A submicron flow channel microfluidic chip and its manufacturing method

A microfluidic chip and sub-micron technology, which is applied in the fields of life science and medicine, can solve problems such as the inability to determine the volume of nanopore liquid and the inability to accurately detect the concentration of the sample to be tested.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

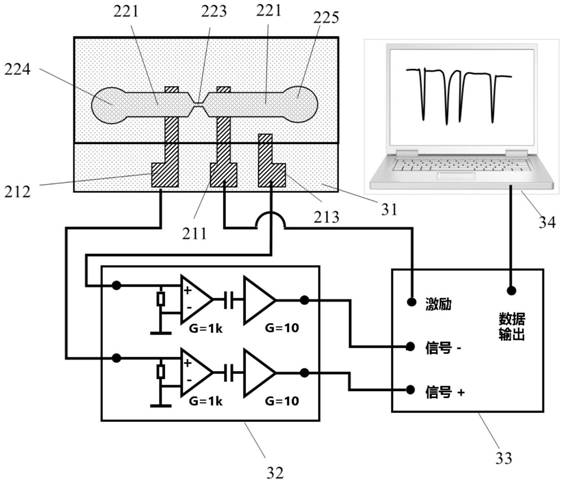

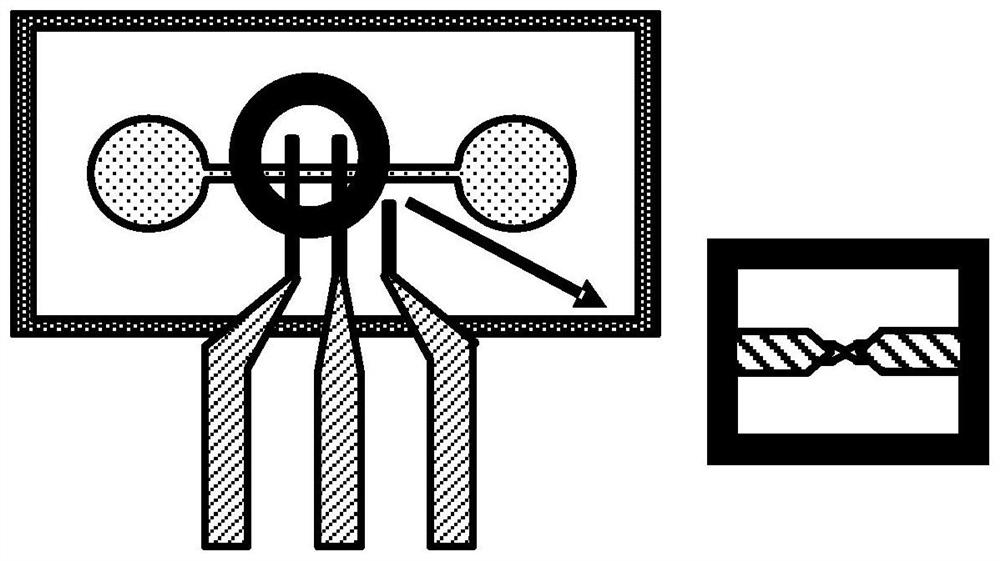

[0079] like figure 2 In (I), the application provides a submicron channel microfluidic chip, comprising:

[0080] A base layer 21, the upper surface of which is provided with an excitation electrode and a first detection electrode;

[0081] The upper substrate 22 is provided with a micro-nano channel 221 on its lower surface, and the channel width in the middle of the micro-nano channel 221 is less than 1 micron and is provided with protrusions 222; the lower surface of the upper substrate 22 and the base layer 21 Bonding on the upper surface of the upper surface, wherein the gap between the raised structure and the base layer forms a submicron flow channel 223;

[0082] Wherein, the excitation electrode 211 and the first detection electrode 212 are respectively located at both ends of the submicron channel 223 and arranged in contact with the micronano channel 221;

[0083] Wherein, the upper substrate is also provided with a reagent injection port 224 and an outlet 225 co...

