Preparation method of PVB (Polyvinyl Butyral) resin powder with high comprehensive property

A comprehensive performance and resin powder technology, applied in the field of polyvinyl butyral production, can solve the problems of unsatisfactory PVB resin powder, etc., and achieve the effects of reducing resin agglomeration, good fluidity, and accelerated reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

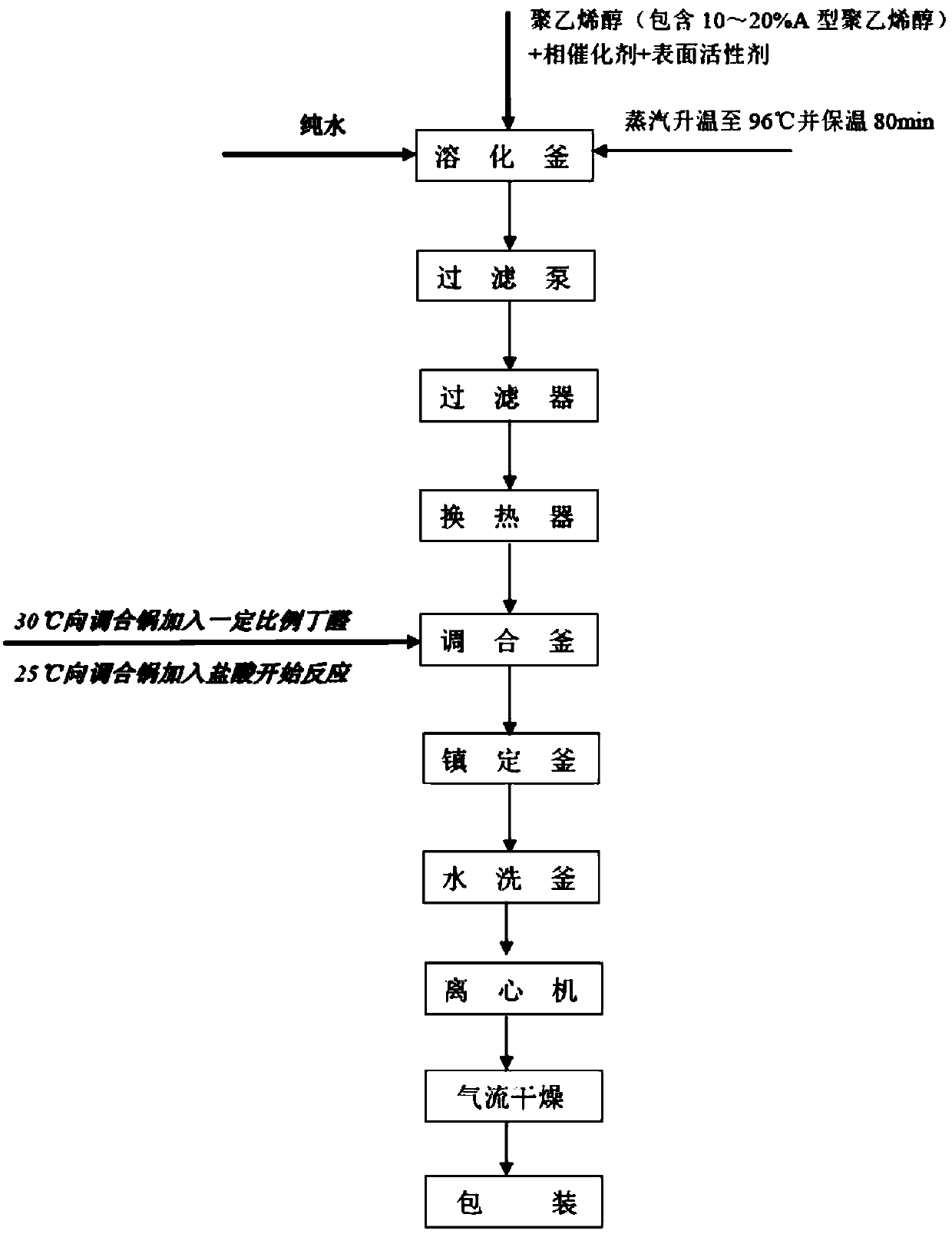

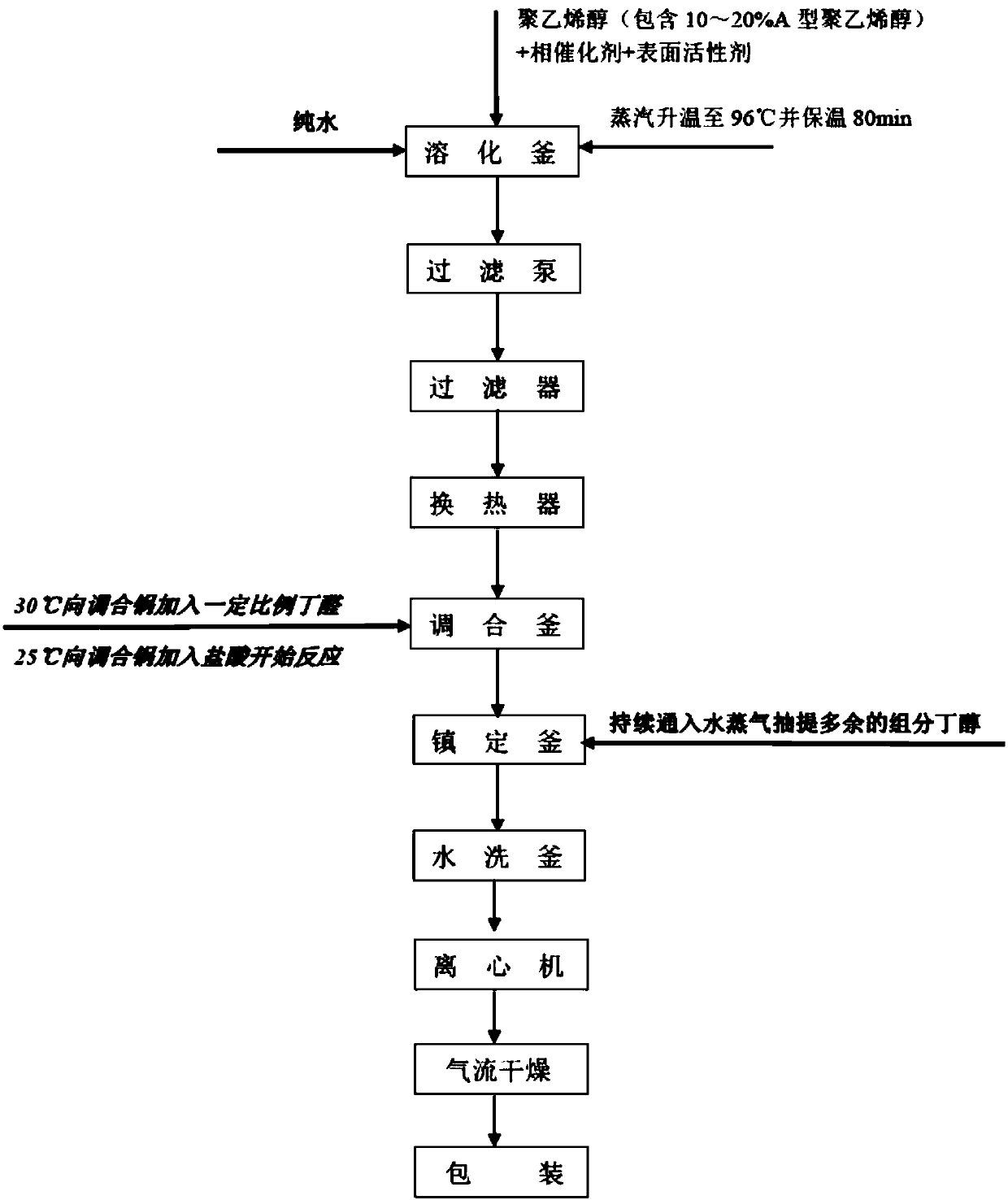

[0031] Such as figure 1 Shown, a kind of comprehensive performance high PVB resin powder preparation method of the present invention comprises the following steps:

[0032] (1) Dissolving: Put polyvinyl alcohol with a vinyl acetate (-COO-) content of 0.5% to 1% into a dissolution kettle for dissolution to make a polyvinyl alcohol solution;

[0033] The degree of alcoholysis of the polyvinyl alcohol is 99.0% to 99.5%, the melting temperature is 96°C and the holding time is 80min;

[0034] (2) Filtration and heat exchange: filter the polyvinyl alcohol solution dissolved in step (1) with a filter, and carry out heat exchange and filtration with a heat exchanger and pure water;

[0035] (3) Reaction: put the polyvinyl alcohol solution of step (2) into the blending kettle, and when the temperature of the polyvinyl alcohol solution is lowered to 30° C., add n-butyraldehyde to mix; Add hydrochloric acid at 25°C; the mixture of polyvinyl alcohol and n-butyraldehyde reacts with hydro...

