Method for intensifying fermentation process of tobacco leaves

A fermentation process and tobacco leaf technology, applied in tobacco, tobacco processing, application, etc., can solve problems affecting the safety of snus consumption, and achieve the effects of improving practical safety, increasing fineness, and improving smoke quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

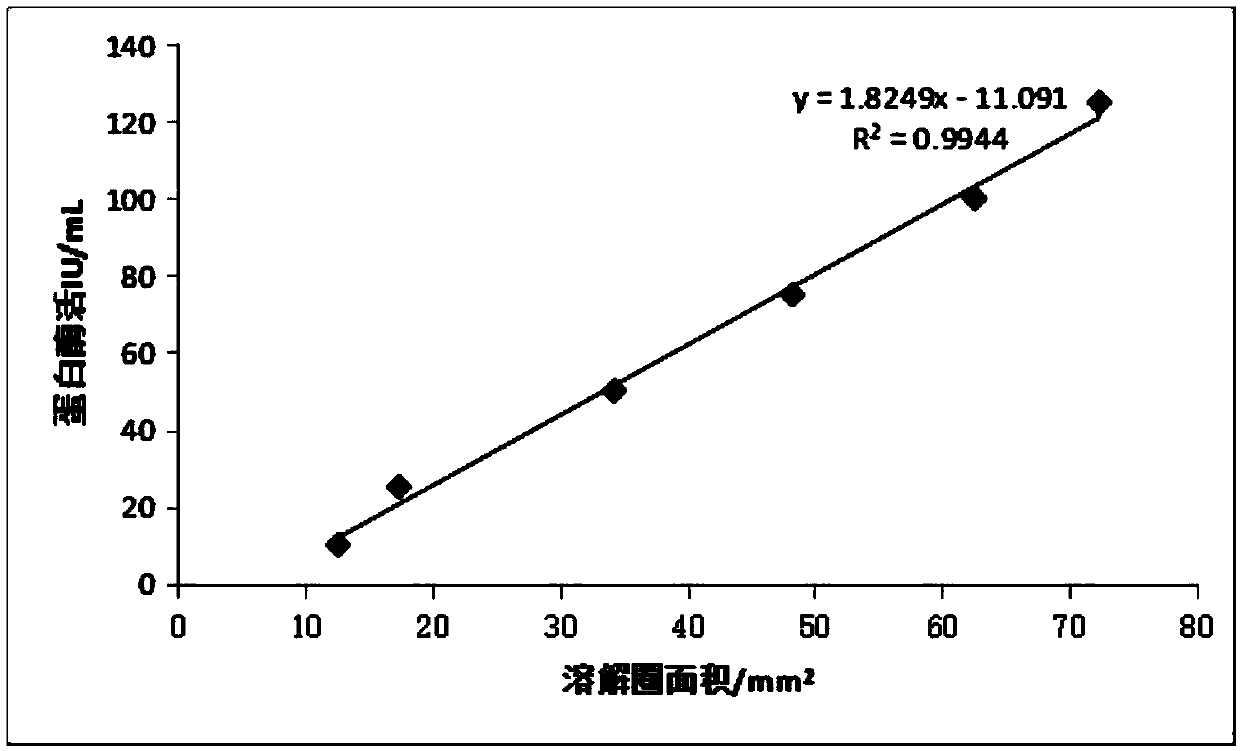

Image

Examples

Embodiment 1

[0023] This embodiment is the preparation of Bacillus amyloliquefaciens GUHP-86 preparation, which specifically includes the following steps:

[0024] (1) Weigh 1.25g of tryptone, 0.625g of yeast extract, 6.25g of NaCl, and 0.625g of glucose, add distilled water to 1000mL, and sterilize by high-pressure steam at 121°C for 20min, and insert the Bacillus amyloliquefaciens after cooling GUHP-86 was cultured at 37°C and 180r / min for 18h±2h to obtain seed liquid;

[0025] (2) centrifuge 1000mL of the seed liquid at 4°C and 8000r for 10min, collect the precipitate, and wash the precipitate with 8.5g / L sterilized physiological saline, then add 1000mL of sterilized physiological saline to the precipitate, Shake well to obtain the Bacillus amyloliquefaciens GUHP-86 preparation.

[0026] The Bacillus amyloliquefaciens GUHP-86 was preserved in China Center for Type Culture Collection on January 4, 2016, with the preservation number CCTCC M 2016003.

[0027] The sterilized physiological...

Embodiment 2

[0029] In the present embodiment, take 20g tobacco leaf in the sealed bag of 14cm * 20cm specification, draw 2mL described Bacillus amyloliquefaciens GUHP-86 preparation (being 10% inoculum size) in tobacco leaf, 4mL has sugar-salt solution in tobacco leaf, fully Mix well to obtain sample 1.

