Preparation method of high-strength ion exchange pre-stressed albite porcelain and porcelain product thereof

An ion exchange and ceramic product technology, which is applied to the preparation method of reinforced prestressed albite porcelain and the field of ceramic products, can solve the problem that it is difficult to popularize and apply advanced daily-use fine porcelain, and it is difficult to meet the use requirements of daily-use ceramic materials, etc. problems, to achieve high practical value and application prospects, preparation methods and application production are simple and easy to control, and the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

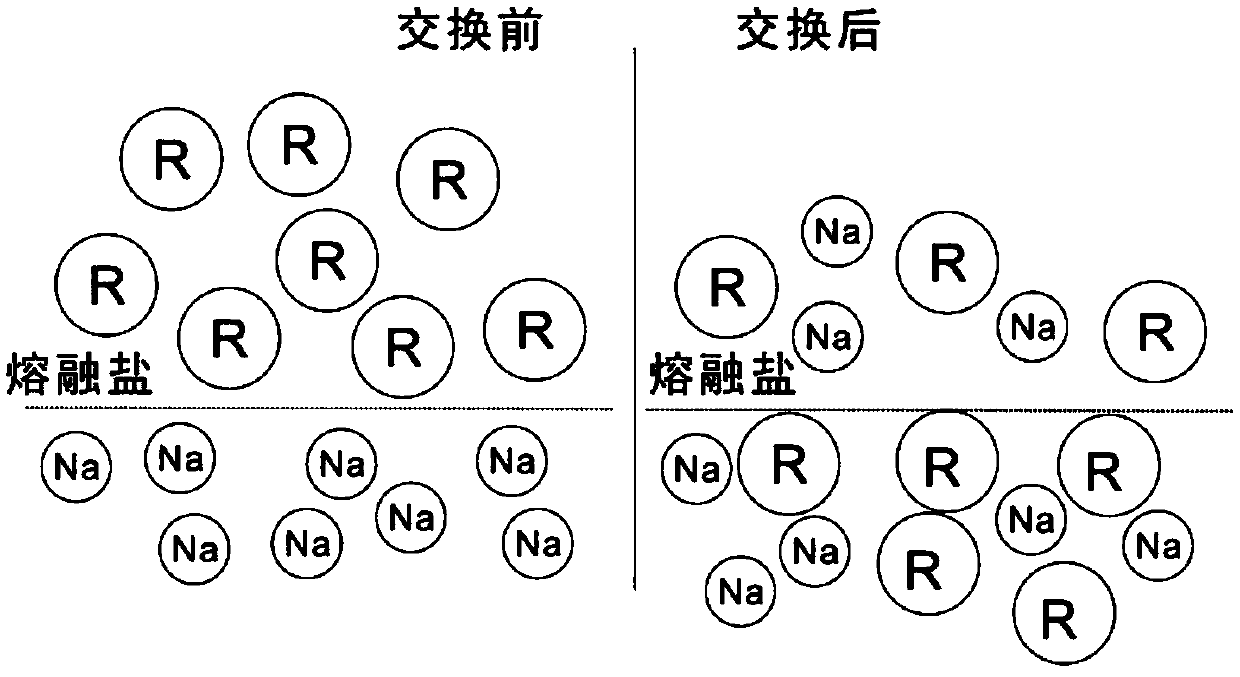

Method used

Image

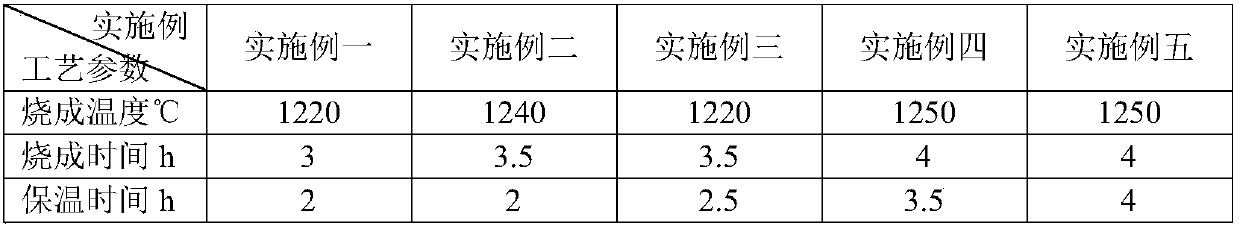

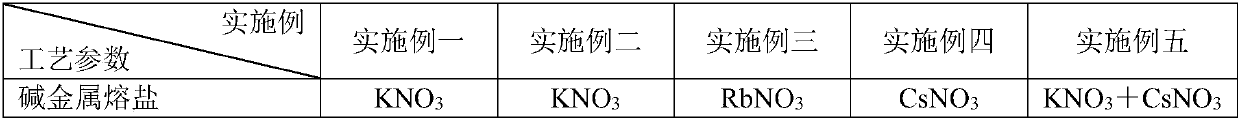

Examples

Embodiment Construction

[0021] 1. The albite porcelain body of the embodiment of the present invention is composed of its raw materials in parts by weight: porcelain stone 30 (containing 60wt% of quartz and 40wt% of albite), 5 of quartz, 50 of kaolin, and 15 of feldspar. Its chemical composition is: SiO 2 70wt%, Al 2 o 3 20wt%, Fe 2 o 3 0.1wt%, (MgO+CaO)1.7wt%, Na 2 O 2wt%, K 2 O 0.4wt%, I.L5.8wt%.

[0022] 2. The preparation method of the albite porcelain body of the embodiment of the present invention is:

[0023] Mix the raw materials according to the above formula, crush the sample, wet ball mill, sieve to remove iron, dry at 90°C, add 6% water to granulate, and pass through a 60-mesh sieve to obtain powder; then the powder The material is a metal film compact, the molding pressure is 20Mpa, the pressure is kept for 30s, and the albite porcelain body sample with a length of 40mm×width 10mm×thickness 5mm is obtained by pressing on one side.

[0024] 3. The preparation method of the high-st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com