Embodiment 2

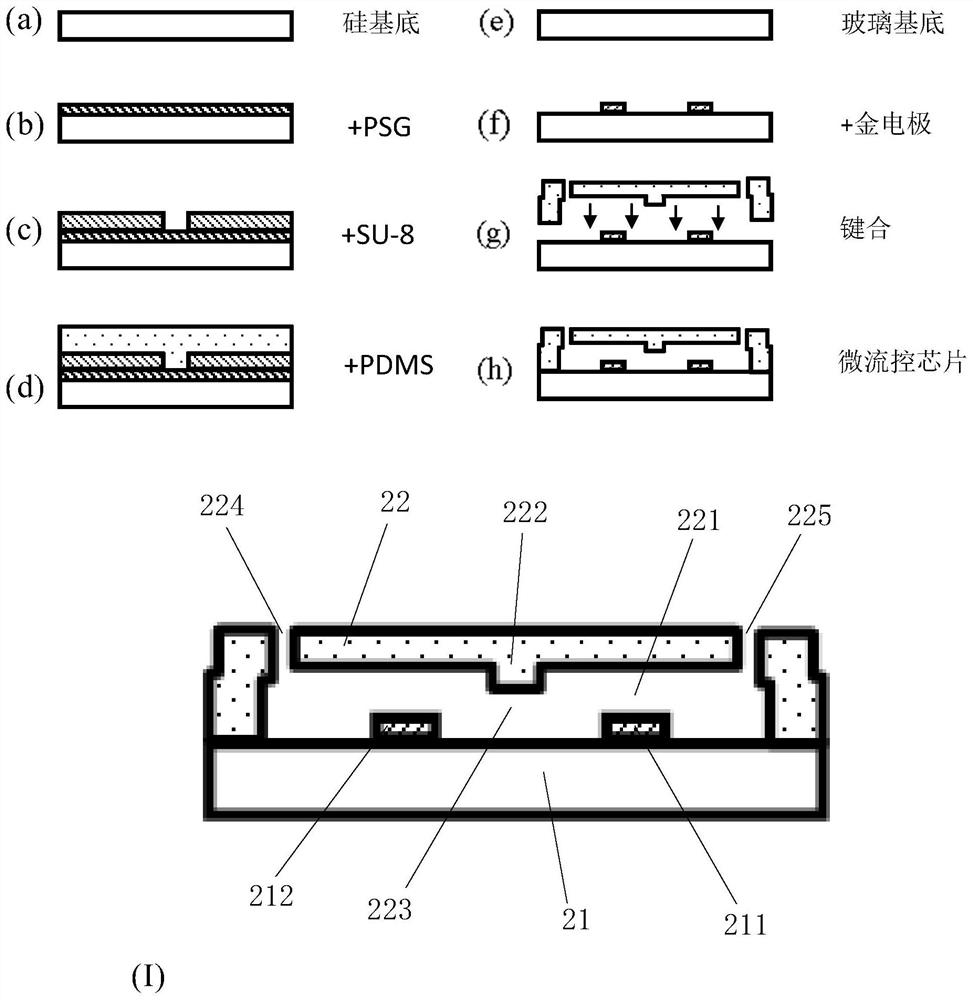

[0102] like Figure 5 As shown, based on the submicron flow channel microfluidic chip in Example 1, this embodiment also provides a method for manufacturing a submicron flow channel microfluidic chip, including steps:

[0103] S501, making an upper substrate with micro-nano channels on the lower surface; wherein, the flow channel in the middle of the micro-nano channels has a width less than 1 micron and is provided with protrusions; specifically, including:

[0104] S501.1, making a submicron flow channel template, including:

[0105] S501.1.1. Use piranha and hydrofluoric acid solution to clean the upper surface and polish a low-resistance silicon wafer to remove contamination and impurities on the surface of the silicon wafer; wherein, the piranha is a mixed solution of concentrated sulfuric acid and hydrogen peroxide , wherein the concentrated sulfuric acid: the volume ratio of hydrogen peroxide is 3:1; wherein, the low-resistance silicon chip is placed on the bottom of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com