example 1

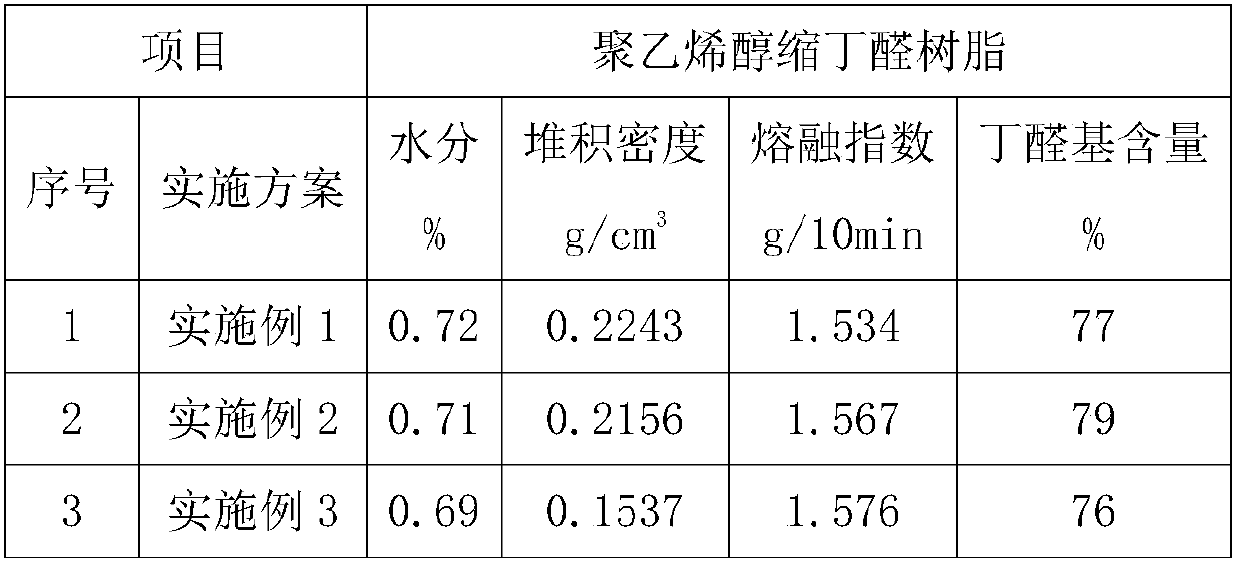

[0041] Add a total of 125g of polyvinyl alcohol containing type A polyvinyl alcohol into 1340ml of pure water, the quality of type A polyvinyl alcohol is 1-10% of the total amount of polyvinyl alcohol, keep stirring and raise the temperature to 96°C, and keep it warm for 80min . Then, when the temperature of the solution was lowered to 30° C., n-butyraldehyde was added and stirred. When the solution is cooled to 25°C, add hydrochloric acid, the mass ratio of hydrochloric acid to total polyvinyl alcohol is 12-15:100, the mass concentration of hydrochloric acid is 40%, and the mass ratio of n-butyraldehyde to total polyvinyl alcohol is 0.6. After the reaction took place, the temperature was raised to 60° C., and then kept for 2 hours. Sodium hydroxide was added to terminate the reaction, followed by washing with water. The washed polyvinyl butyral resin is dehydrated and dried to obtain the finished polyvinyl butyral resin.

[0042] Wherein, the molecular weight of the type A...

example 2

[0044] Add a total of 125g of polyvinyl alcohol containing type A polyvinyl alcohol into 1340ml of pure water, the quality of type A polyvinyl alcohol is 10-20% of the total amount of polyvinyl alcohol, keep stirring and raise the temperature to 96°C, and keep it warm for 80min . Then, when the temperature of the solution was lowered to 30° C., n-butyraldehyde was added and stirred. When the solution is cooled to 25°C, add hydrochloric acid, the mass ratio of hydrochloric acid to total polyvinyl alcohol is 12-15:100, the mass concentration of hydrochloric acid is 40%, and the mass ratio of n-butyraldehyde to total polyvinyl alcohol is 0.6. After the reaction took place, the temperature was raised to 60° C., and then kept for 2 hours. Sodium hydroxide was added to terminate the reaction, followed by washing with water. The washed polyvinyl butyral resin is dehydrated and dried to obtain the finished polyvinyl butyral resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com