Polysiloxane polyether polyurethane elastomer with high mechanical property and preparation method of elastomer

A technology of polysiloxane polyether and polyurethane elastomer, which is applied in the field of silicone modified polyurethane synthesis, can solve the problems of poor compatibility, poor mechanical properties, and unsatisfactory performance of synthetic materials, etc., and achieve high tensile strength and elongation at break, the effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

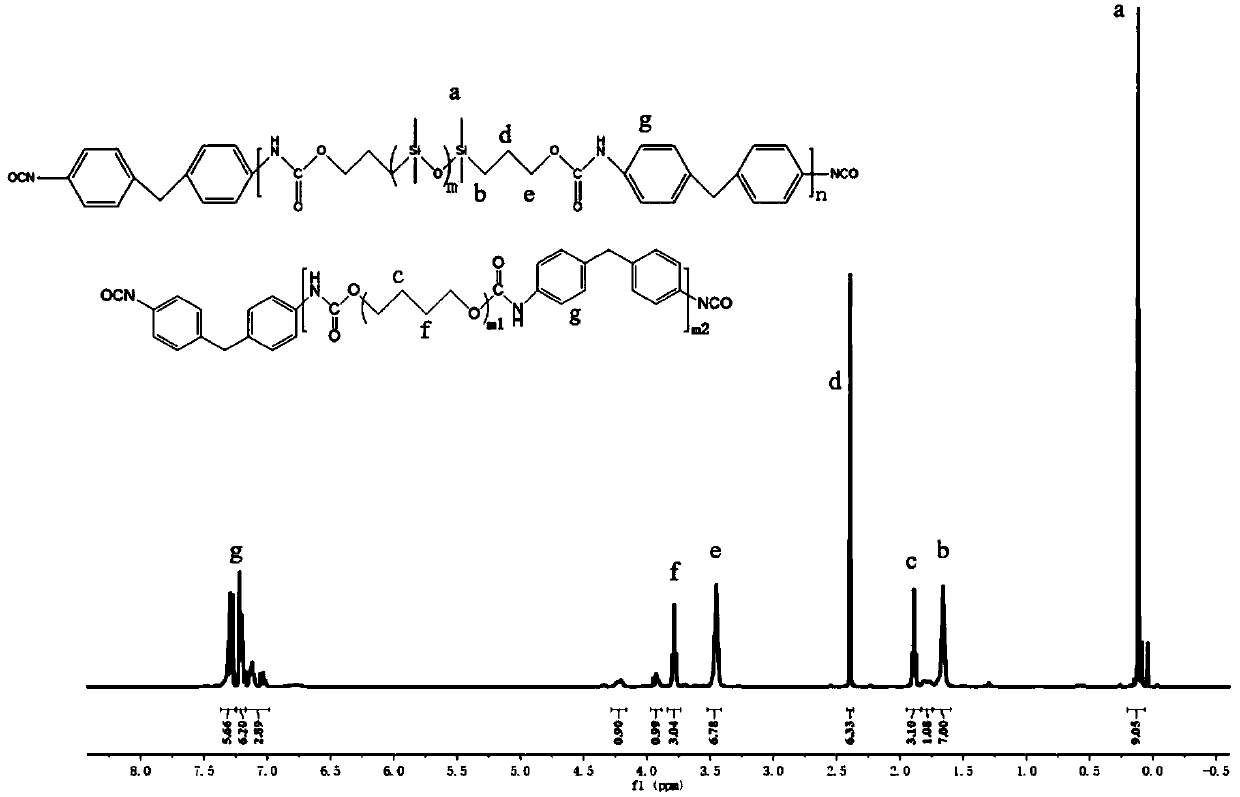

Image

Examples

Embodiment 1

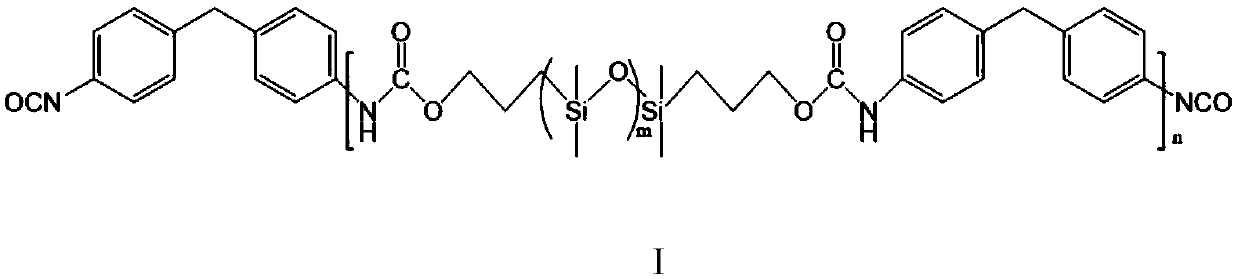

[0052] A preparation method of a polysiloxane polyether polyurethane elastomer with high mechanical properties, comprising the steps of:

