A chemical waste liquid treatment device

A technology for waste liquid treatment and chemical industry, which is applied in water treatment parameter control, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc. Achieving good filtering effect, accelerating sedimentation speed and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

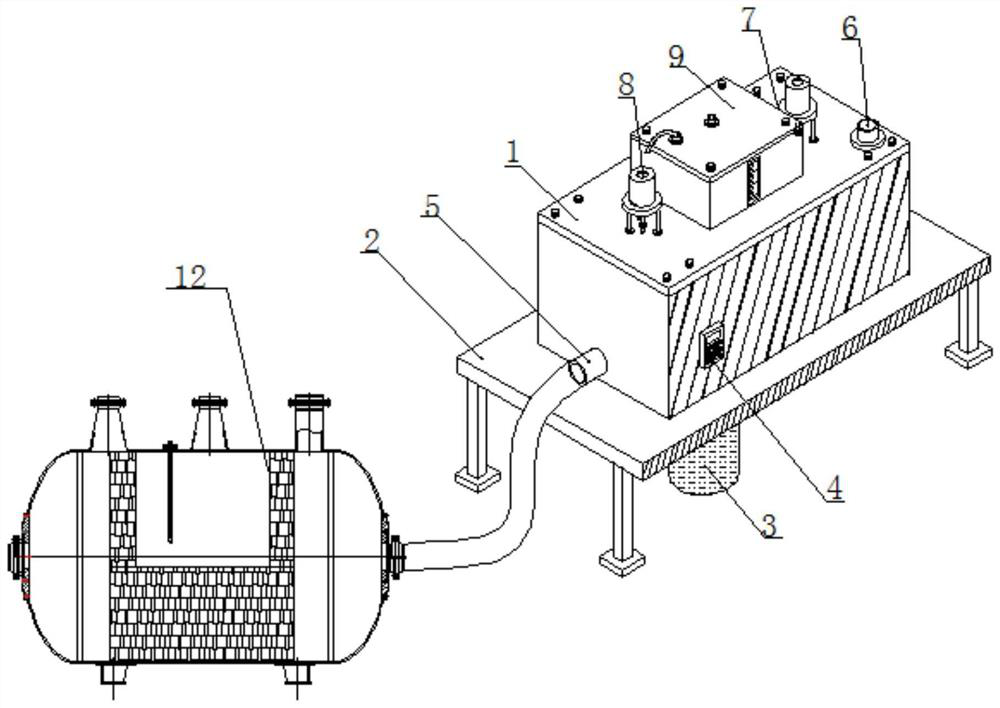

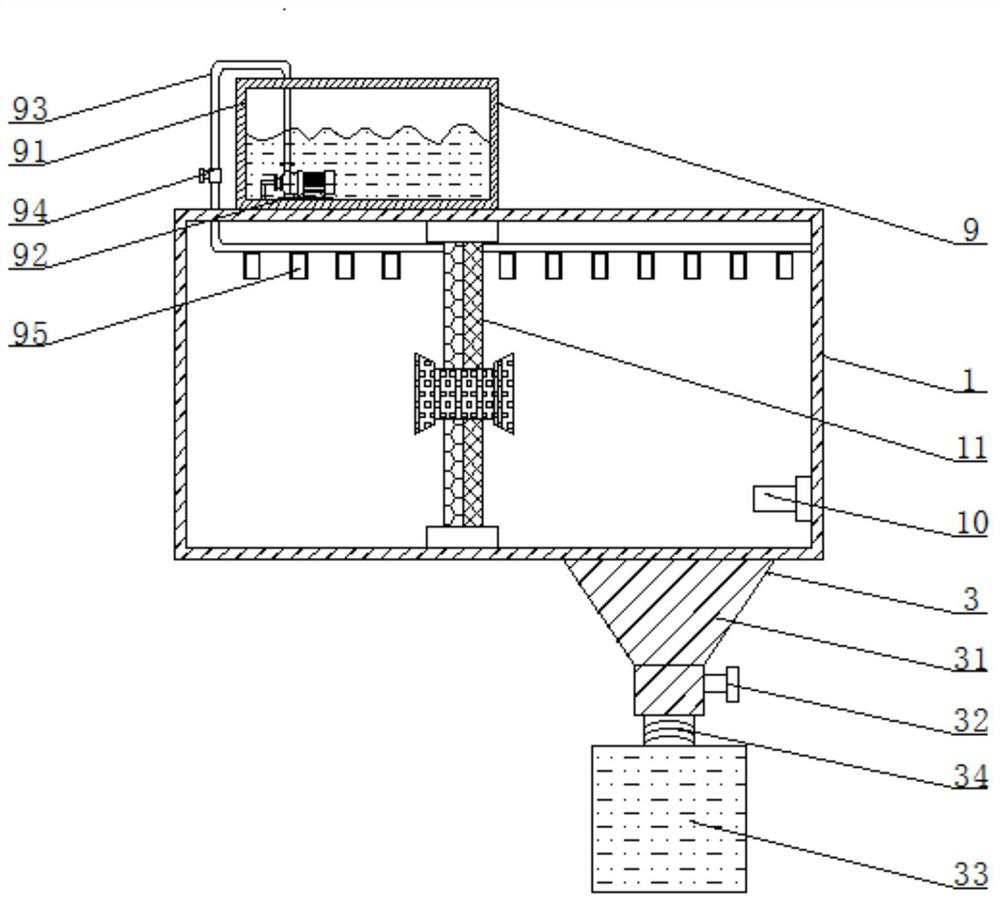

[0035] See Figure 1 ~ 7 , For example, a chemical waste liquid treatment apparatus according to the present invention, the housing 1 comprises a processing tank 12 and the secondary treatment, wherein the primary treatment tank 1 is provided on the water inlet 6, the primary treatment the outlet box is a corrosion resistant pipe 5 is connected to the secondary treatment tank 12, wherein,

