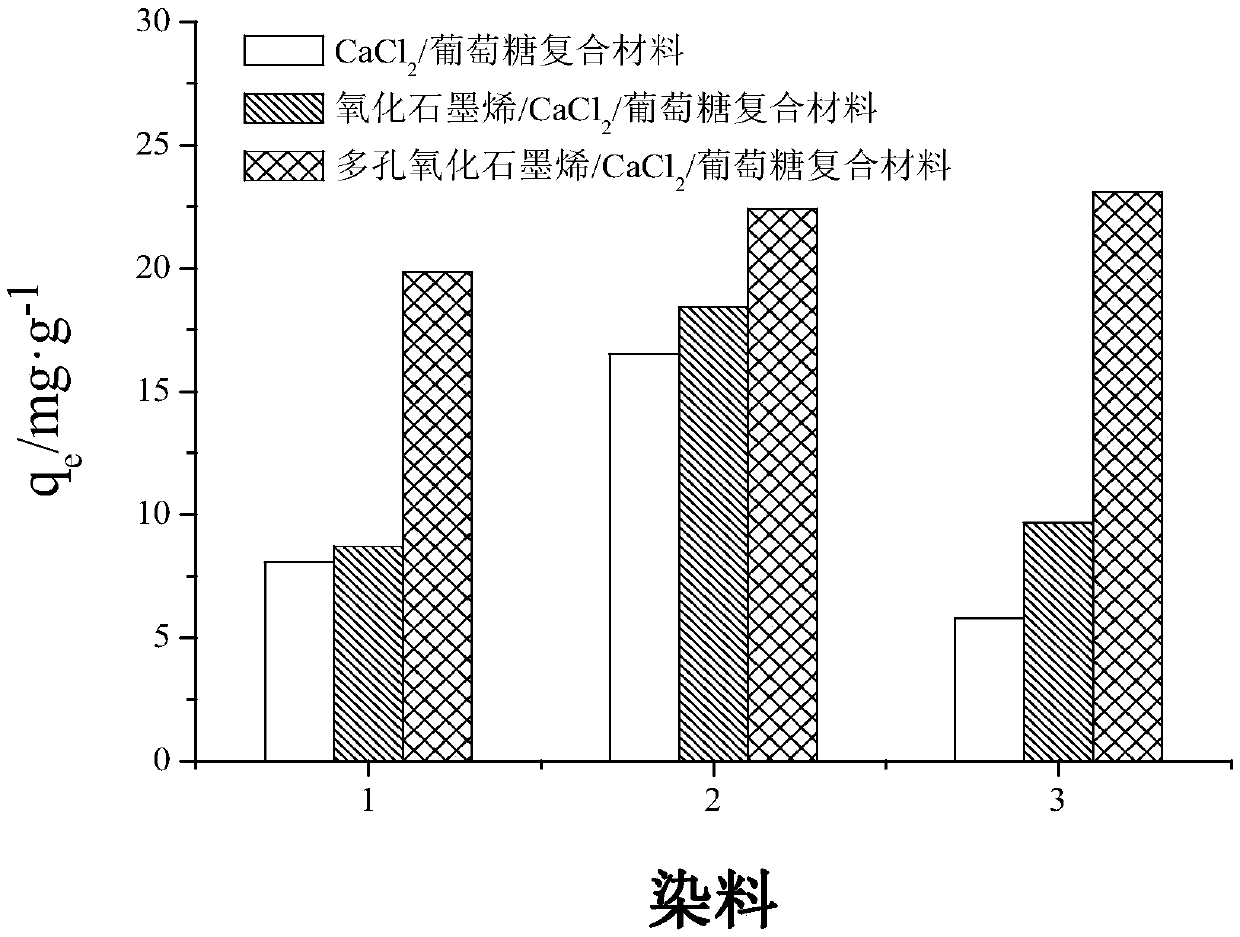

[0026] (1) Comparison of dye adsorption properties

[0027] Accurately weigh 0.2500g of methylene blue, acridine orange and orange IV samples respectively, dissolve and dilute to a 250mL volumetric flask to prepare 1g L -1 dye solution.

[0028] Weigh several parts of 0.0100g porous graphene oxide composite material, graphene oxide composite material and composite material without graphite oxide, and add the three weighed samples into the above-mentioned 25.00mL 40mg·mL -1 in the colorimetric tube containing the dye solution. After 24 hours of adsorption, measure the absorbance of the solution at the maximum absorption wavelength of each dye. The maximum absorption wavelengths of several dyes are: methylene blue: λ=660nm, acridine orange: λ=488nm, orange IV: λ=443nm, according to the standard The concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com