Emulsified asphalt and preparation method thereof

A technology for emulsified asphalt and bitumen, which is used in building components, building insulation materials, buildings, etc., and can solve problems such as stone mismatch, easy layering and precipitation, and insufficient stone cohesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

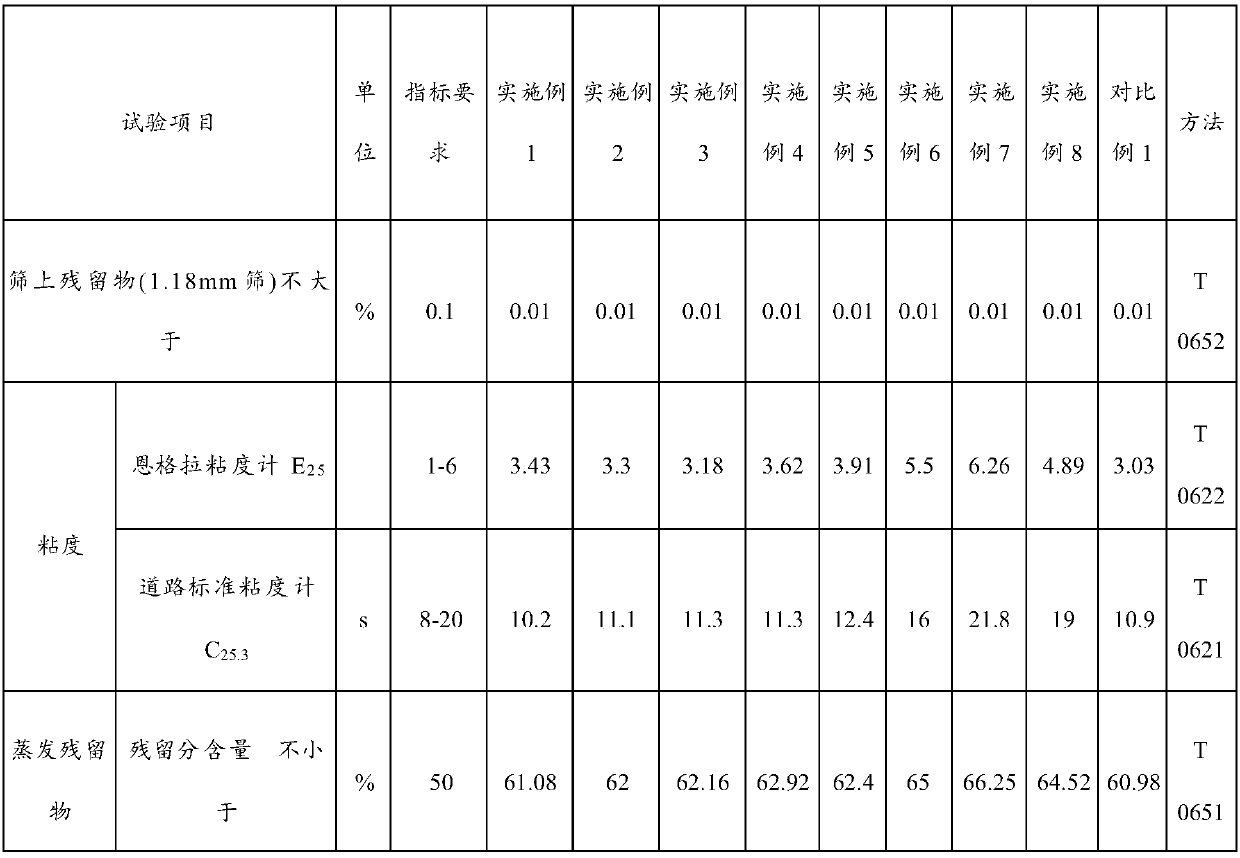

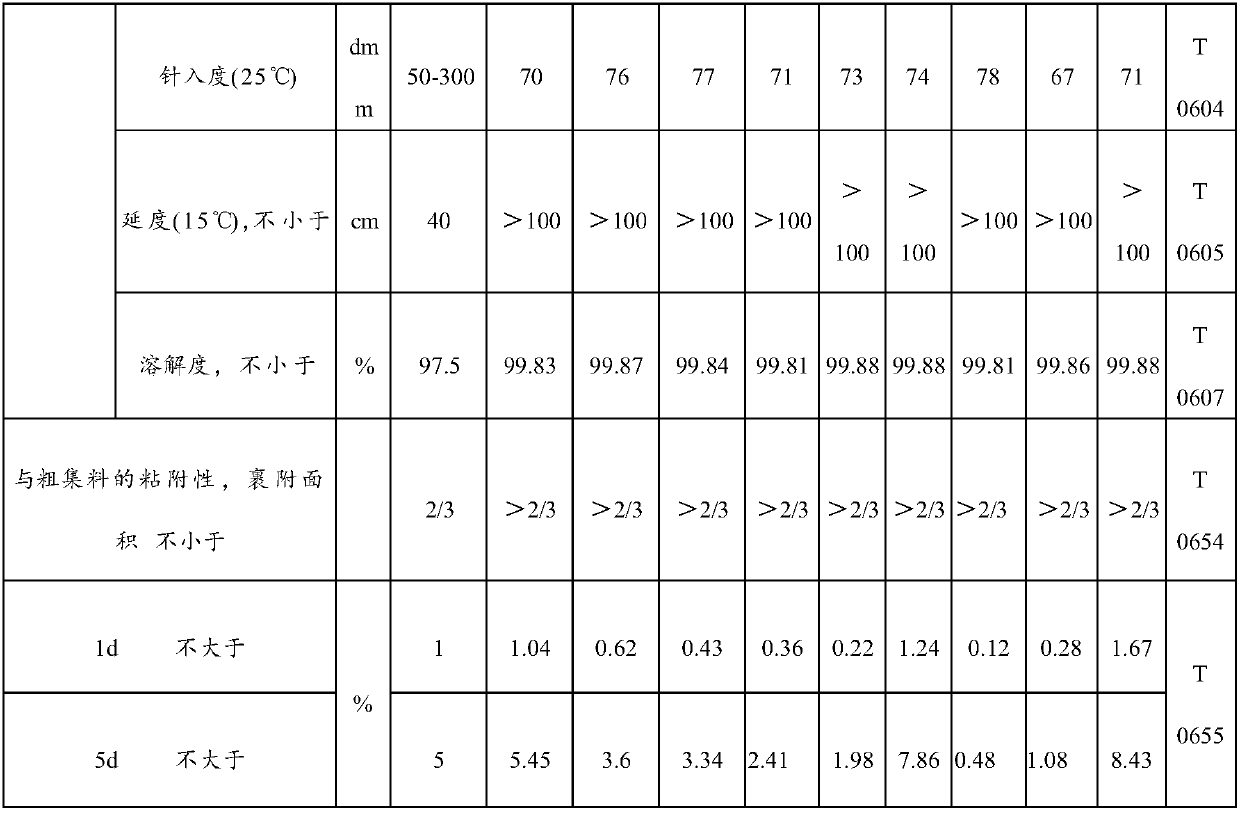

Examples

preparation example Construction

[0025] Aiming at the problem of poor stability of emulsified asphalt in the prior art, this application provides an emulsified asphalt and a preparation method thereof. The emulsified asphalt is added with a compound cationic emulsifier and a nonionic emulsifier to make the emulsified asphalt obtained have a relatively high good stability. Specifically, the emulsified asphalt is prepared from raw materials comprising the following components:

[0026] Asphalt 50wt% ~ 60wt%;

[0027] Compound emulsifier 1.5wt% ~ 4.5wt%;

[0028] remaining water;

[0029] The compound emulsifier consists of 1wt%-3wt% cationic emulsifier and 0.5wt%-1.5wt% nonionic emulsifier.

[0030] In the emulsified asphalt, the asphalt is the base material, which is the asphalt well known to those skilled in the art, and there is no particular limitation in this application. The content of the asphalt is 50wt%-60wt%; in some specific embodiments, the content of the asphalt is 52wt%-58wt%.

[0031] The co...

Embodiment 1

[0046] The emulsified asphalt is prepared from the following components by mass percentage: 60% asphalt, 2% compound emulsifier and the rest water;

