Method for repairing polycyclic aromatic hydrocarbon contaminated soil by chemical oxidation

A technology for polluted soil and polycyclic aromatic hydrocarbons, applied in the field of soil remediation, can solve problems such as unsatisfactory oxidation effect, difficulty in achieving remediation goals, and large consumption of oxidants, and achieve low treatment costs, reduced remediation treatment costs, and improved physical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]Get 1000g of actual PAH-contaminated soil and put it into a small stainless steel bucket, wherein the main components of PAH pollutants in the PAH-contaminated soil of the present embodiment are benzo(a)pyrene, dibenzo[a,h ] anthracene, indene benzene (1,2,3-cd) pyrene, benzo [b] fluoranthene, which are high ring pollutants with ring number ≥ 5; add 60g soda lime solid (i.e. polluted 6% of the soil mass), stirred for 10 min; then, added 50 mL of dioctyl sodium sulfosuccinate solution with a mass percentage concentration of 2%, stirred for 10 min; then added 60 g of sodium persulfate solid, stirred for 10 min; finally added 100 mL Tap water, stirred for 10 minutes, the liquid-solid ratio was 1.5:10; placed at 50°C for 15 days. The concentration of PAHs before and after the treatment of the contaminated soil was measured, and the results are shown in Table 1.

[0034] Table 1:

[0035] Pollutants

[0036] Note: ND means not detected.

Embodiment 2

[0038] Get 1000g of actual PAH-contaminated soil and put it into a small stainless steel bucket, wherein the main components of PAH pollutants in the PAH-contaminated soil of the present embodiment are benzo(a)anthracene, naphthalene and benzo[k] Fluoranthene, which is a low-ring pollutant with a ring number≤5; add 20g quicklime solid (i.e. 2% of the polluted soil quality) to the polluted soil, stir for 15min; then, add 150mL mass percent concentration of 0.2% coconut Oleylamine polyoxyethylene ether solution, stirred for 15 minutes; then added 20 g of potassium persulfate solid, stirred for 15 minutes; finally added 150 mL of tap water, stirred for 10 minutes, the liquid-solid ratio was 3:10. Place at 5°C for 5 days. The concentration of PAHs before and after the treatment of the contaminated soil was measured, and the results are shown in Table 2.

[0039] Table 2:

[0040] Pollutants

[0041] Note: ND means not detected.

Embodiment 3

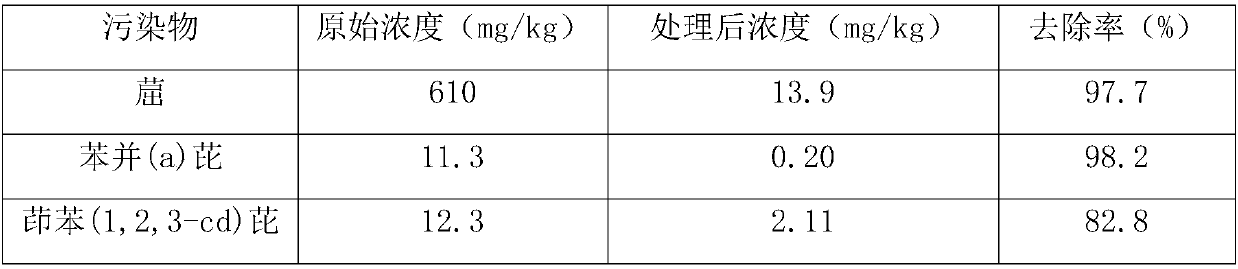

[0043] Get 1000g of actual PAH-contaminated soil and put it into a small stainless steel bucket, wherein the main components of PAH pollutants in the PAH-contaminated soil of the present embodiment are Benzo(a)pyrene and indenophenyl(1,2,3-cd)pyrene, which are a mixture of high-ring and low-ring pollutants; 40 g of quicklime solids (i.e. 4% of the mass of the contaminated soil) were added to this contaminated soil , stirred for 15 min; then, added 50 mL of a mixed solution of disodium stearyl sulfosuccinamic acid, polyethylene glycol and stearylamine polyoxyethylene ether with a concentration of 0.1% by mass, and stirred for 15 min; then added 40 g of ammonium persulfate solid, stir for 15min; finally add 50mL tap water, stir for 10min, the liquid-solid ratio is 1:10. Place at 25°C for 7 days. The concentration of PAHs before and after the treatment of the contaminated soil was measured, and the results are shown in Table 3.

[0044] table 3:

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com