[0053] In a round-bottom four-neck flask equipped with magnetic stirring, an inert gas feeding device, a thermometer and a constant pressure dropping funnel, add 0.76 g of diphenylmethane diisocyanate, and when the temperature rises to 60 ° C, under argon protection , under strong stirring (stirring rate is 300r / min), 5.04g number average molecular weight is 2000 the polysiloxane of hydroxypropyl end-capping through dropping funnel drop by drop (dropping speed rate is 3~5 drops / second ) into the above solution, after the dropwise addition, react at 85° C. for 4 h until the NCO content is stable, and prepare the isocyanate-terminated prepolymer A.

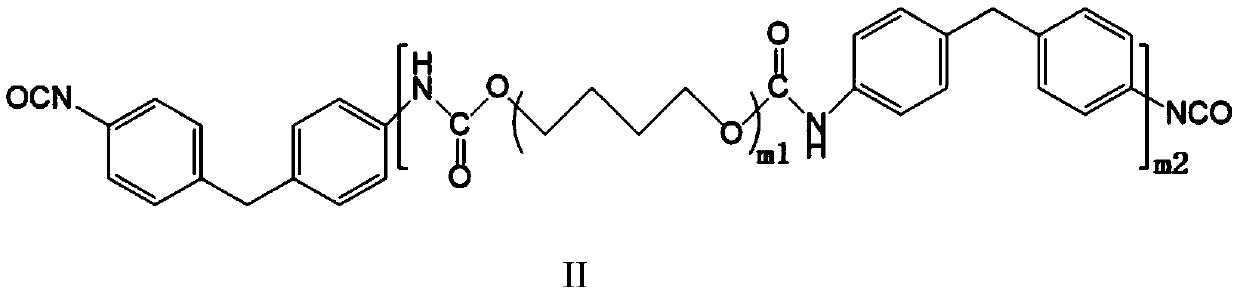

[0054] At the same time, in another round-bottomed four-neck flask equipped with magnetic stirring, inert gas feeding device, thermometer and constant pressure dropping funnel, add 6.79g of diphe...

Embodiment 2

[0058] A preparation method of a polysiloxane polyether polyurethane elastomer with high mechanical properties, comprising the steps of:

[0059] In a round-bottomed four-neck flask equipped with magnetic stirring, an inert gas feeding device, a thermometer and a constant pressure dropping funnel, add 1.39 g of diphenylmethane diisocyanate, and when the temperature rises to 60 ° C, under argon protection , under strong stirring (stirring rate is 300r / min), 8.02g number average molecular weight is 2000 the polysiloxane of hydroxypropyl end-capping through dropping funnel drop by drop (dropping speed rate is 3~5 drops / second ) into the above solution, after the dropwise addition, react at 85° C. for 4 h until the NCO content is stable, and prepare the isocyanate-terminated prepolymer A.

[0060] At the same time, in another round-bottomed four-neck flask equipped with magnetic stirring, inert gas feeding device, thermometer and constant pressure dropping funnel, add 5.52 g of di...

Embodiment 3

[0063] A preparation method of a polysiloxane polyether polyurethane elastomer with high mechanical properties, comprising the steps of:

[0064] In a round-bottomed four-neck flask equipped with magnetic stirring, an inert gas feeding device, a thermometer and a constant pressure dropping funnel, add 1.97 g of diphenylmethane diisocyanate, and when the temperature rises to 60 ° C, under the protection of argon, 1. Under strong stirring (stirring rate is 300r / min), 10.35g number-average molecular weight is 2000 hydroxypropyl end-capped polysiloxane drop by drop through dropping funnel (dropping rate is 3~5 drops / second ) into the above solution, after the dropwise addition, react at 85° C. for 4 h until the NCO content is stable, and prepare the isocyanate-terminated prepolymer A.

[0065] At the same time, in another round-bottomed four-neck flask equipped with magnetic stirring, an inert gas feeding device, a thermometer and a constant pressure dropping funnel, add 4.56 g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com