[0030] The preparation steps of the sugar-salt solution are as follows: Weigh the MgCl 2 5g, KCl 0.5g, CaCl 2 0.5g, 0.5g NaCl, 2g glucose, add water to 1000mL, dissolve to obtain a sugar-salt solution.

[0031] Weigh 20g of tobacco leaves into a sealed bag with a size of 14cm×20cm, draw 2mL of sterile physiological saline and 4mL of sugar-salt solution into the tobacco leaves, and mix well to obtain Comparative Sample 1.

[0032] The sample 1 and the comparison sample 1 were cultured in the 37°C incubator at the same time, and the ventilation was carried out regularly every day, and when the humidity decreased, there must be added sugar and salt solution.

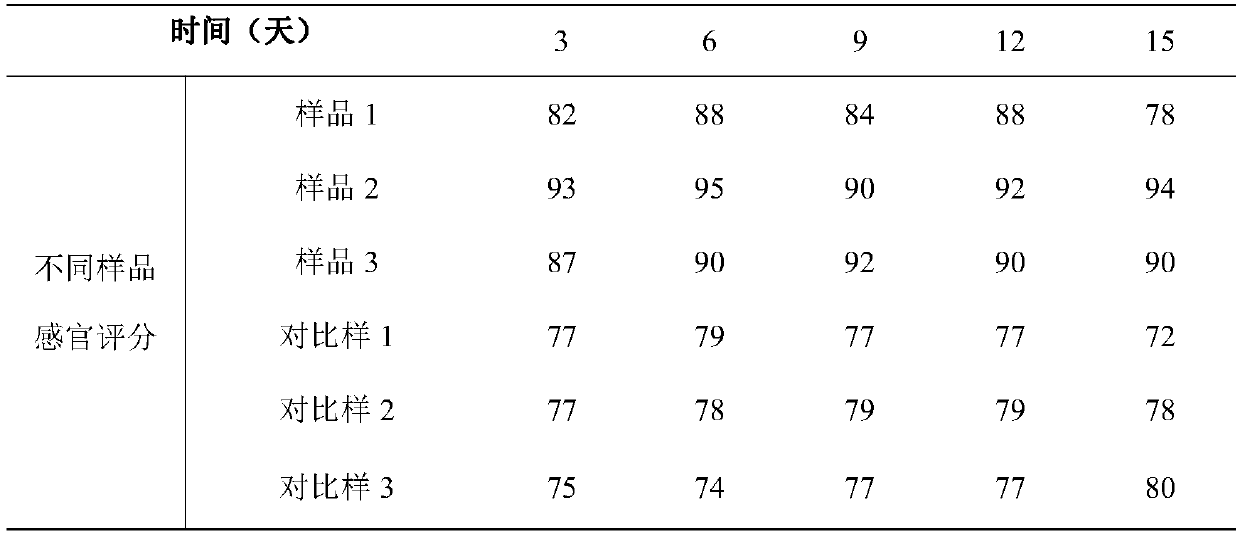

[0033] The sensory evalua...

Embodiment 3

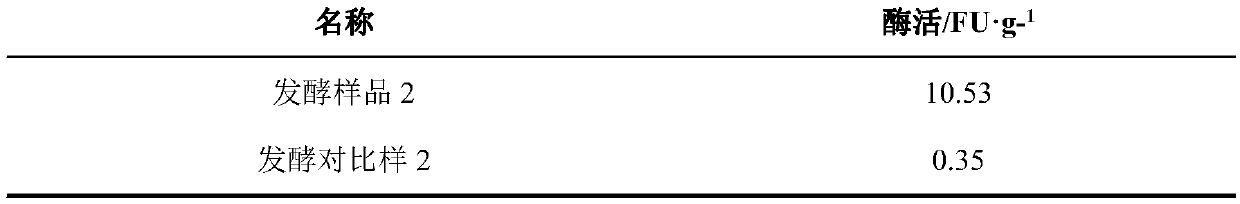

[0036]In the present embodiment, take 20g tobacco leaf in the sealed bag of 14cm * 20cm specification, draw 4mL described Bacillus amyloliquefaciens GUHP-86 preparation (being 20% inoculum size) in tobacco leaf, 4mL has sugar-salt solution in tobacco leaf, fully Mix well to obtain sample 2.

[0037] The preparation steps of the sugar-salt solution are as follows: Weigh the MgCl 2 5g, KCl 0.5g, CaCl 2 0.5g, 0.5g NaCl, 2g glucose, add water to 1000mL, dissolve to obtain a sugar-salt solution.

[0038] Weigh 20g of tobacco leaves into a sealed bag with a size of 14cm×20cm, draw 4mL of sterile physiological saline and 4mL of sugar-salt solution into the tobacco leaves, and mix well to obtain Comparative Sample 2.

[0039] The sample 2 and the comparison sample 2 were cultivated in the incubator at 37°C at the same time, and the ventilation was carried out regularly every day, and when the humidity decreased, a sugar-salt solution must be added.

[0040] More than 10 sensory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com