Method capable of reducing viscosity of dough containing whole wheat flour

A dough and all-flour technology, applied in the direction of dough preparation, pre-baked dough treatment, yeast-containing food ingredients, etc., can solve the problems of weak dough strength, high viscosity, sticky wall, etc., and achieve good quality and reduced cooking loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

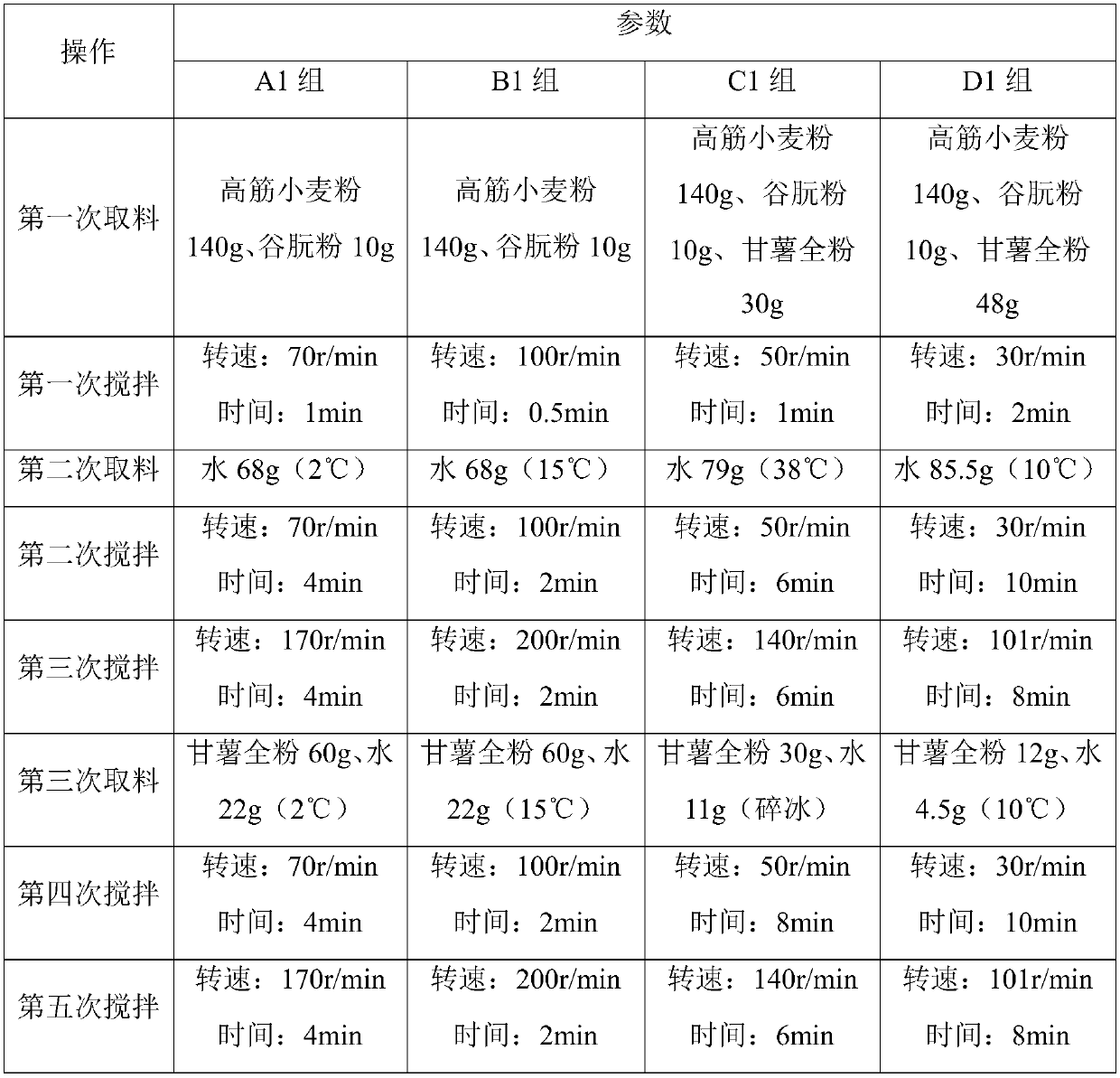

[0062] Embodiment 1: the preparation of sweet potato whole powder dough (the whole powder addition is 30%)