[0047] Described complex emulsifier comprises 0.5% cationic emulsifier, 0.5% nonionic emulsifier; Described nonionic emulsifier is polyoxyethylene octylphenol ether (OP-10), and described cationic emulsifier The agent is a quaternary ammonium salt;

[0048] The emulsified asphalt is prepared by the following method:

[0049] Dissolve the water and compound emulsifier evenly according to the ratio, and heat to 50-60°C to obtain soap liquid; heat the asphalt to 135°C-145°C for later use;

[0050] Preheat the colloid mill, add the soap solution to the colloid mill and circulate for 1-2 minutes, add the molten asphalt to the colloid mill, and stir at a high speed for 1-2 minutes to form emulsified asphalt, wherein the asphalt is about Added within 1min.

Embodiment 2

[0052] Emulsified asphalt is prepared from the following components in mass percentage: 60% asphalt, 2.5% compound emulsifier and the rest water;

[0053] Described complex emulsifier comprises 2% cationic emulsifier, 0.5% nonionic emulsifier; Described nonionic emulsifier is polyoxyethylene octylphenol ether (OP-10), and described cationic emulsifier The agent is a quaternary ammonium salt.

[0054] The emulsified asphalt is prepared by the following method:

[0055] Dissolve the water and compound emulsifier evenly according to the ratio, and heat to 50-60°C to obtain soap liquid; heat the asphalt to 135°C-145°C for later use;

[0056] Preheat the colloid mill, add the soap solution to the colloid mill and circulate for 1-2 minutes, add the molten asphalt to the colloid mill, and stir at a high speed for 1-2 minutes to form emulsified asphalt, wherein the asphalt is about Added within 1min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com