Controllable preparation method of liposome vesicle based on microfluidic device

A technology of liposome vesicles and microfluidic devices, applied in liposome delivery, chemical instruments and methods, medical preparations of non-active ingredients, etc., can solve problems such as liposome inhomogeneity, and achieve repeatable production Good performance, improved utilization rate, and simple post-treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

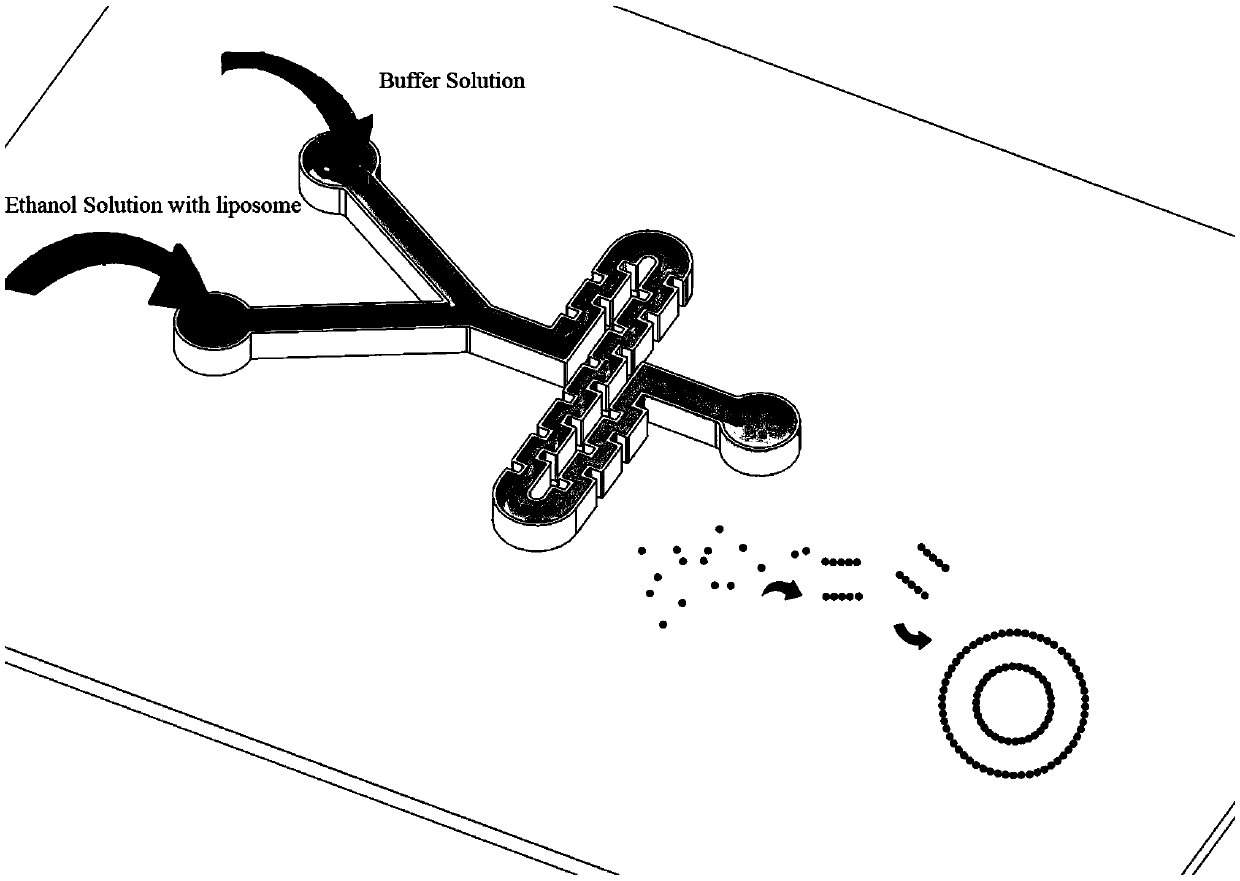

[0023] In this embodiment, see Figure 1 ~ Figure 4 , A controllable preparation method of liposome vesicles based on a microfluidic device, which adopts the principle of self-assembly preparation induced by interface reaction, and the steps are as follows:

