Method for processing solar cell piece

A solar cell sheet and processing method technology, which is applied in the field of solar cells, can solve the problems of complicated process and impracticality, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

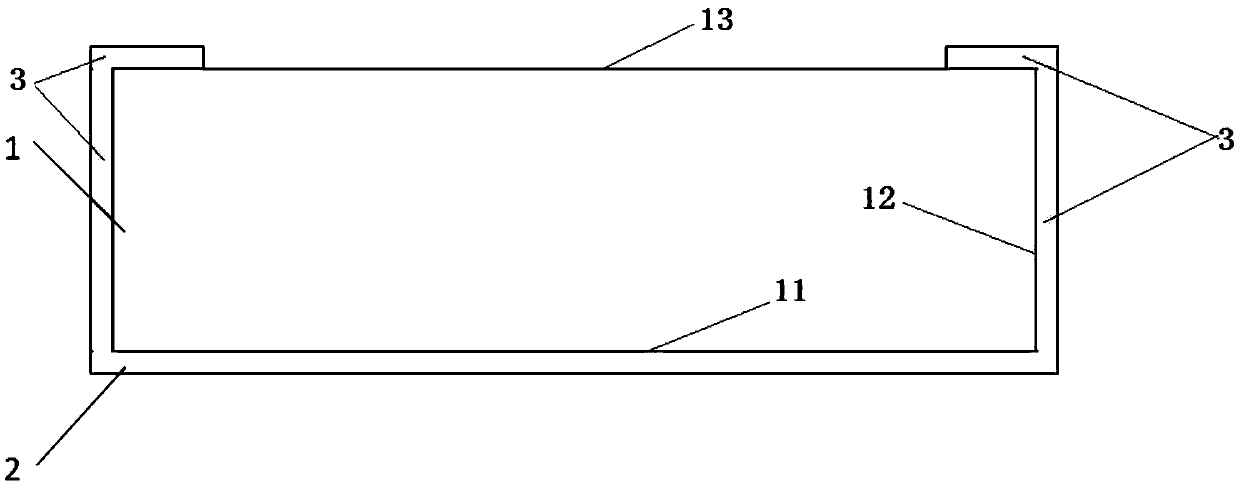

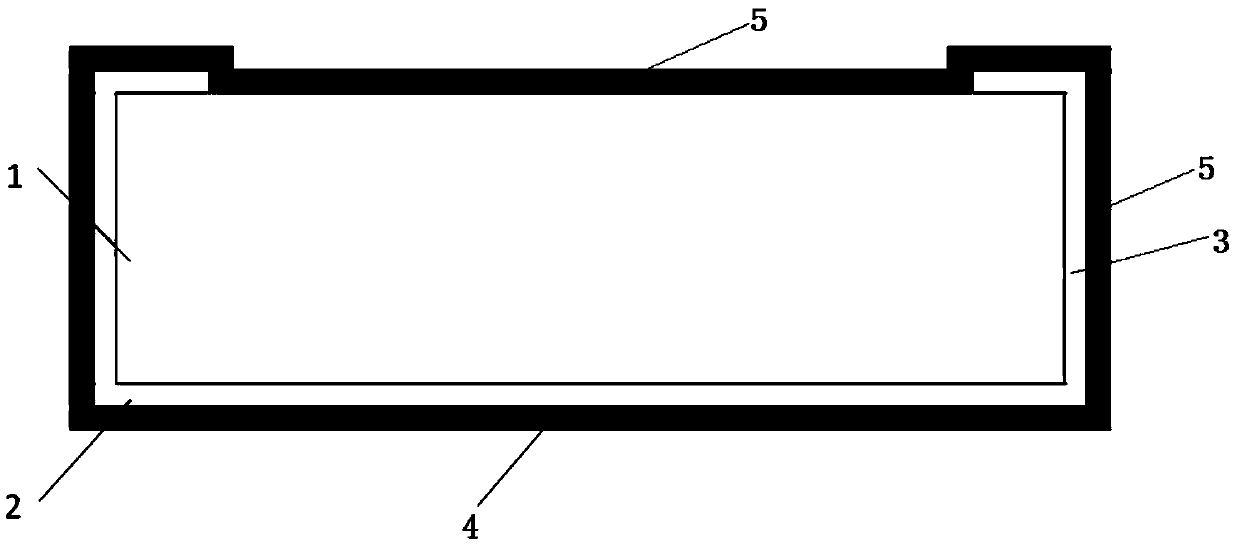

[0078] Using the solar cell processing method provided in this embodiment, that is, the solar cell structure after the silicon thin film asymmetric etching process is as follows Figure 6 As shown, a silicon substrate 1 is included, and a first silicon thin film layer 2 is provided on the first main surface of the silicon substrate 1 .

[0079] The thickness of the first silicon thin film layer is 100 nm.

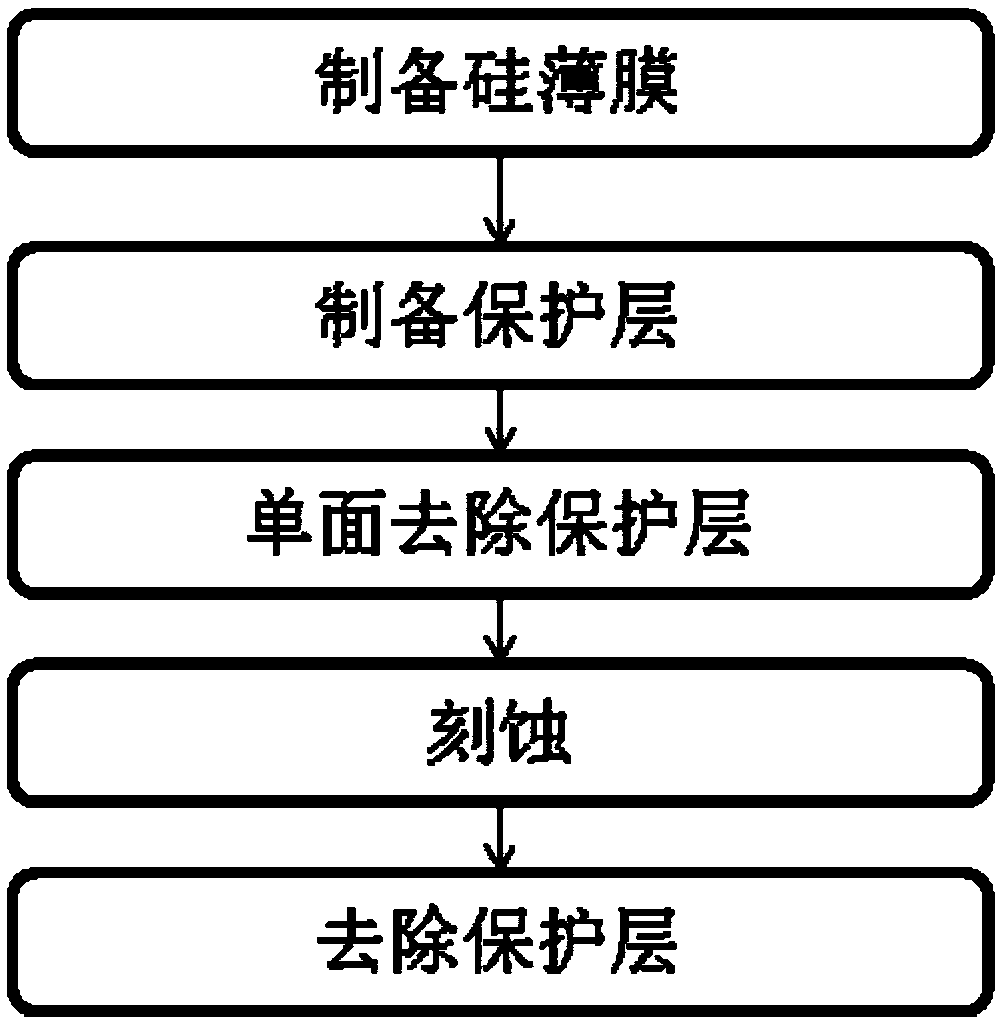

[0080] This embodiment illustrates a method for processing solar cells, which can also be called asymmetric etching of silicon thin films. This method is to remove the silicon thin film layer around the plating surface by pure chemical etching, such as figure 1 , including the following steps:

[0081] S1. Preparation of silicon thin film: place a clean silicon substrate 1 in a low-pressure chemical deposition (LPCVD) device to grow a 100nm non-doped first silicon thin film layer 2 and a second silicon thin film layer 3, wherein the first silicon thin film layer 2 is set ...

Embodiment 2

[0087] Using the solar cell processing method provided in this embodiment, that is, the solar cell structure after the silicon thin film asymmetric etching process is as follows Figure 6 As shown, a silicon substrate 1 is included, and a first silicon thin film layer 2 is provided on the first main surface of the silicon substrate 1 .

[0088] The thickness of the first silicon thin film layer is 200nm, including 100nm of undoped silicon thin film and 100nm of phosphorus (P) doped silicon thin film.

[0089] This embodiment illustrates a method for processing solar cells, which can also be called asymmetric etching of silicon thin films. This method is to remove the silicon thin film layer around the plating surface by pure chemical etching, such as figure 1 , including the following steps:

[0090] S1. Preparation of silicon thin film: place a clean silicon substrate 1 in a plasma chemical deposition (PECVD) device to grow a 100nm non-doped first silicon thin film layer 2 a...

Embodiment 3

[0096] Using the solar cell processing method provided in this embodiment, that is, the solar cell structure after the silicon thin film asymmetric etching process is as follows Figure 7 As shown, a silicon substrate 1 is included, a passivation dielectric layer 6 (specifically a silicon oxide layer) is provided on the first main surface 11 of the silicon substrate 1 , and a first silicon thin film layer 2 is provided on the passivation dielectric layer 6 .

[0097] Wherein the passivation medium layer 6 has a thickness of 1.2 nm.

[0098] The thickness of the first silicon thin film layer 2 is 300nm, including 200nm undoped silicon thin film layer and 100nm phosphorus (P) doped silicon thin film layer.

[0099] This embodiment illustrates a method for processing solar cells, which can also be called asymmetric etching of silicon thin films. This method is to remove the silicon thin film layer around the plating surface by pure chemical etching, such as figure 1 , including ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com