Preparation technology of 2,2-methylbutanoic acid

A technology of dimethylbutyric acid and preparation process, which is applied in the field of preparation technology of 2,2-dimethylbutyric acid, can solve the problems of low yield of 2,2-dimethylbutyric acid and the like, and achieve market competitiveness Excellent, meet the market demand, the preparation process is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

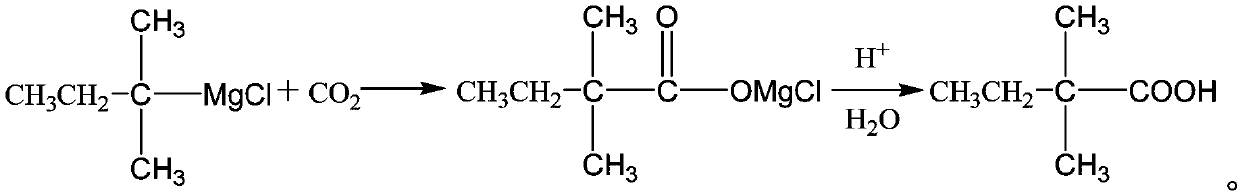

[0045] A kind of preparation technology of 2,2-dimethylbutanoic acid, it comprises:

[0046] (1) use Mechanism for the preparation of tert-amylmagnesium chloride Grignard reagent.

[0047] Specifically, add 27g of magnesium chips into the dry first reaction vessel, start stirring and heating, stop heating when heated to 50°C, and when the temperature in the reaction vessel reaches 60-70°C, add 2g of tetrahydrofuran and 2g of t The mixture of amyl chloride is used as the initiator to initiate the reaction. If a large amount of white smoke is produced in the reaction vessel and the temperature rises rapidly, it means that the reaction has been initiated. When the process of temperature rise becomes slow and tends to stop, keep dropping the mixed solution composed of 104.5g tert-amyl chloride, 100g tetrahydrofuran and 60g toluene at 80-90°C, and add the mixed solution at 80 Incubate at -90°C for 2 hours to obtain tert-amylmagnesium chloride Grignard reagent.

[0048] Wherein,...

Embodiment 2

[0056] A kind of preparation technology of 2,2-dimethylbutanoic acid, it comprises:

[0057] (1) Add 28g of magnesium chips into the dry first reaction vessel, start stirring and heating, stop heating when heated to 50°C, and when the temperature in the reaction vessel reaches 60-70°C, add 2g of tetrahydrofuran and 2g of tertiary The mixture of amyl chloride is used as the initiator to initiate the reaction. If a large amount of white smoke is produced in the reaction vessel and the temperature rises rapidly, it means that the reaction has been initiated. When the process of temperature rise becomes slow and tends to stop, keep dropping the mixed solution consisting of 104.5g tert-amyl chloride and 150g tetrahydrofuran at 80-90°C, and keep the mixture at 80-90°C Incubate for 2h to obtain tert-amylmagnesium chloride Grignard reagent.

[0058] Wherein, tert-amyl chloride is prepared by the method provided in the specification of this application.

[0059] (2) Cool the tert-amy...

Embodiment 3

[0064] A kind of preparation technology of 2,2-dimethylbutanoic acid, it comprises:

[0065] (1) Keep the temperature of 107g of tert-amylmagnesium chloride Grignard reagent in the temperature range of 35-45 DEG C and feed 90g of carbon dioxide, and keep it warm for 1h, so that the tert-amylmagnesium chloride Grignard reagent is fully added to carbon dioxide to obtain 2,2-Dimethylbutyrate reagent.

[0066] (2) Stir and mix 160g hydrochloric acid and 310g water, cool down to room temperature, dropwise add the 2,2-dimethylbutyrate reagent obtained in step (1), after the dropwise addition is completed, heat up and reflux for 4h, cool to room temperature, and obtain the fraction layer of the first reagent. Remove the water layer of the first reagent, add 500ml of water and 60g of caustic soda to the oil layer of the first reagent, stir for 30min, and continue to separate layers to obtain the second reagent. At this time, the 2,2-dimethylbutyric acid obtained by hydrolysis has It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com