Abrasion-resistant daily ceramic product and preparation method thereof

A technology for ceramic products and daily use, which is applied in the field of wear-resistant daily-use ceramic products and their preparation, which can solve the problems of poor wear resistance and low hardness, and achieve the effects of enhanced wear resistance, low cost, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

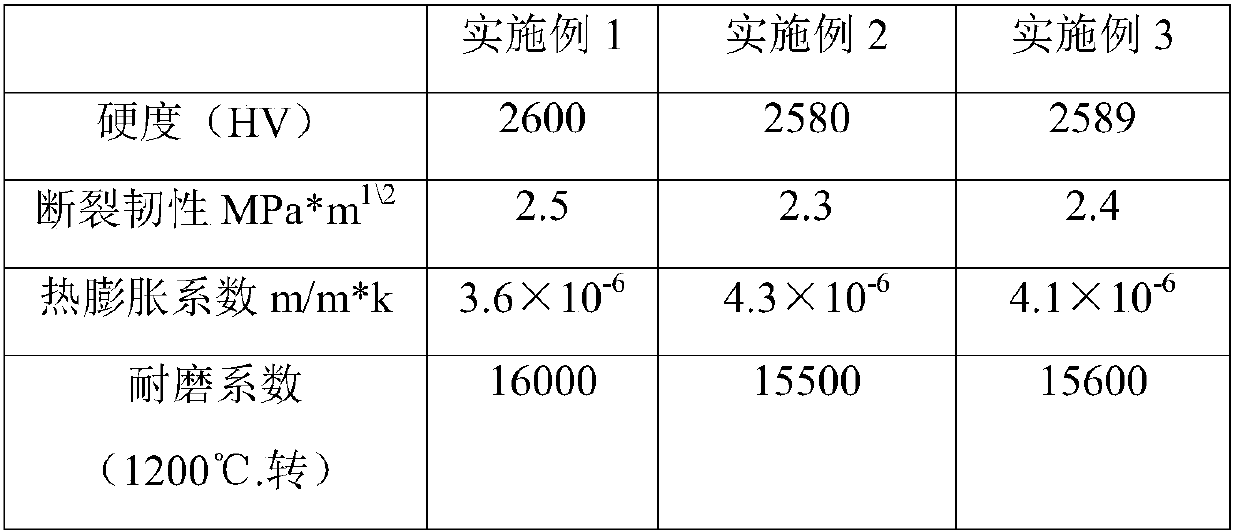

Examples

Embodiment 1

[0013] Embodiment 1: A wear-resistant daily-use ceramic product, the ceramic product contains the following raw materials in parts by weight: 35 parts of kaolin, 20 parts of albite, 15 parts of vermiculite, 10 parts of hollow microspheres, 10 parts of black mud, water-based 7 parts of acrylic emulsion, 8 parts of talcum powder, 8 parts of bamboo carbon fiber, 3 parts of sodium zirconate, 4 parts of rice husk powder, 15 parts of epoxy resin, 2 parts of polyester resin and 1.5 parts of dispersant.

[0014] A preparation method of wear-resistant daily-use ceramic products, comprising the steps of:

[0015] 1) Pulverize kaolin, albite, vermiculite, and hollow microspheres, and pass through an 80-mesh sieve to obtain material 1;

[0016] 2) Mix the material 1 obtained in step 1) with black mud, water-based acrylic emulsion, talcum powder, bamboo carbon fiber, sodium zirconate, and rice husk powder evenly, add to a ball mill and grind for 1 hour, then add epoxy resin and polyester r...

Embodiment 2

[0019] Embodiment 2: A wear-resistant daily ceramic product, the ceramic product contains the following raw materials in parts by weight: 30 parts of kaolin, 15 parts of albite, 10 parts of vermiculite, 5 parts of hollow microspheres, 5 parts of black mud, water-based 5 parts of acrylic emulsion, 6 parts of talcum powder, 5 parts of bamboo carbon fiber, 2 parts of sodium zirconate, 3 parts of rice hull powder, 10 parts of epoxy resin, 1 part of polyester resin and 1 part of dispersant.

[0020] A preparation method of wear-resistant daily-use ceramic products, comprising the steps of:

[0021] 1) Pulverize kaolin, albite, vermiculite, and hollow microspheres, and pass through an 80-mesh sieve to obtain material 1;

[0022] 2) Mix the material 1 obtained in step 1) with black mud, water-based acrylic emulsion, talcum powder, bamboo carbon fiber, sodium zirconate, and rice husk powder evenly, add to a ball mill and grind for 1 hour, then add epoxy resin and polyester resin to gr...

Embodiment 3

[0025] Embodiment 3: A wear-resistant daily-use ceramic product, the ceramic product contains the following raw materials in parts by weight: 40 parts of kaolin, 25 parts of albite, 20 parts of vermiculite, 15 parts of hollow microspheres, 14 parts of black mud, water-based 10 parts of acrylic emulsion, 10 parts of talcum powder, 10 parts of bamboo carbon fiber, 4 parts of sodium zirconate, 5 parts of rice husk powder, 20 parts of epoxy resin, 4 parts of polyester resin and 2 parts of dispersant.

[0026] A preparation method of wear-resistant daily-use ceramic products, comprising the steps of:

[0027] 1) Pulverize kaolin, albite, vermiculite, and hollow microspheres, and pass through a 100-mesh sieve to obtain material 1;

[0028] 2) Mix the material 1 obtained in step 1) with black mud, water-based acrylic emulsion, talcum powder, bamboo carbon fiber, sodium zirconate, and rice husk powder evenly, add to a ball mill and grind for 1 hour, then add epoxy resin and polyester ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com