Ceramic with good weatherability and preparation method of ceramic

A technology of weather resistance and ceramics, applied in the field of ceramics with good weather resistance and its preparation, can solve the problems of ceramic surface yellowing, affecting the appearance of ceramics, ceramic aging, etc., achieve fine texture, good adsorption effect, improve corrosion resistance and resistance abrasive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

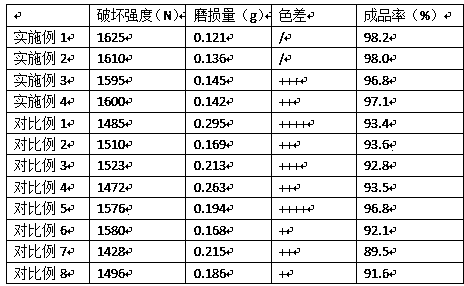

Examples

Embodiment 1

[0032] A method for preparing ceramics with good weather resistance, comprising the following steps:

[0033] (1) Grind quartz stone and mica powder, pass through a 180-mesh sieve, mix with modified fly ash and bentonite, continue crushing, and pass through a 200-mesh sieve;

[0034] (2), mixing the mixture obtained in step (1) with diatomaceous earth, glass fiber, and nano-zinc oxide, ball milling, and passing through a 200-mesh sieve to obtain ceramic materials;

[0035] (3) Mix the ceramic materials obtained in step (2) with the mixed solution in a ratio of 10:1 by weight, disperse with a disperser, press and mold, and dry in the shade to obtain a green body; the mixed solution is polyethylene It is made by mixing alcohol and water at a weight ratio of 1:10;

[0036] (4) Heat the green body at 85-88°C and moisture content 85-90% for 36 hours, then raise the temperature to 595-605°C at 22-25°C / min, keep it warm for 30-45s, and heat it for 18-20 ℃ / min to raise the temperatu...

Embodiment 2

[0053] A method for preparing ceramics with good weather resistance, comprising the following steps:

[0054] (1) Grind quartz stone and mica powder, pass through a 180-mesh sieve, mix with modified fly ash and bentonite, continue crushing, and pass through a 200-mesh sieve;

[0055] (2), mixing the mixture obtained in step (1) with diatomaceous earth, glass fiber, and nano-zinc oxide, ball milling, and passing through a 200-mesh sieve to obtain ceramic materials;

[0056] (3) Mix the ceramic material obtained in step (2) with the mixed solution in a ratio of 12:1 by weight, disperse with a disperser, press and mold, and dry in the shade to obtain a green body; the mixed solution is polyethylene It is made by mixing alcohol and water at a weight ratio of 1:10;

[0057] (4) Heat the green body at 86°C and moisture content of 90% for 48 hours, then raise the temperature to 585°C at 22°C / min, hold for 35s, raise the temperature to 1410°C at 17°C / min, and hold for 65min, naturall...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap