A method for resource utilization of waste cathode materials of lithium batteries

A cathode material and recycling technology, which is applied in the field of resource utilization of waste cathode materials for lithium batteries, can solve the problems of difficult impurity removal and low process efficiency, and achieve high-quality solutions, easy impurity removal and purification, and high-efficiency recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

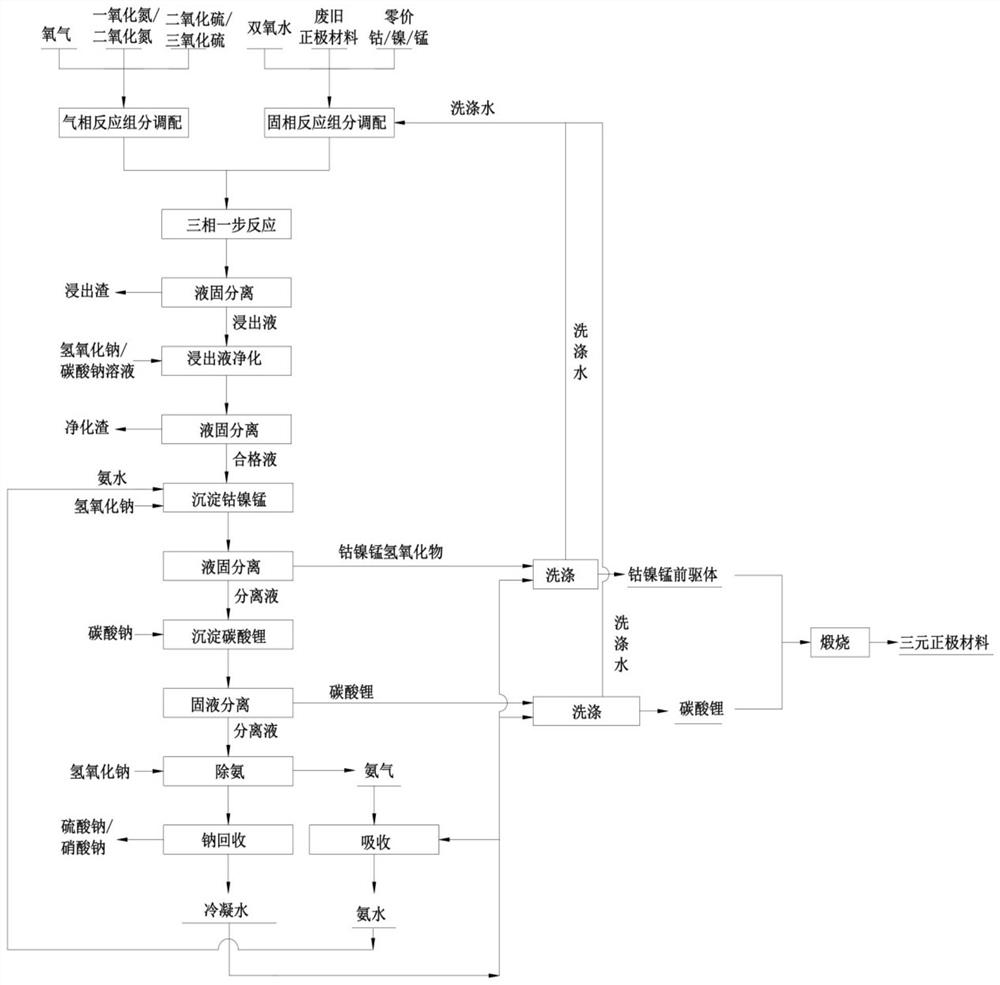

Method used

Image

Examples

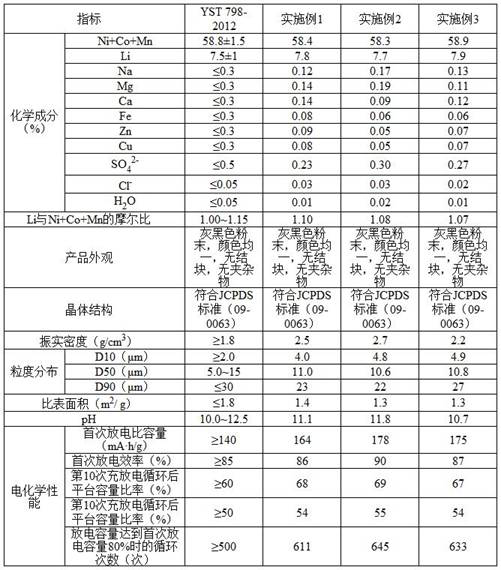

Embodiment 1

[0063] A method for recycling waste cathode materials of lithium batteries, comprising the following steps:

[0064] (1) Preparation of liquid-solid reaction components: Mix 10 kg of waste cathode material powder that has been crushed and passed through an 80-mesh sieve with 1 kg of zero-valent cobalt powder to obtain 11 kg of solid components; mix the obtained solid components with 25 L of steam condensate After mixing and pulping, and stirring evenly, add 450ml of 30% hydrogen peroxide to obtain liquid-solid reaction components that meet the requirements.

[0065] (2) Preparation of gas phase reaction components: Mix pure nitric oxide, nitrogen dioxide and oxygen according to the volume ratio of 1 : 0.5 : 1 to obtain the required mixed gas of nitric oxide, nitrogen dioxide and oxygen gas phase reaction components;

[0066](3) Three-phase one-step reaction: The liquid-solid phase reaction components obtained in step (1) and the gas-phase reaction components obtained in step ...

Embodiment 2

[0075] A method for recycling waste cathode materials of lithium batteries, comprising the following steps:

[0076] (1) Preparation of liquid-solid reaction components: Mix 10kg of waste cathode material powder, 0.2kg of zero-valent cobalt, and 0.8kg of manganese after crushing and passing through a 100-mesh sieve to obtain 11kg of solid mixed components; Divide and mix with 50 L of steam condensed water, stir evenly and add 550 ml of hydrogen peroxide with a concentration of 28% to obtain a solid phase reaction component that meets the requirements;

[0077] (2) The deployment of gas phase reaction components: the exhaust gas containing 10% nitric oxide concentration and 10% oxygen concentration is passed into the catalytic reactor, so that part of the nitric oxide is converted into nitrogen dioxide, and the nitric oxide concentration is obtained A mixed gas with 8% nitrogen dioxide concentration, 2% nitrogen dioxide concentration and 9% oxygen concentration;

[0078] (3) T...

Embodiment 3

[0087] A method for recycling waste cathode materials of lithium batteries, comprising the following steps:

[0088] (1) Preparation of liquid-solid reaction components: Mix 20kg of waste cathode material powder, 0.5kg of zero-valent manganese, 0.5kg of zero-valent nickel and 0.5kg of zero-valent cobalt that have been crushed and passed through a 120-mesh sieve to obtain 21.5kg of solid Mixed components: Mix the obtained solid mixed components with 50 L of steam condensed water, stir evenly and add 600 ml of hydrogen peroxide with a concentration of 28% to obtain a solid phase reaction component that meets the requirements;

[0089] (2) Preparation of gas-phase reaction components: add nitrogen dioxide gas to the waste gas containing 1% nitric oxide and 10% oxygen to obtain a concentration of nitric oxide, nitrogen dioxide and oxygen of 1 : 0.5 : 10 mixed composition;

[0090] (3) Three-phase one-step reaction: Send the liquid-solid phase reaction components obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com