Method for synthesizing metal organic skeleton composite film under action of assisted deposition of catechol compounds

A technology of metal-organic framework and synthesis method, which is applied in the field of catechol compound-assisted deposition to synthesize metal-organic framework composite membranes, can solve the problems of limiting the use types of organic basement membranes, achieve good application value and prospects, and have wide versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

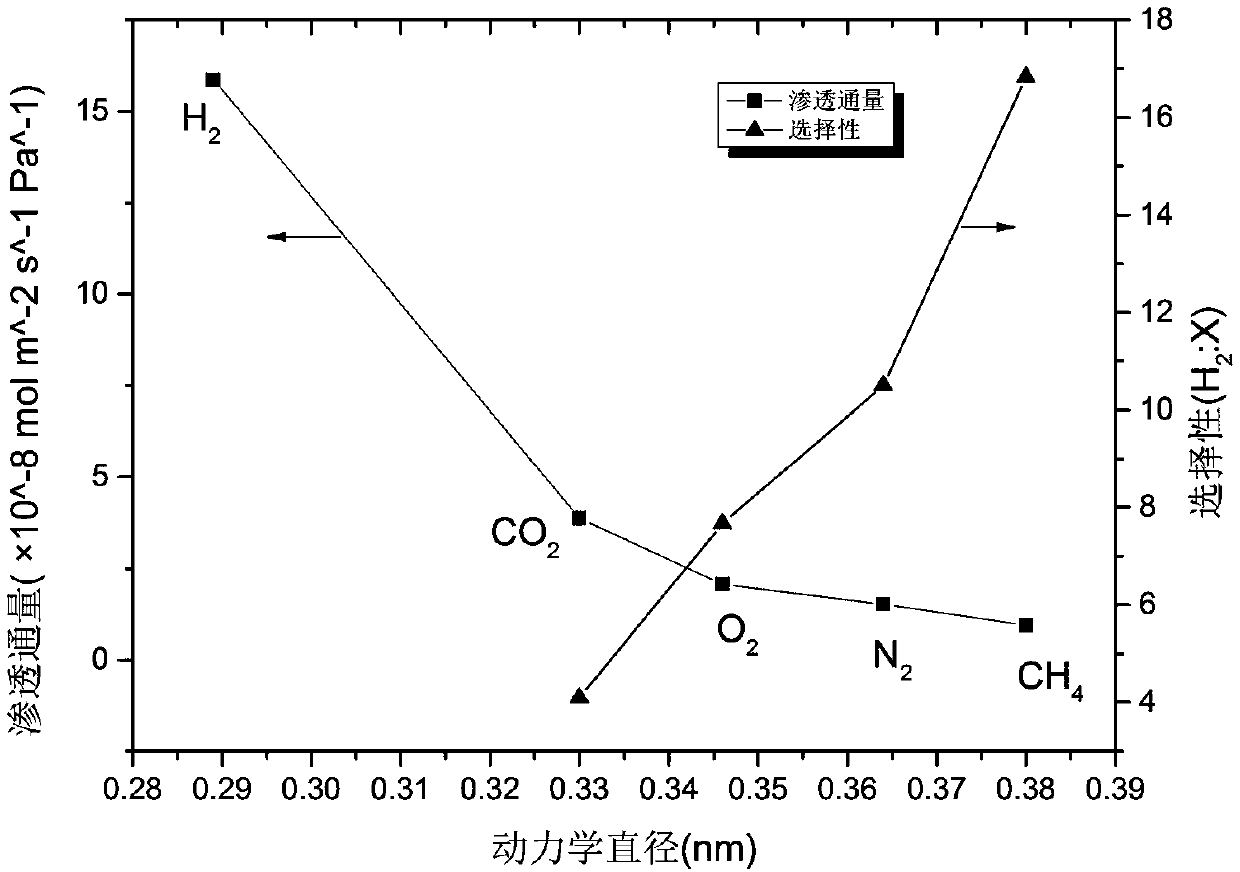

[0034] Example 1: The substrate is a polyethersulfone hollow fiber membrane, and the metal-organic framework membrane synthesized is a polyethersulfone / ZIF-8 membrane by using a modification method of polyvinylamine and levodopa-assisted deposition.

[0035] Preparation:

[0036] (1) Modification of polyethersulfone hollow fiber membranes: the substrate is polyethersulfone hollow fiber membranes, and the modification method using polyvinylamine and levodopa-assisted deposition, polyvinylamine (0.15g) and levodopa (0.05 g) Add to Tris-HCl buffer solution (25mL, pH=8.5), put the polyethersulfone hollow fiber membrane sealed at both ends and vibrate at 100r / min for 6h. Take out the film, blow off the excess liquid attached to the surface of the film with airflow, support it with a self-made support and put it in an oven to dry for use.

[0037] (2) Synthesis of polyethersulfone / ZIF-8 membrane: put the modified polyethersulfone hollow fiber membrane obtained in step (1) into the ...

Embodiment 2

[0039] Example 2: The substrate is a polyethersulfone hollow fiber membrane, tannic acid is used as a modifier, and the synthesized metal-organic framework membrane is a polyethersulfone / ZIF-8 membrane.

[0040](1) Modification of polyethersulfone hollow fiber membranes: tannic acid (0.5mg / mL) and zinc acetate (0.3mg / mL) aqueous solutions were prepared by tannic acid complexed metal ion deposition method to adjust the tannic acid Solution pH=8. The polyethersulfone hollow fiber membrane was repeatedly immersed in the above two solutions, and the solution was continuously shaken for 30 seconds, repeated 7 times. After the membrane was taken out, it was rinsed several times with deionized water and left to dry in the air.

[0041] (2) Synthesis of polyethersulfone / ZIF-8 membrane: put the modified polyethersulfone hollow fiber membrane obtained in step (1) into the prepared MOF precursor solution, and perform solvothermal synthesis at 85°C for 24h, After the reaction system was...

Embodiment 3

[0043] Example 3: The substrate is α-Al 2 o 3 Porous flat membrane, tannic acid as modifier, synthesized metal-organic framework membrane as α-Al 2 o 3 / CuBTC film.

[0044] Preparation:

[0045] (1) Preparation of polysulfone flat membrane containing copper gel: the substrate was modified by tannic acid complexed metal ion deposition method, and tannic acid (1.0 g) and copper sulfate (0.1 g) were added to deionized water ( 50mL), the pH was adjusted to be greater than 7, and the α-Al 2 o 3 One side of the porous flat membrane was immersed in the above solution for 1 h. After the membrane was taken out, it was rinsed several times with deionized water and left to dry in the air.

[0046] (2)α-Al 2 o 3 / CuBTC film synthesis: the modified α-Al obtained in step (1) 2 o 3 The flat film was put into the prepared MOF precursor solution, and the solvothermal synthesis was carried out at 110 °C for 18 hours. After the reaction system was cooled, the film was taken out and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com