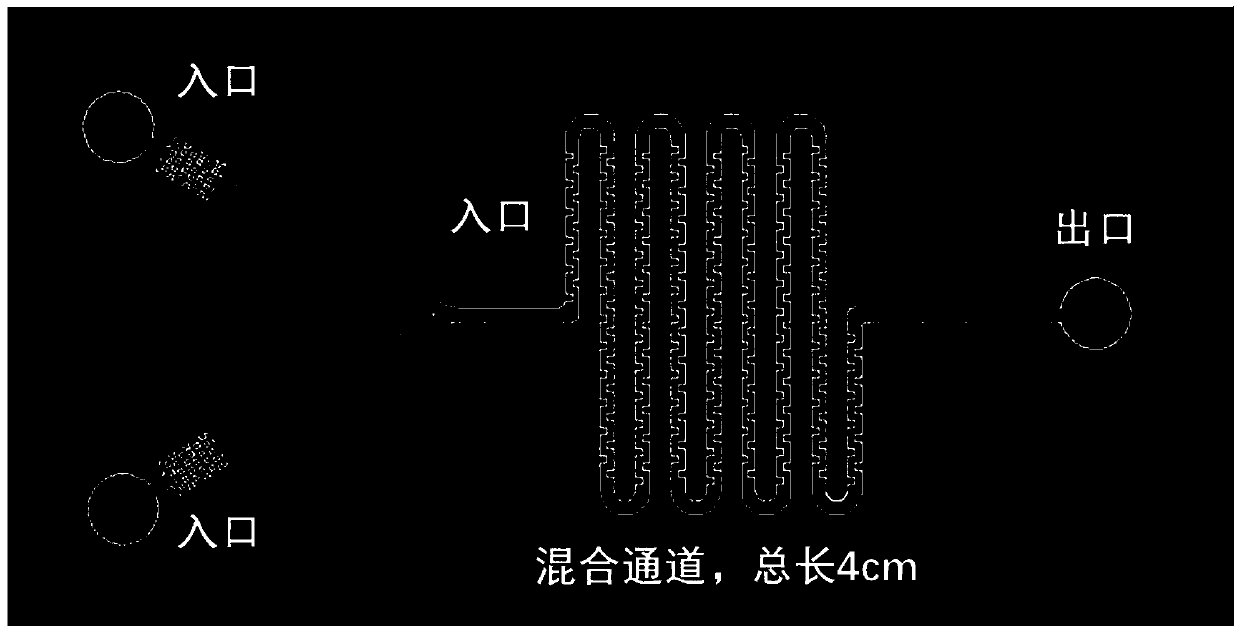

[0024] a. Using a microfluidic device, the microfluidic device is a "Y"-shaped microfluidic chip with a serpentine mixing channel, containing two injection ports and one outlet, forming a main channel connected by two branch channels. "Y" microchannel structure, two branch channels form two precursor solution injection ports, the end of the main channel forms a product outlet, the total length of the serpentine mixing channel is 4cm; the main microchannel of the "Y" microfluidic chip The channel is a serpentine mixed channel connected in sequence with four "S"-shaped structures; the four "S"-shaped structures of the main microchannel of the "Y"-shaped microfluidic chip in this embodiment are four "bow"-shaped structures in s...

Embodiment 2

[0043] This embodiment is basically the same as the first embodiment, and the special features are:

[0044] In this embodiment, a method for the controllable preparation of liposome vesicles based on a microfluidic device adopts the self-assembly preparation principle initiated by an interface reaction, and the steps are as follows:

[0045] a. This step is the same as the first embodiment;

[0046] b. This step is the same as the first embodiment;