[0063] Specific steps are as follows:

[0064] (1) Take the material for the first time, mix it evenly and add it to the mixing tank, turn on the mixer and stir for the first time to obtain part of the mixed raw material;

[0065] (2) Take the material for the second time, add it to the mixing tank, and then perform the second stirring and the third stirring in turn to obtain a uniform batter;

[0066] (3) Take the material for the third time, add it to the mixing tank, and then stir it for the fourth time and the fifth time successively to obtain the finished dough;

[0067] Wherein, the parameter of taking material has: water yield (when the material that gets is water, also should indicate water temperature), sweet potato powder amount, yeast amount; The parameter of described stirring has: stirring speed, stirring time (concrete parameter setting can see table 1)....

Embodiment 2

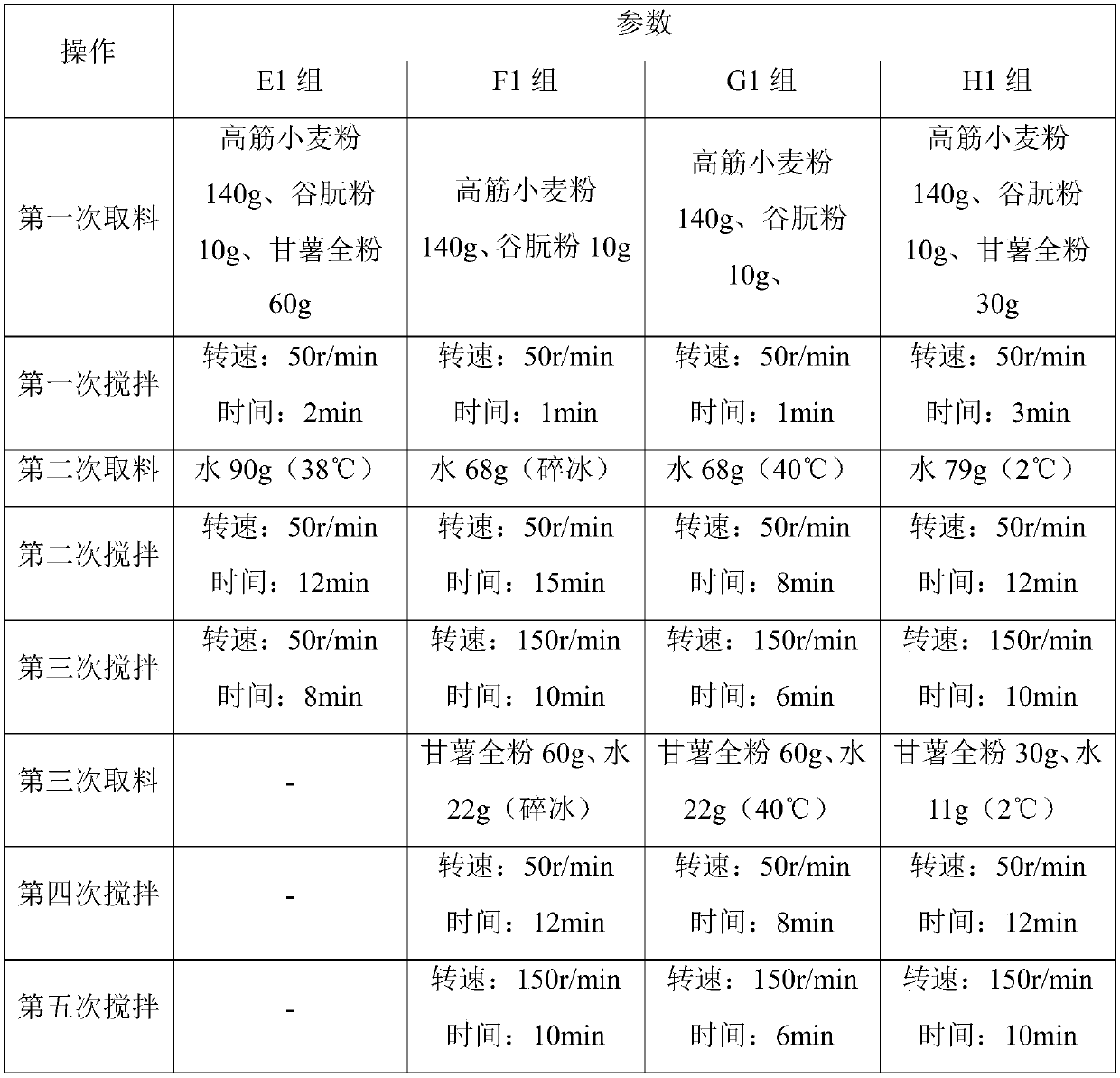

[0071] Embodiment 2: the preparation of sweet potato whole powder dough (the whole powder addition is 30%)

[0072] Specific steps are as follows:

[0073] (1) Take the material for the first time, mix it evenly and add it to the mixing tank, turn on the mixer and stir for the first time to obtain part of the mixed raw material;

[0074] (2) Take out the material for the second time, add it to the mixing tank, carry out the second stirring and the third stirring in turn, to obtain a uniform dough, take it out for use;

