Preparation method of thiamine 1,4-naphthoquinone compound

A technology of a compound, naphthoquinone, applied in the field of preparation of thiamined 1,4-naphthoquinone compound, can solve problems such as inability to realize one-step reaction, poor reaction adaptability, etc., and achieve mild, simple and economical reaction conditions good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

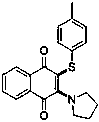

Embodiment 1

[0024] The preparation method of thiamined 1,4-naphthoquinone compound, the steps are as follows:

[0025] In a 25 mL reaction tube, cuprous iodide (20 mol%), 0.5 mmol of 1,4-naphthoquinone, 2 mL of solvent DMF, 0.5 mmol of p-methylbenzenethiol, and 1.75 mmol of tetrahydropyrrole were added, and the mixture was stirred in an oxygen atmosphere. , the reaction temperature was controlled to be 100 °C, and after 10 hours of reaction, silica gel column chromatography was used to separate the final product, and the yield of the final product was 80% based on the molar weight of 1,4-naphthoquinone as 100%.

[0026] The specific results are as follows:

[0027]

[0028] 1 H NMR (400 MHz, Chloroform- d ) δ 8.10 (dd, J = 7.7, 1.3 Hz, 1H), 7.93(dd, J = 7.7, 1.3 Hz, 1H), 7.69 (td, J = 7.5, 1.4 Hz, 1H), 7.60 (td, J = 7.5,1.3 Hz, 1H), 7.05 (q, J = 8.3 Hz, 5H), 3.94 – 3.85 (m, 4H), 2.28 (s, 3H), 1.85 – 1.77 (m, 4H). 13 C NMR (101 MHz, Chloroform- d ) δ 184.38, 180.28, 155.6...

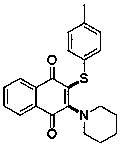

Embodiment 2

[0030] The preparation method of thiamined 1,4-naphthoquinone compound, the steps are as follows:

[0031] In a 25 mL reaction tube, cuprous iodide (20 mol%), 0.5 mmol of 1,4-naphthoquinone, 2 mL of solvent DMF, 0.5 mmol of p-ethylbenzenethiol, 1.75 mmol of tetrahydropyrrole were added, and the mixture was stirred in an oxygen atmosphere. The reaction temperature was controlled to be 100 °C, and after 10 hours of reaction, the final product was obtained by separation by silica gel column chromatography, and the yield of the final product was 65% based on the molar amount of 1,4-naphthoquinone being 100%.

[0032] The specific results are as follows:

[0033]

[0034] 1 H NMR (400 MHz, Chloroform- d ) δ 8.11 (dd, J = 7.7, 1.3 Hz, 1H), 7.94(dd, J = 7.6, 1.3 Hz, 1H), 7.70 (td, J = 7.5, 1.4 Hz, 1H), 7.61 (td, J = 7.5,1.3 Hz, 1H), 7.13 – 7.04 (m, 4H), 3.97 – 3.85 (m, 4H), 2.58 (q, J = 7.6 Hz, 2H), 1.87 – 1.75 (m, 4H), 1.20 (t, J = 7.6 Hz, 3H). 13 C NMR (101 MHz, ...

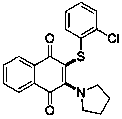

Embodiment 3

[0036] The preparation method of thiamined 1,4-naphthoquinone compound, the steps are as follows:

[0037] In a 25 mL reaction tube, add cuprous iodide (20 mol%), 0.5 mmol of 1,4-naphthoquinone, 2 mL of solvent DMF, 0.5 mmol of 2-chlorobenzenethiol, 1.75 mmol of tetrahydropyrrole, and stir in an oxygen atmosphere. , the reaction temperature was controlled to be 100°C, and after 10 hours of reaction, the final product was obtained by silica gel column chromatography separation, and the yield of the final product was 65% based on the molar amount of 1,4-naphthoquinone being 100%.

[0038] The specific results are as follows:

[0039]

[0040] 1 H NMR (400 MHz, Chloroform- d ) δ 8.09 (dd, J = 7.8, 1.2 Hz, 1H), 7.93(dd, J = 7.6, 1.3 Hz, 1H), 7.69 (td, J = 7.6, 1.4 Hz, 1H), 7.61 (td, J = 7.6,1.4 Hz, 1H), 7.30 (dd, J = 7.8, 1.4 Hz, 1H), 7.09 (td, J = 7.6, 1.5 Hz, 1H), 7.01 (td, J = 7.6, 1.7 Hz, 1H), 6.93 (dd, J = 7.8, 1.6 Hz, 1H), 3.96 – 3.87(m, 4H), 1.90 – 1.79...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com