[0036] The inner housing 1 is provided a process with a diaphragm seat 11, the diaphragm seat 11 to process an internal cavity of the housing 1 is divided into mutually spaced PH regulator chamber and flocculation chamber;

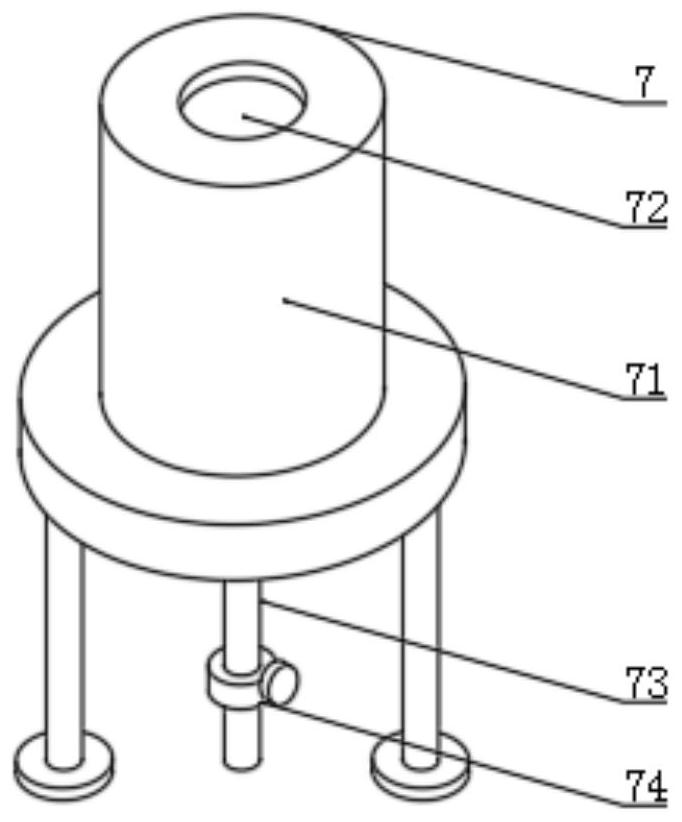

[0037]The primary treatment is provided with a cavity extending into the PH PH regulator adjustment assembly 7 of the casing 1, a process is provided on the housing 1 extends into said flocculation chamber assembly 8 flocculant is added;

[0038] The control valve is provided with a guide 16 on the guide 16 through the control valve 11 controlled by the controller on the sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com