[0075] (3) Take the material for the third time, add it to the mixing tank, and carry out the fourth stirring in turn to obtain a uniform whole powder paste;

[0076] (4) Take out the material for the fourth time, take out the uniform dough prepared in (2), cut it into small pieces, put it into the mixing tank, and carry out the fifth and sixth stirring in turn to obtain the finished dough.

[0077] Wherein, the parameter of taking material has: water yield (...

Embodiment 3

[0092] Embodiment 3: the preparation of sweet potato whole powder noodles (the whole powder addition is 30%)

[0093] Specific steps are as follows:

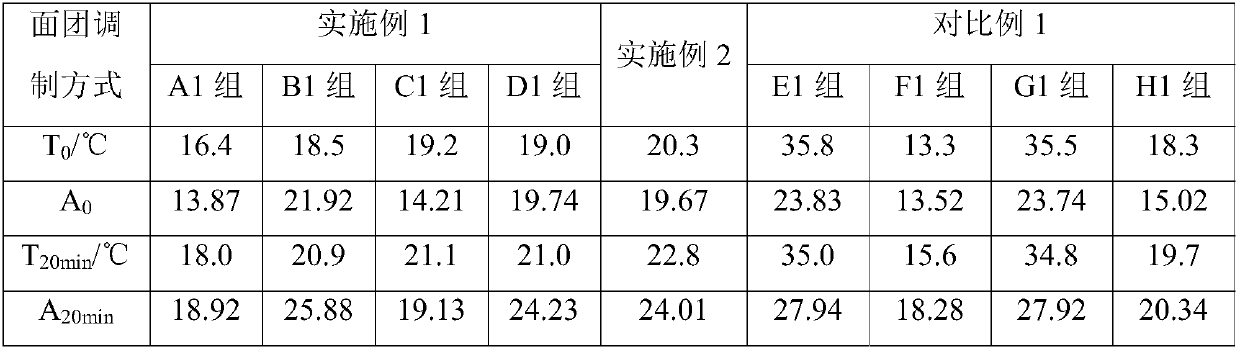

[0094] (1) Take the finished dough products of Examples 1-2 and Comparative Example 1, wrap them in plastic wrap and leave to mature for 20 minutes at a room temperature of 25° C. to obtain mature dough;

[0095] (2) Roll the matured dough with an automatic noodle machine, first rolling once at the gauge of 2mm, after folding the noodle strips into 3-4 layers, repeatedly folding and rolling at the gauge of 3.5mm for 6 times, and then rolling them on the gauge in turn. Fold and roll three times at distances of 3 mm, 2 mm, and 1 mm, and finally cut into strips and dry naturally at room temperature to obtain sweet potato all-flour noodles.

[0096] The sweet potato whole powder noodles were tested for the breaking rate of noodles and the cooking loss of noodles. The test results are shown in Table 5.

[0097] Table 4 Dough temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com