Method for improving sludge dewatering performance through ozone/coagulant/hydrophobic polyurethane

A sludge dewatering and coagulant technology, applied in water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, sludge treatment, etc., can solve the problem of insignificant sludge dewatering effect and sludge EPS structure Problems such as poor destruction effect, to achieve the effect of improving oxidation efficiency, wide application range and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

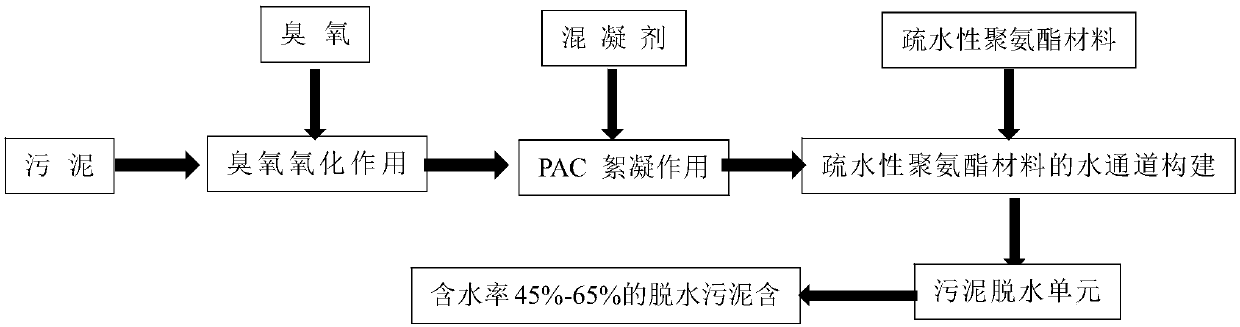

Embodiment 1

[0032] The sludge to be dewatered in this implementation example is collected from a domestic sewage treatment plant in Minhang District, Shanghai. The sewage treatment plant uses A 2 The O process treats municipal sewage, and the treatment process is as follows: figure 1 shown. The dewatered sludge is collected in the secondary sedimentation tank. After the sludge was retrieved, it was settled by gravity for 8 hours and passed through 10 mesh and 50 mesh screens. The moisture content of the sludge was 99.5%. Introduce ozone with a concentration of 30mg / g dry sludge into the sludge in the form of microbubbles, react for 30min, and decompose sludge flocs and cells; then add 0.25g / g dry sludge PAC to the sludge, Stir at a speed of 300r / min for 1min, then stir at a speed of 60r / min for 5min to promote the reconstruction of sludge flocs and the release of bound water; add hydrophobic polyurethane materials with a particle size of 2cm to the treated sludge In the solution, the v...

Embodiment 2

[0034] The sludge to be dewatered in this implementation example is collected from a domestic sewage treatment plant in Minhang District, Shanghai. The sewage treatment plant uses A 2The O process treats municipal sewage. The dewatered sludge is collected in the secondary sedimentation tank. After the sludge was retrieved, it was settled by gravity for 8 hours and passed through 10-mesh and 50-mesh sieves. The moisture content of the sludge was 98.5%. Introduce ozone with a concentration of 60mg / g dry sludge into the sludge in the form of microbubbles, react for 60min, and decompose sludge flocs and cells; then add 0.15g / g PAC of dry sludge to the sludge, Stir at a speed of 200r / min for 3 minutes, then stir at a speed of 20r / min for 8 minutes to promote the reconstruction of sludge flocs and the release of bound water; add hydrophobic polyurethane materials with a particle size of 1cm to the treated sludge In the solution, the volume ratio is 35%. After mixing evenly, transf...

Embodiment 3

[0036] The sludge to be dewatered in this implementation example is collected from a domestic sewage treatment plant in Minhang District, Shanghai. The sewage treatment plant uses A 2 The O process treats municipal sewage. The dewatered sludge is collected in the secondary sedimentation tank. After the sludge was taken back, it was settled by gravity for 8 hours, and passed through 10 mesh and 50 mesh screens. The moisture content of the sludge was 99.3%. Introduce ozone with a concentration of 40 mg / g dry sludge into the sludge in the form of microbubbles, react for 35 minutes, and decompose sludge flocs and cells; then add 0.2 g / g dry sludge PAC to the sludge, Stir at a speed of 250r / min for 2min, and then stir at a speed of 40r / min for 6min to promote the reconstruction of sludge flocs and the release of bound water; add hydrophobic polyurethane materials with a particle size of 0.5cm to the treated sewage In the mud solution, the volume ratio is 30%. After mixing evenly,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com