Working environment detection system

A technology of working environment and detection system, which is applied in the field of circuits, can solve problems such as large detection errors in the working environment, reduce factory efficiency, and threaten worker safety, and achieve the effects of preventing signal instability, improving accuracy, and reducing signal potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

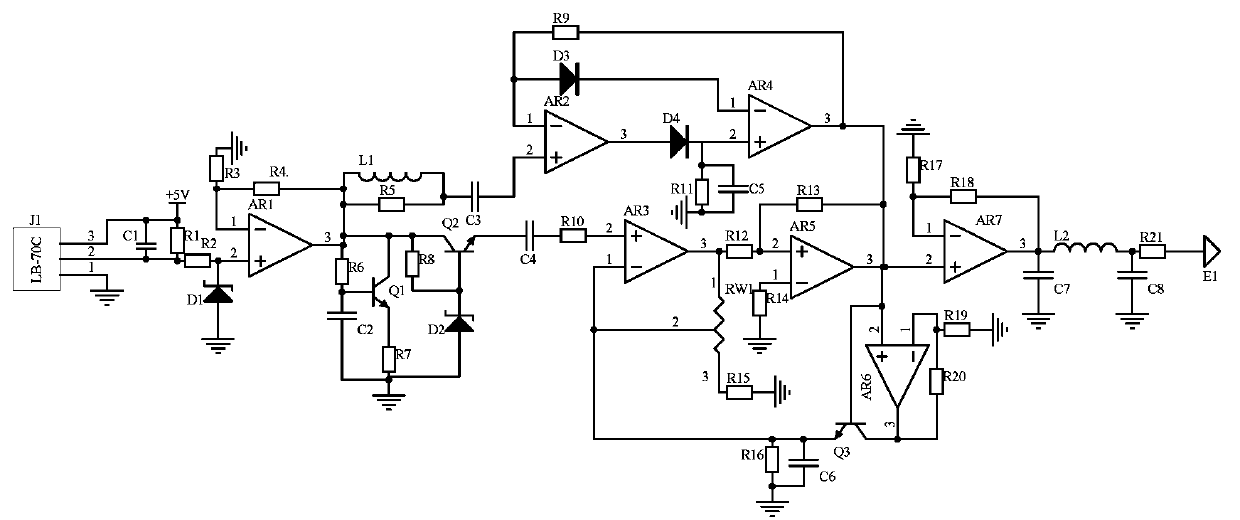

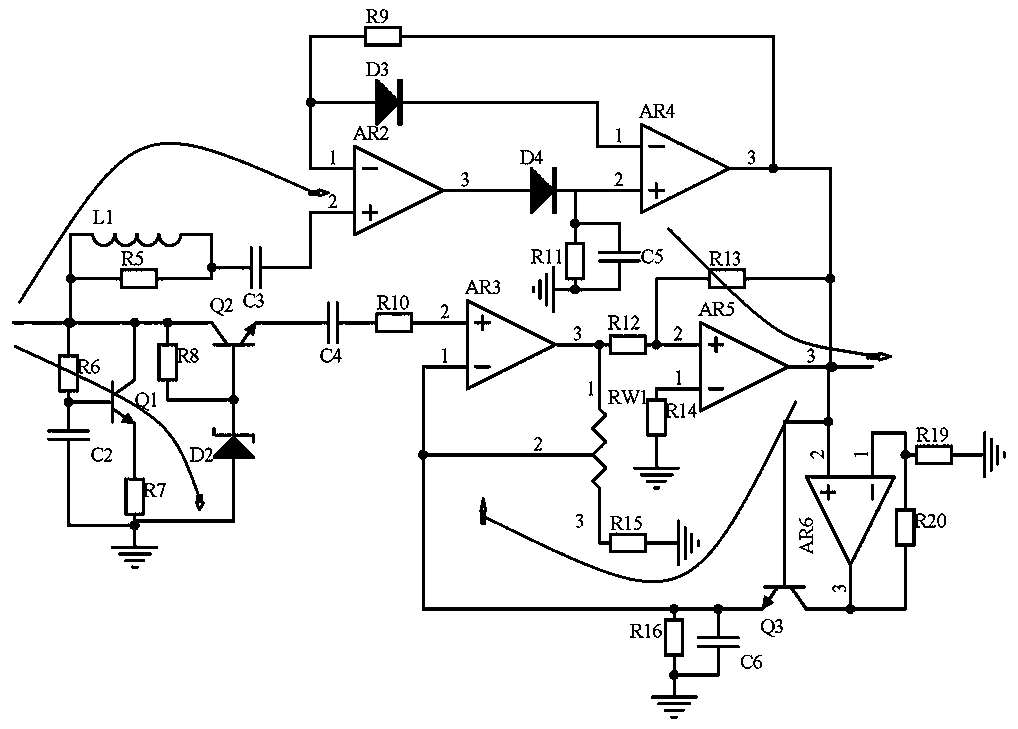

[0015] Embodiment 1, a working environment detection system, including a smoke and dust signal acquisition circuit, a feedback calibration circuit and an operational amplifier output circuit. The smoke and dust signal acquisition circuit uses a smoke and dust signal collector J1 model LB-70C to collect smoke and dust signals in the factory working environment , using the operational amplifier AR1 to amplify the signal in phase, the feedback calibration circuit is divided into two ways to receive the output signal of the smoke signal acquisition circuit, and one way is to use the inductance L1, the resistance R5 and the capacitance C3 to form a composite circuit to filter the high-frequency noise in the signal, and at the same time use The operational amplifier AR2, operational amplifier AR4, diode D3, and diode D4 form a peak detection circuit to adjust the peak value of the signal. The second circuit uses the transistor Q1, resistor R6, and capacitor C2 to form a delay circuit ...

Embodiment 2

[0018] Embodiment 2. On the basis of Embodiment 1, the operational amplifier output circuit uses the operational amplifier AR7 to amplify the signal in phase, amplifies the signal power, and compensates the conduction loss of the signal. At the same time, it is composed of the inductor L2, the capacitor C7, and the capacitor C8. The output is filtered by the π-type filter circuit to filter out the clutter of the signal, that is, it is sent to the factory operating environment monitoring terminal through the signal transmitter E1, realizing real-time monitoring of the factory operating environment. The non-inverting input terminal of the operational amplifier AR7 Connect the output terminal of the operational amplifier AR5, the inverting input terminal of the operational amplifier AR7 is connected to one end of the resistor R17 and the resistor R18, the other end of the resistor R17 is grounded, and the output terminal of the operational amplifier AR7 is connected to the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com