Device for improving spun yarn performance through on-line controllable application of auxiliary agents in spinning

A technology of auxiliaries and performances is applied in the field of devices for controllable application of auxiliaries to improve spun yarn performance in spinning, which can solve the problems of reducing yarn hairiness, reducing yarn hairiness, and improving yarn performance without water-based solution components. Achieve the effect of improving the breaking strength of the yarn, reducing the number of hairiness and improving the comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and technical solutions.

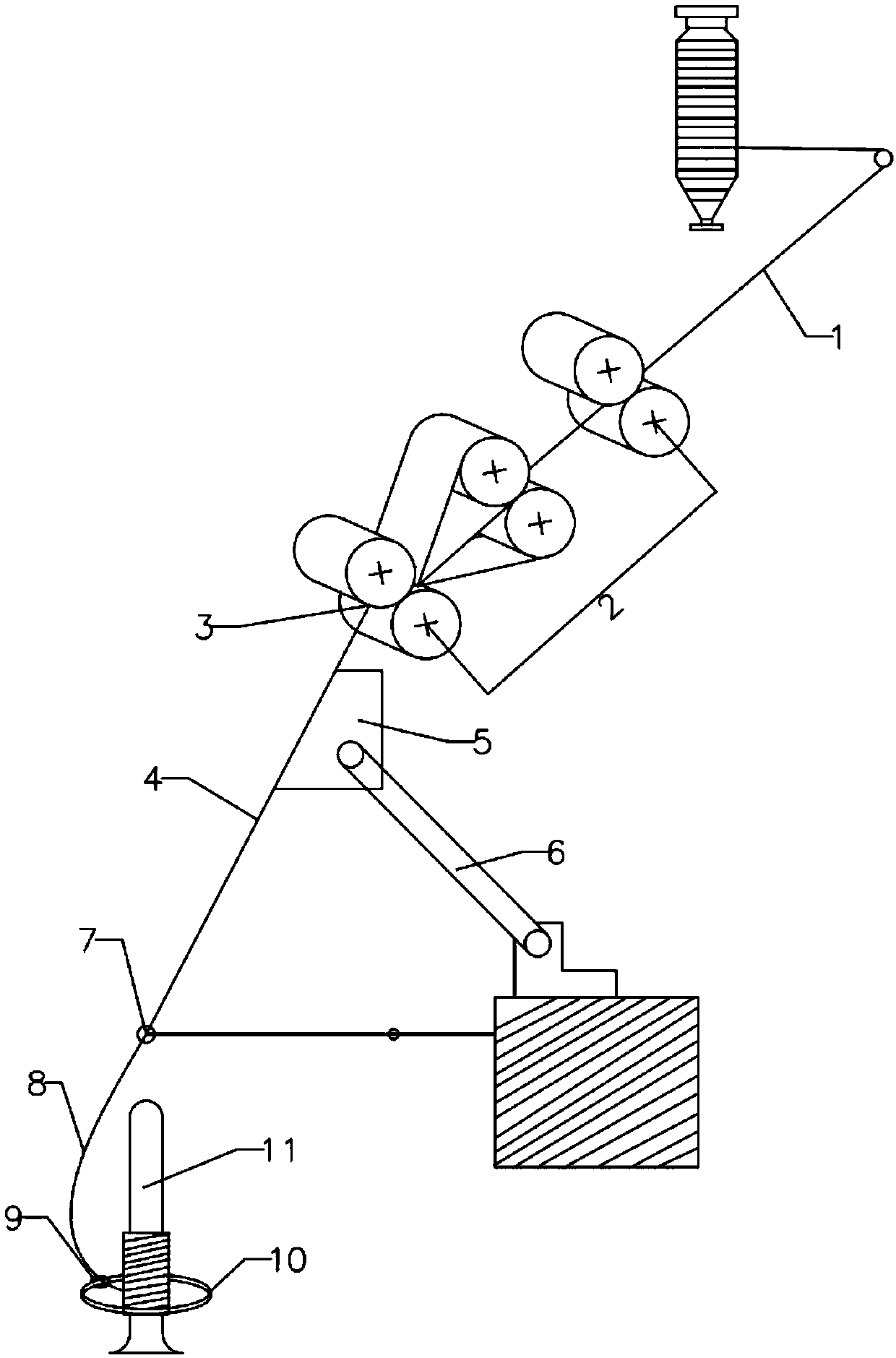

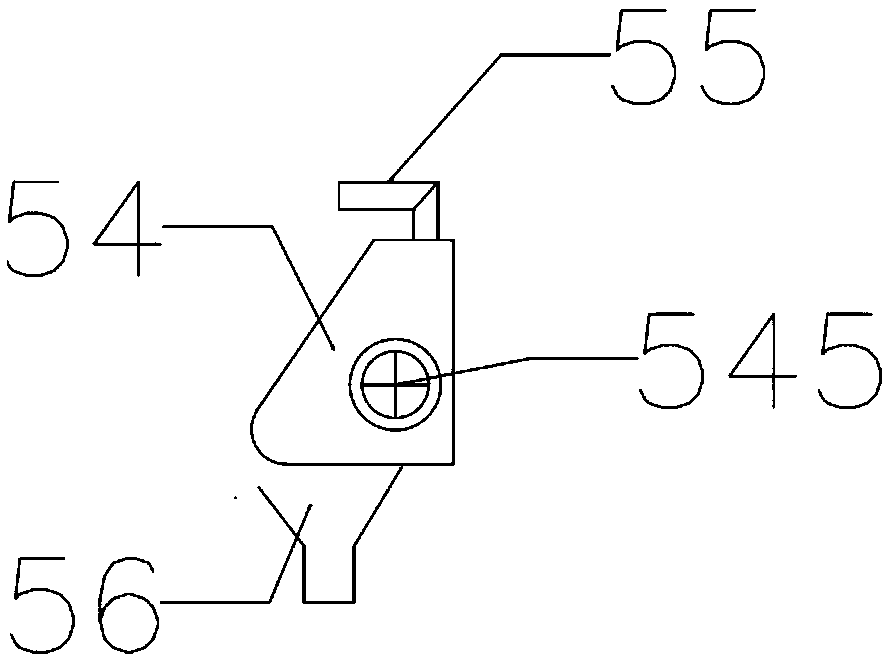

[0029] like Figure 1 to Figure 6 As shown, an auxiliary spinning device that can be liquid on the line, the auxiliary spinning device 5 is fixed on the ring spinning frame through its connecting screw 545 connecting the system fixing device 6, the auxiliary spinning device 5 is located between the front roller nip 3 and the yarn guide hook 7 of the ring spinning machine, and the twisted section yarn 4 output from the front roller nip 3 is subjected to liquid treatment by the auxiliary spinning device 5 .

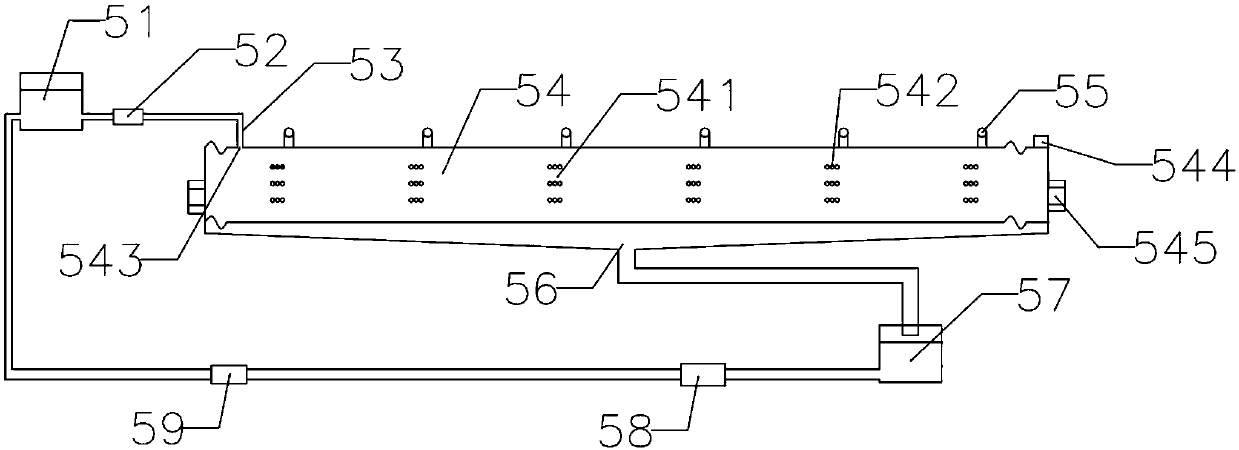

[0030] The auxiliary spinning device 5 includes a liquid supply system 51, a liquid supply pump 52, a connecting pipe 53, an upper liquid housing 54, a yarn guide rod 55, a solution collection tank 56, a solution recovery system 57, a recovery system 58 and Guide fluid pump 59;

[0031] The liquid supply pump 52 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com