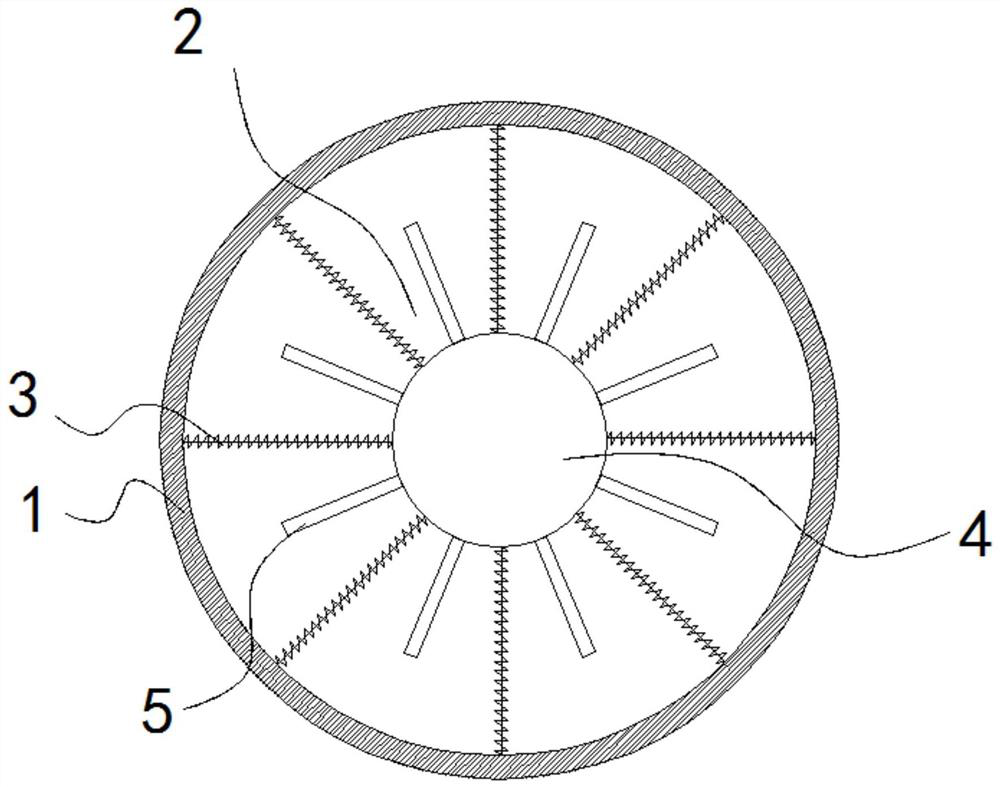

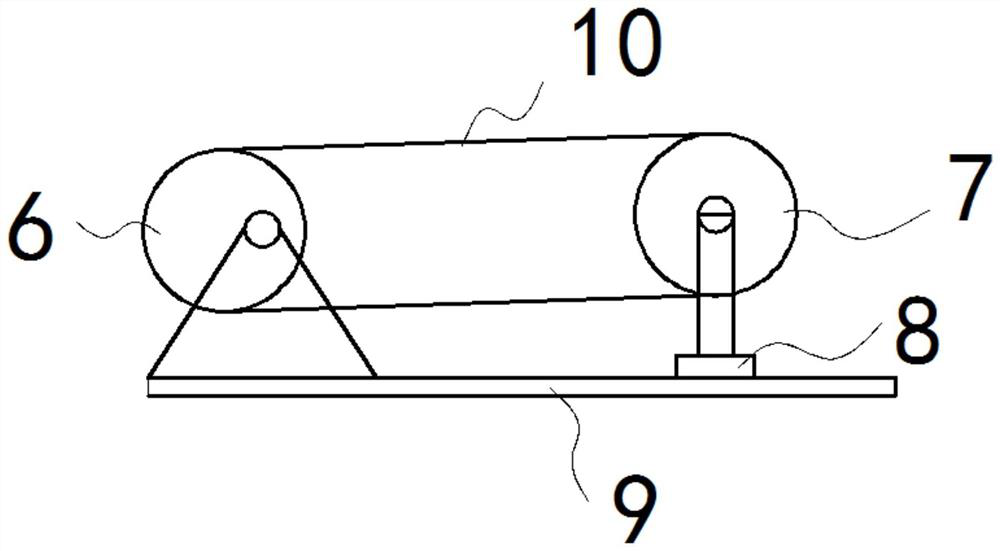

Large Drum Manufacturing Method

A manufacturing method and a large-scale technology, applied in the field of musical instruments, can solve the problems of poor drum cavity reverberation, easy leakage of sound, and influence on resonance, etc., and achieve the effect of dull drum body, good echo effect, and high resonance intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]A method for manufacturing a large drum, which includes the following steps:

[0040]Step 1. Soak the peach and red cones in lime water for 1-2 days, then take out to dry; soak the dried peach and red cones in water for 5 months, then take out and dry; The dried peach wood and red cones are fired, so that a carbonized layer of 1 cm is formed on the surface of the wood, and the carbonized layer is removed to obtain the core material; the core material is cut into pieces, then soaked in resin for 15 days and dried to obtain dried peach wood and To dry red vertebral wood, cut dry peach wood to 1.5 meters long, 8 cm wide, and 5 cm thick peach planks, and cut dry red vertebral wood to 1.5 meters long, 8 cm wide and 3 cm thick.

[0041]Step 2: Mix silica particles with a particle size of 50 microns and wood wax oil in a mass ratio of 1:10 to obtain an immersion liquid, and place the peach wood and red lamina in the immersion liquid for 30 days. Take out the natural air-dry, use the peach ...

Embodiment 2

[0052]A method for manufacturing a large drum, which includes the following steps:

[0053]Step 1. Soak the peach and red cones in lime water for 2 days, then take out to dry; soak the dried peach and red cones in water for 6 months, then take out and dry; then dry them The peach wood and red cones are fired to form a 2 cm carbonized layer on the surface of the wood. After removing the carbonized layer, the core material is obtained; the core material is cut into pieces, then soaked in epoxy resin for 20 days and dried to obtain dry peach wood and The thickness of the peach plank is 5 cm, the width is 8 cm; the thickness of the red vertebrae is 3 cm, the width is 8 cm, and the length is 1.2 meters.

[0054]Step 2: Mix silica particles with a particle size of 0 microns and wood wax oil in a mass ratio of 1:10 to obtain an immersion liquid, and place the peach wood and red lamina in the immersion liquid for 30 days. Take out the natural air-dried, peach plank as the main plate and red verte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com