Preparation method of nanosilver composite carbon nanotubes

A technology of carbon nanotubes and composite carbon, applied in the direction of carbon nanotubes, nanocarbons, nanotechnology, etc., can solve the problems of complicated and time-consuming process, high cost of wastewater pollution treatment, difficult product quality control, etc., and achieve the effect of rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

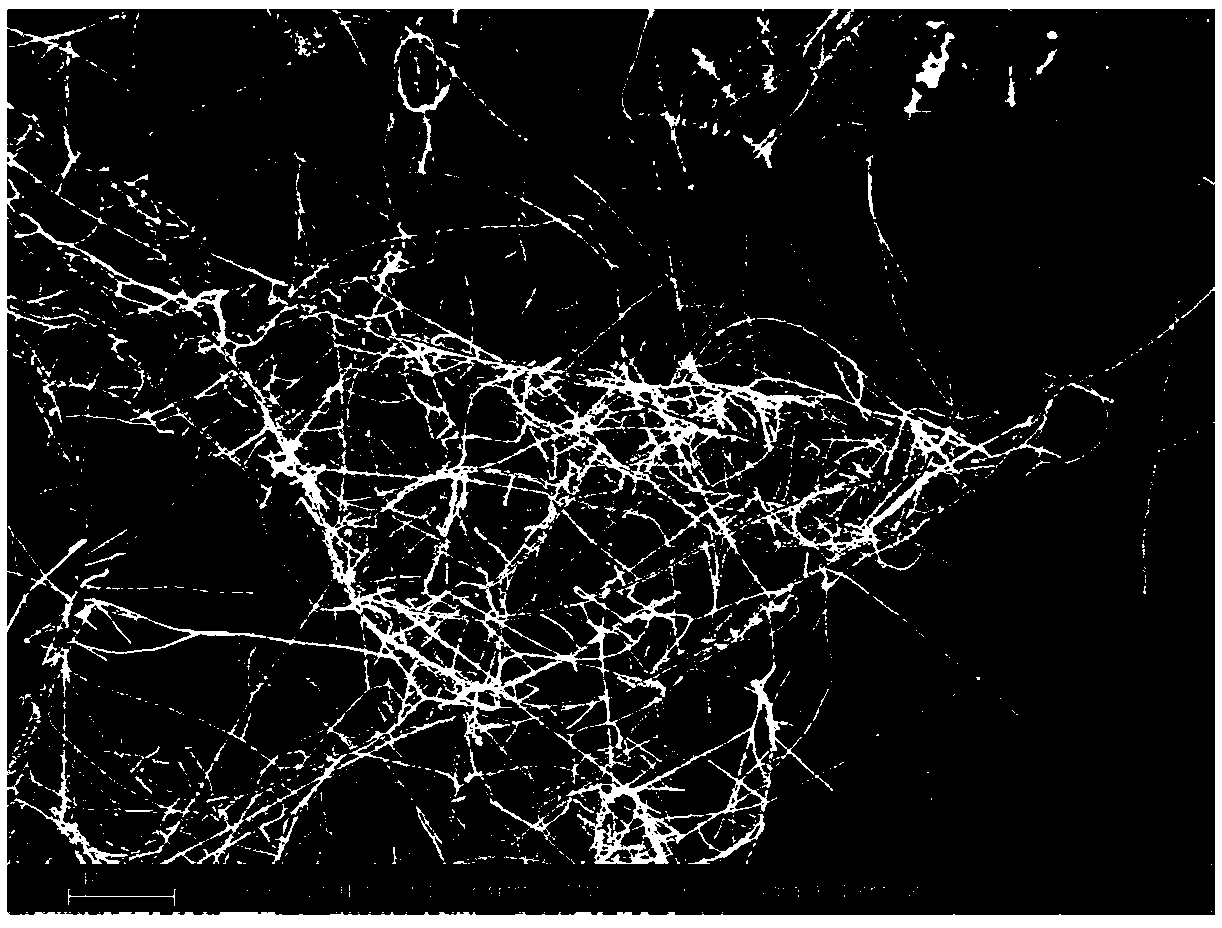

[0032] S 1 2kg of silver acetate is dissolved in 20L of water, then 144g of whisker-shaped multi-walled carbon nanotubes (Suzhou First Element Nanotechnology Co., Ltd., long 5-10 μm, diameter 50-90nm, purity greater than 99%) are added to the silver acetate aqueous solution ,Such as figure 1 shown); under the action of ultrasound, the carbon nanotubes and the silver acetate aqueous solution are mixed evenly to form the silver acetate-carbon nanotube composite slurry; then the silver acetate-carbon nanotube composite slurry is vacuum-dried at 80°C to obtain Silver acetate-carbon nanotube composite dry powder;

[0033] S 2 , compact the silver acetate-carbon nanotube composite dry powder, and then connect it with a pair of graphite electrodes; then evacuate and pass argon, repeat the operation 3 times, completely remove the air, and then evacuate to make the silver acetate-carbon nanotube composite The dry powder is unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap