Method for preparing metal nanostructures by self-absorbing nanoimprinting

A metal nanostructure and nanoimprint technology, applied in nanotechnology, metal material coating process, vacuum evaporation plating, etc., can solve the problem of inability to complete the evaporation gold stripping process, rough etching of gold sidewalls, and increase template loss, etc. problem, to achieve the effect of low cost, low cost and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions and advantages of the present disclosure clearer, the present disclosure will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

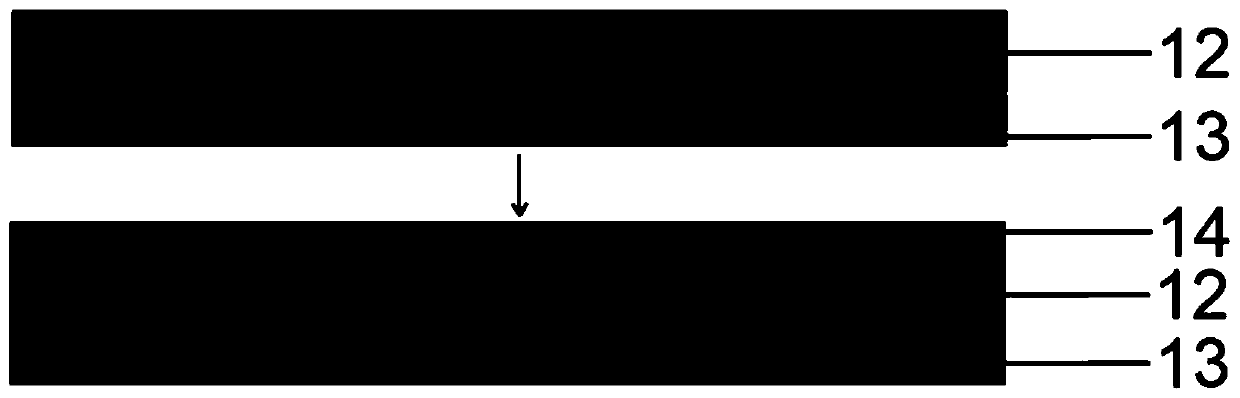

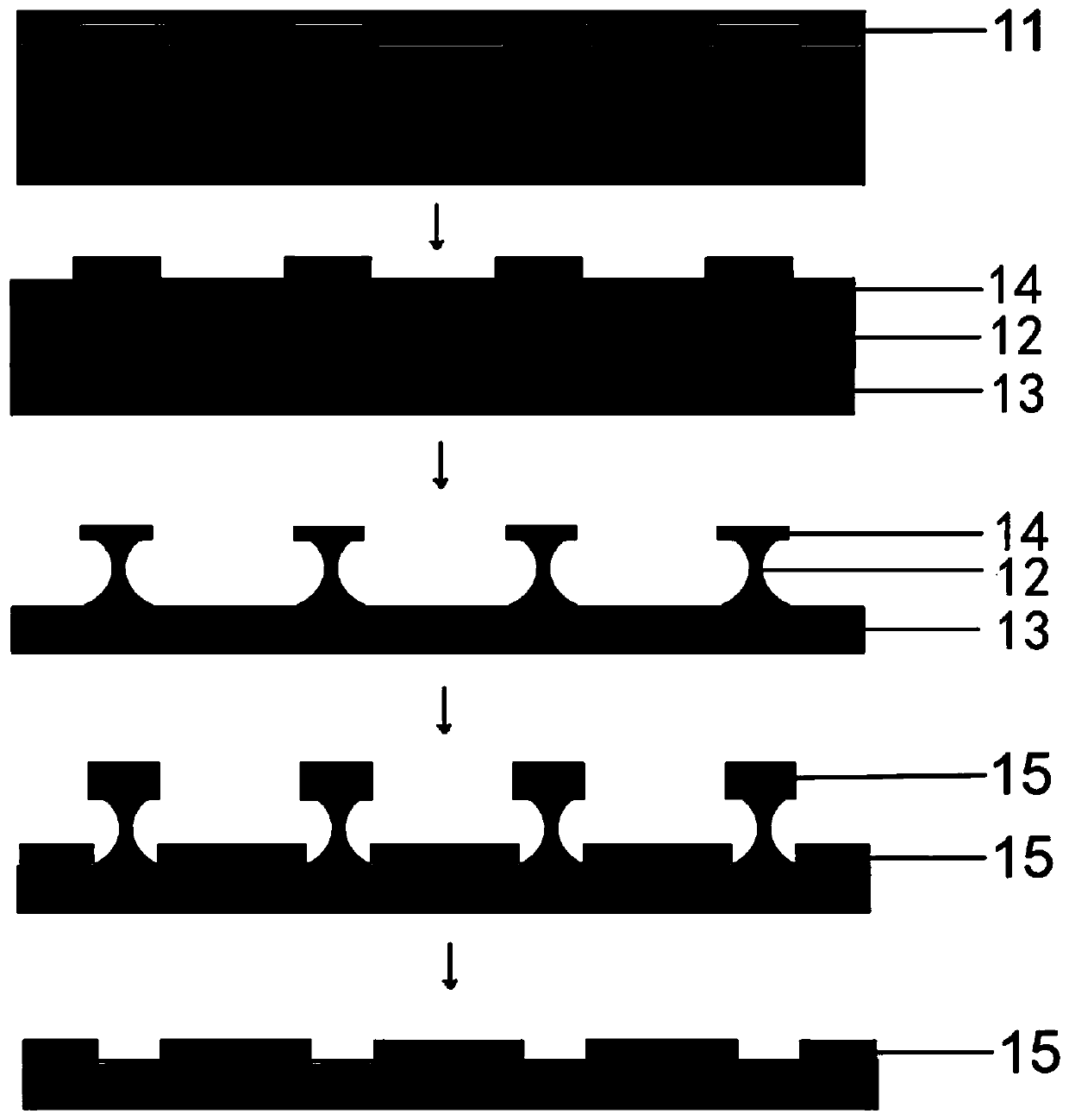

[0036] The present disclosure provides a large-area, low-cost self-absorption nanoimprinting method for preparing metal nanostructures, such as Figure 1-3 As shown, the method for preparing metal nanostructures by self-absorption nanoimprinting includes:

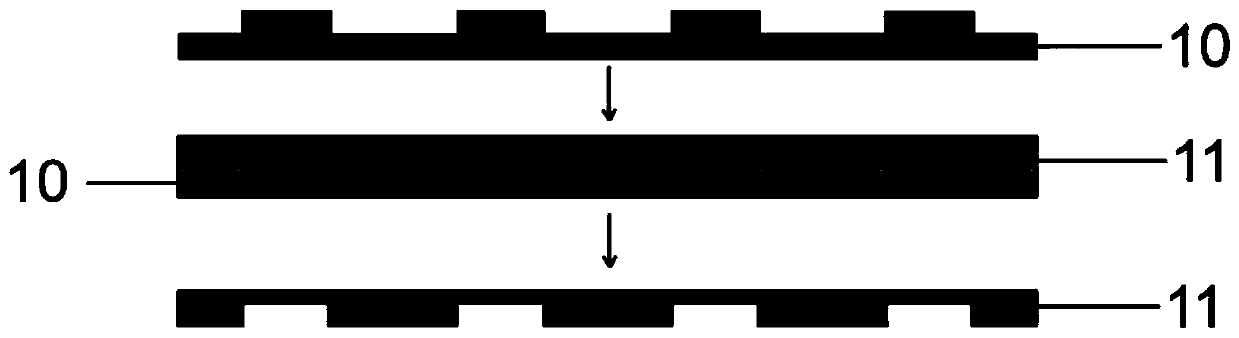

[0037] Step 1. Preparation of soft imprint template, such as figure 1 Shown:

[0038] Use the hard matrix nanoimprint template 10 to turn the mold to obtain the PDMS soft imprint template 11 (referred to as PDMS soft template), such as figure 1 As shown, the hard matrix nanoimprint template has nanostructures. Correspondingly, the PDMS soft imprint template obtained by remoulding also has nanostructures, and the two structures are opposite; using PDMS to remould the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com