Two-degree-of-freedom heterodyne optical grating interference measurement method and system with high tolerance

A technology of grating interference and measurement system, which is applied in the direction of interferometer, measuring device, optics, etc., can solve the problems of anti-aliasing, high-magnification optical subdivision and high angle tolerance, short distance between laser light source and optical mirror group, etc. Installation and alignment requirements are high, so as to improve measurement resolution, ensure effective coupling, and improve energy utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

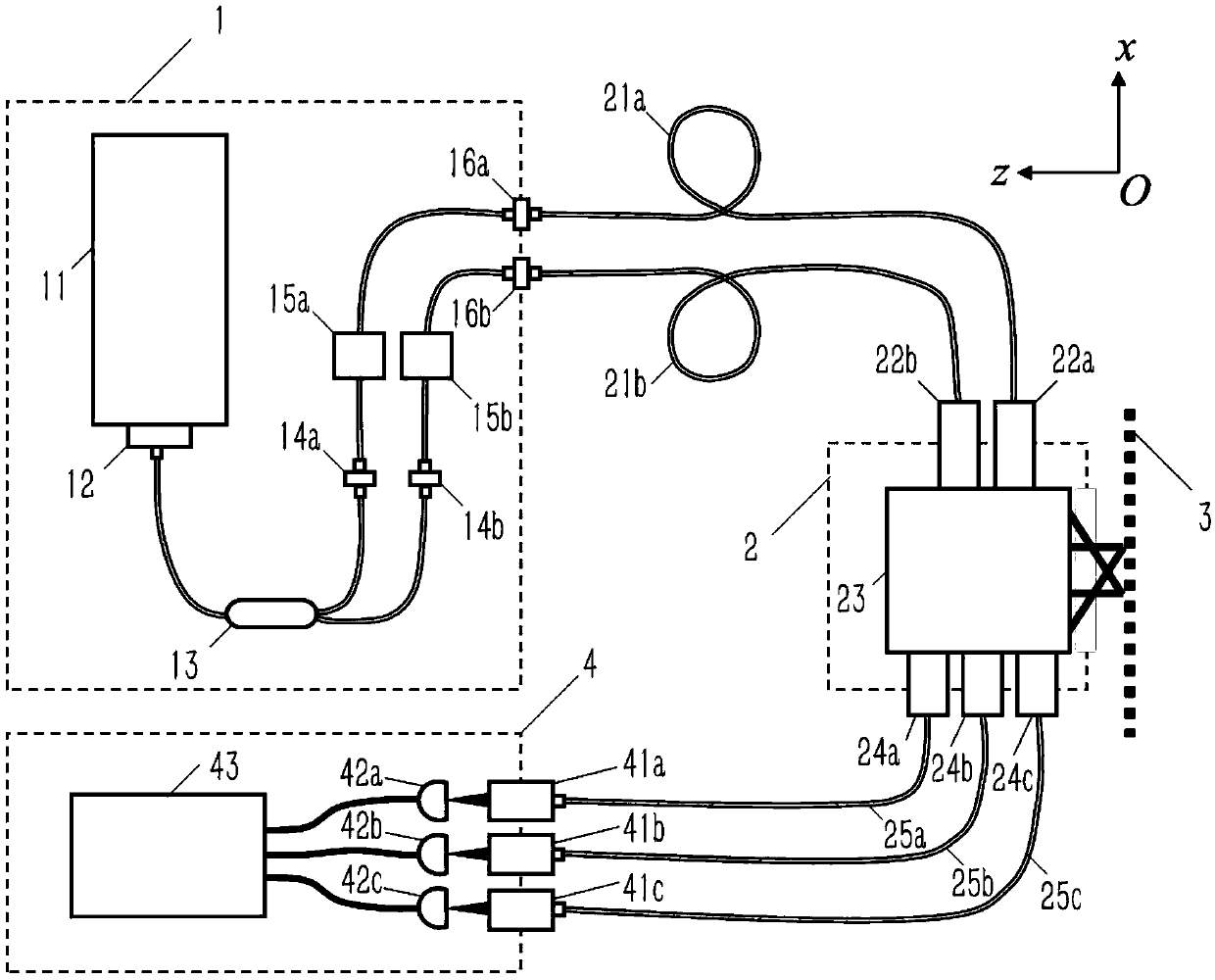

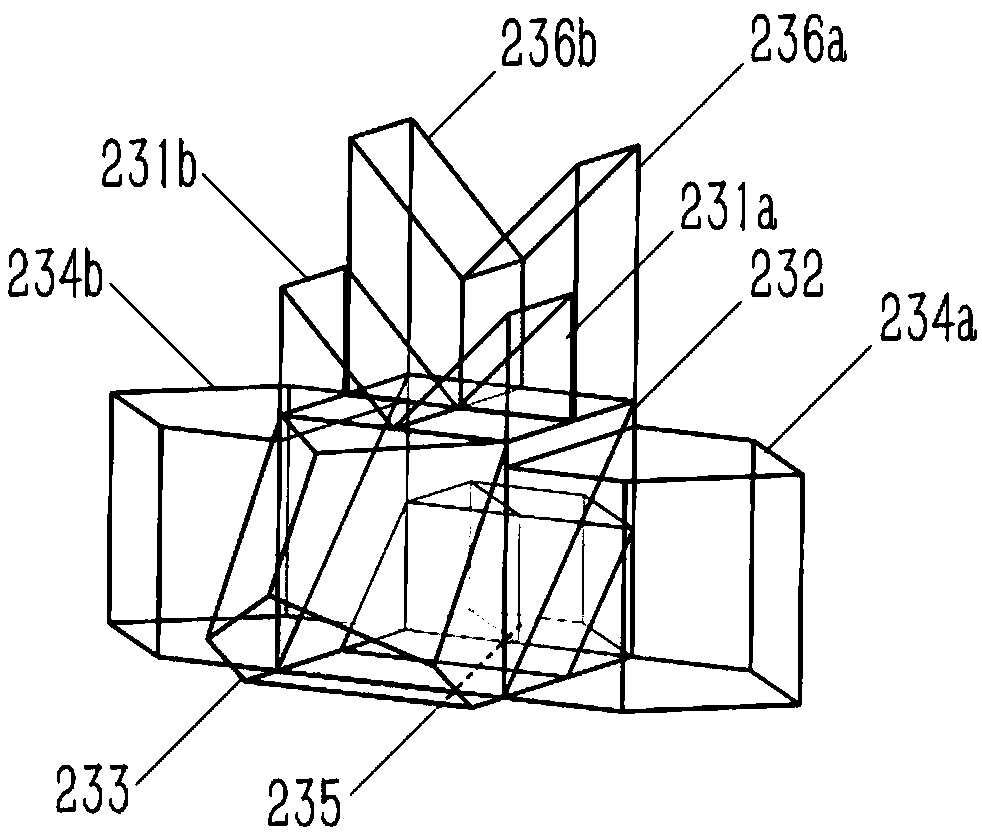

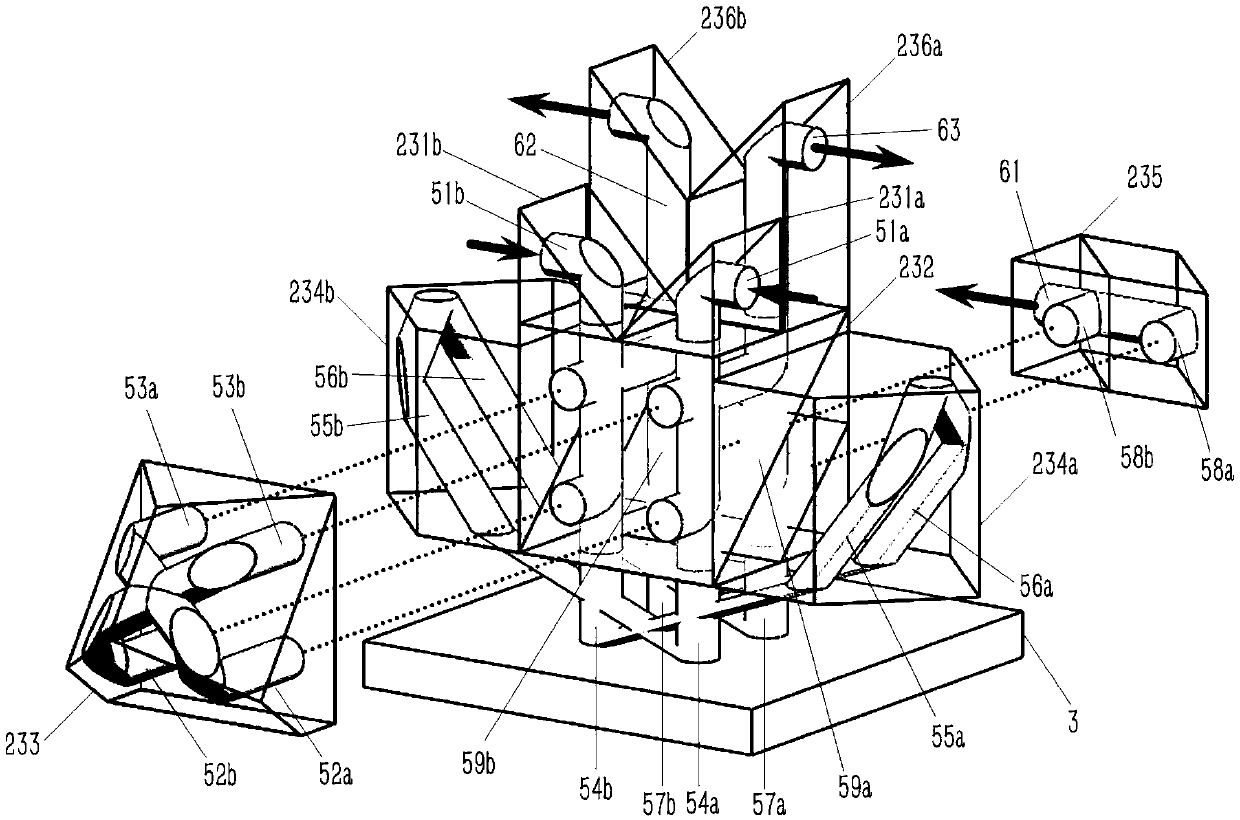

[0018] A high-tolerance two-degree-of-freedom heterodyne grating interferometry method. The heterodyne laser outputs two laser beams simultaneously, wherein the first laser beam is at the first frequency, and the second laser beam is at the second frequency, separated in space. Transmitted to the first beam splitting surface to obtain the corresponding reference beam and measurement beam, wherein the two reference beams pass through the retroreflector structure to form the first reference beam and the second reference beam, and enter the third beam splitting surface; the two measurement beams are perpendicular to the measured grating , through the secondary diffraction structure formed by the grating-retroreflector, the corresponding first measurement beam and the second measurement beam are obtained, and are divided into two parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com