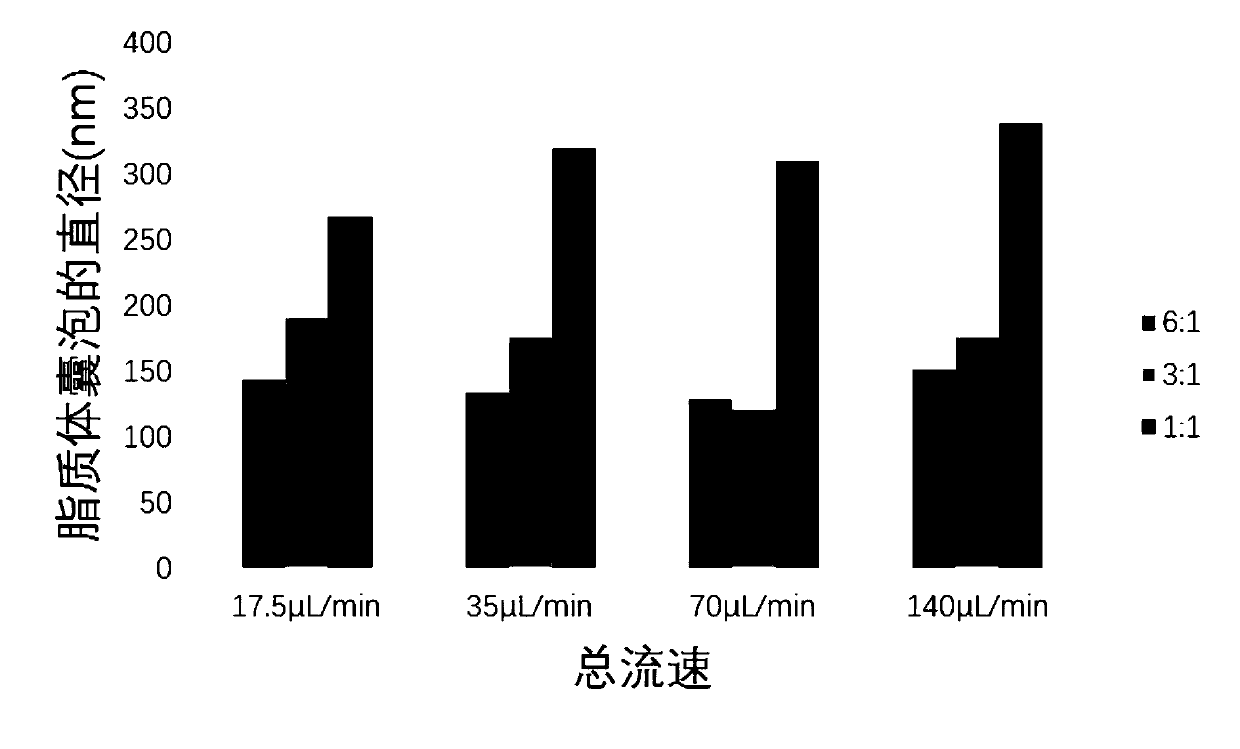

[0047] c. Use a constant pressure injection pump to inject the components of the precursor solution in step b into the branch microchannels of the "Y"-shaped microfluidic chip in step a through different injection ports, and set The total flow rate of the precursor solution, adjust the flow rate ratio of the hydroxyethylpiperazine ethanesulfonic acid buffer and the phospholipid molecular alcohol solution, and collect the product at the outlet of the main microchannel of the "Y"-shaped microfluidic chip. The product is the prepared produc...

Embodiment 3

[0052] This embodiment is basically the same as the previous embodiment, and the special features are:

[0053] In this embodiment, a method for the controllable preparation of liposome vesicles based on a microfluidic device adopts the self-assembly preparation principle initiated by an interface reaction, and the steps are as follows:

[0054] a. This step is the same as the first embodiment;

[0055] b. This step is the same as the first embodiment;

[0056] c. Use a constant pressure injection pump to inject the components of the precursor solution in step b into the branch microchannels of the "Y"-shaped microfluidic chip in step a through different injection ports, and set The total flow rate of the precursor solution, adjust the flow rate ratio of the hydroxyethylpiperazine ethanesulfonic acid buffer and the phospholipid molecular alcohol solution, and collect the product at the outlet of the main microchannel of the "Y"-shaped microfluidic chip. The product is the prepared pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com