A kind of bridging agent for liquid quick-freezing and preparation method thereof

A refrigerant and liquid technology, which is applied in the preparation of liquid quick-freezing refrigerant and the field of liquid quick-freezing refrigerant, can solve the problems of high cost, insufficient stability, high freezing point of alcohol refrigerant, and achieve viscosity The effect of small size, lower temperature and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A liquid quick-freezing refrigerant, which is composed of the following components in mass percentage: 3% citric acid, 10% fructooligosaccharide, 2.5% calcium chloride, 19.5% edible ethanol, 9.5% food grade propylene glycol, sodium chloride 2.5%, water 53%.

[0035] The preparation method of the brine for the above-mentioned liquid quick-freezing comprises the following steps:

[0036] When preparing, first dissolve citric acid, calcium chloride, sodium chloride, and fructooligosaccharides in water, add propylene glycol, stir evenly, and then add ethanol to obtain the brine for liquid quick-freezing in this embodiment.

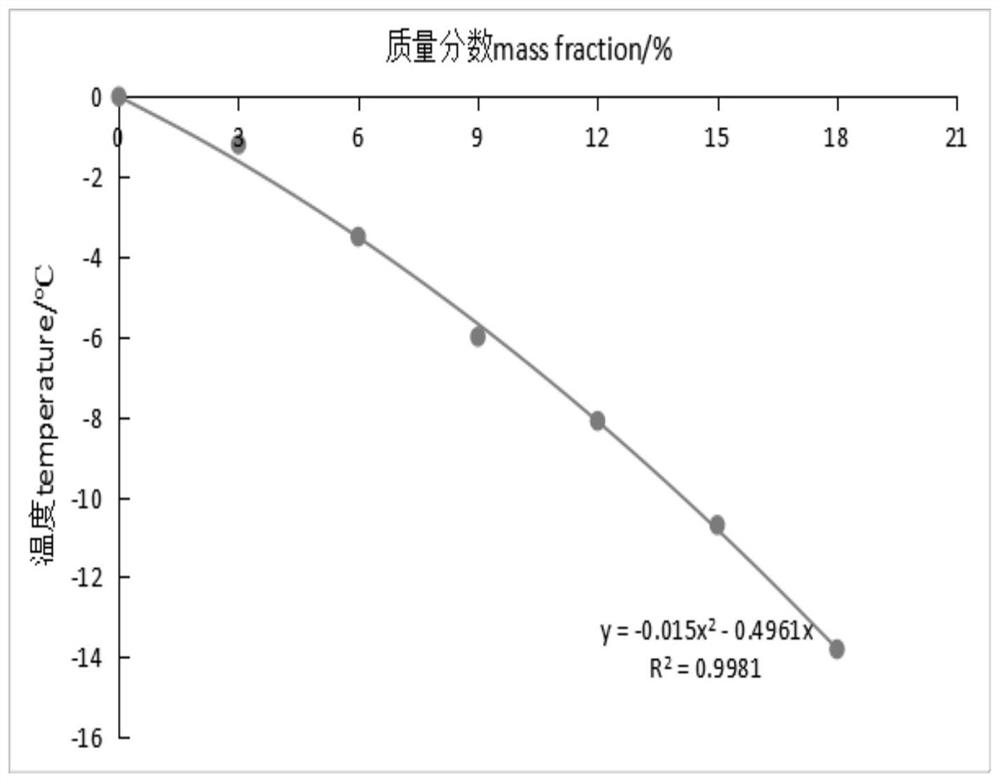

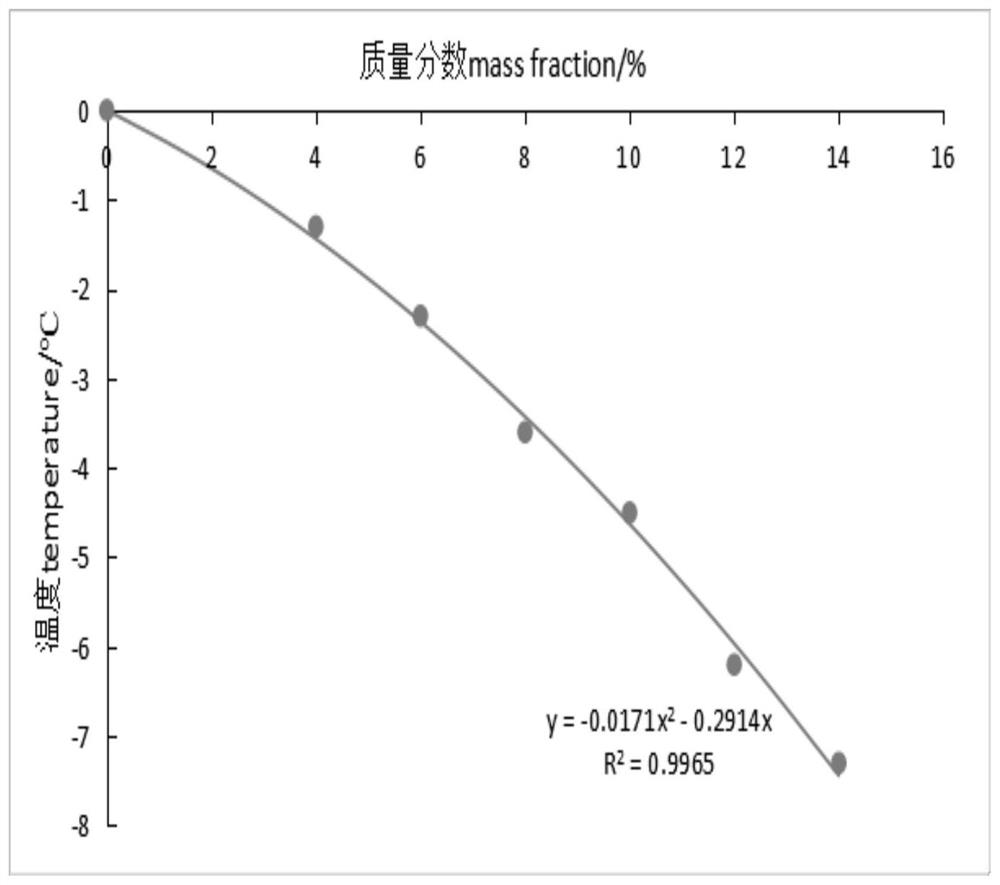

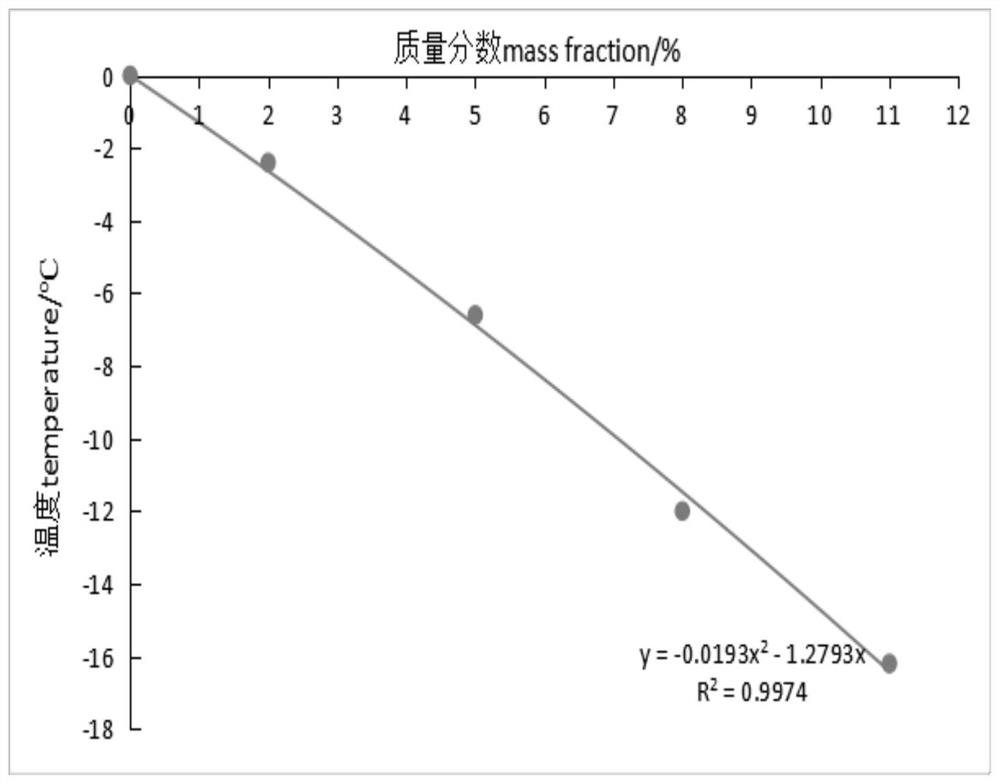

[0037] Figure 1-Figure 4 It is citric acid, fructo-oligosaccharide, calcium chloride, ethanol and propylene glycol mixed with water respectively in the refrigerant of the liquid quick-freezing of the present invention, and the changing situation of the freezing point of solutions in different additions in water. From these curves, it can be seen that ...

Embodiment 2

[0040] A liquid quick-freezing refrigerant, composed of the following components in mass percentage: 3.5% citric acid, 9% fructooligosaccharide, 3.5% calcium chloride, 15.6% edible ethanol, 9.9% food grade propylene glycol, sodium chloride 1.5%, water 57.0%.

[0041] The preparation method of the brine for liquid quick-freezing in this embodiment is the same as that in Embodiment 1.

[0042] Taking grouper fillets as an example, the grouper fillets are trimmed, and the grouper fillets with a size of 5cm*0.5cm*3cm are neatly placed on food-grade plastic trays and vacuum-packed. Put the liquid quick-freezing brine prepared by the above formula into the quick-freezing machine, first cool down the brine to the set temperature -50°C, then put the packaged grouper fillets into the brine, and freeze until It only takes 15 minutes for the core temperature to reach below -18°C.

Embodiment 3

[0044] A liquid quick-freezing refrigerant, composed of the following components in mass percentage: 5.5% citric acid, 12% fructooligosaccharide, 4% calcium chloride, 19.9% edible ethanol, 7.9% food grade propylene glycol, sodium chloride 2%, water 48.7%.

[0045]The preparation method of the brine for liquid quick-freezing in this embodiment is the same as that in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com