Formed foil, preparation method and application thereof

A technology of forming foil and three-stage forming, which is applied in the field of aluminum foil manufacturing to achieve the effect of reducing corrosion ability, promoting defect exposure and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

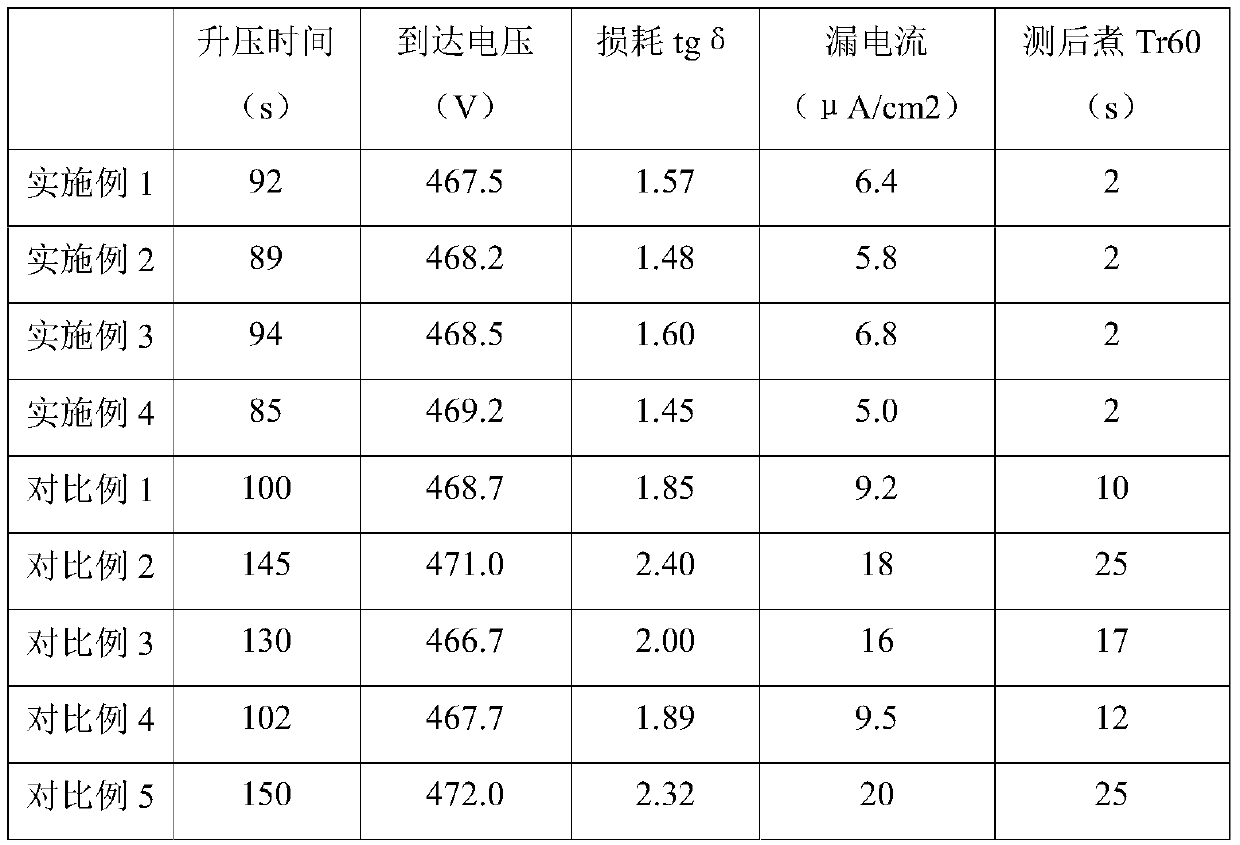

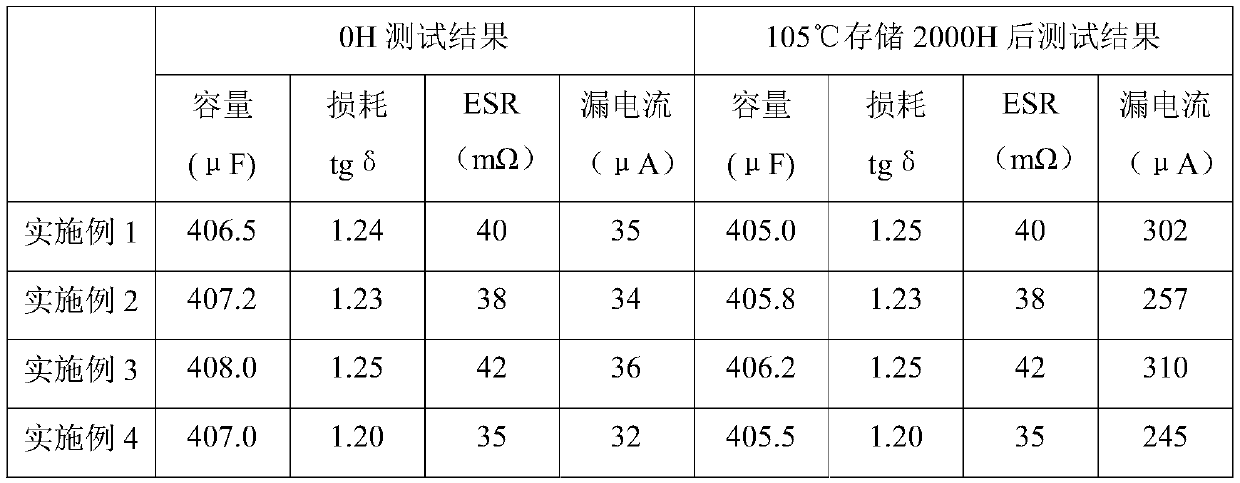

Examples

Embodiment 1

[0026] (1) Pretreatment: After cleaning the conventional medium and high pressure corroded foil, place it in a mixed solution of oxalic acid + boric acid for constant current oxidation treatment, wherein the concentration of oxalic acid in the solution is 1%, the concentration of boric acid is 0.5%, and the solution temperature is 35°C , current density 60mA / cm 2 , processing time 10min.

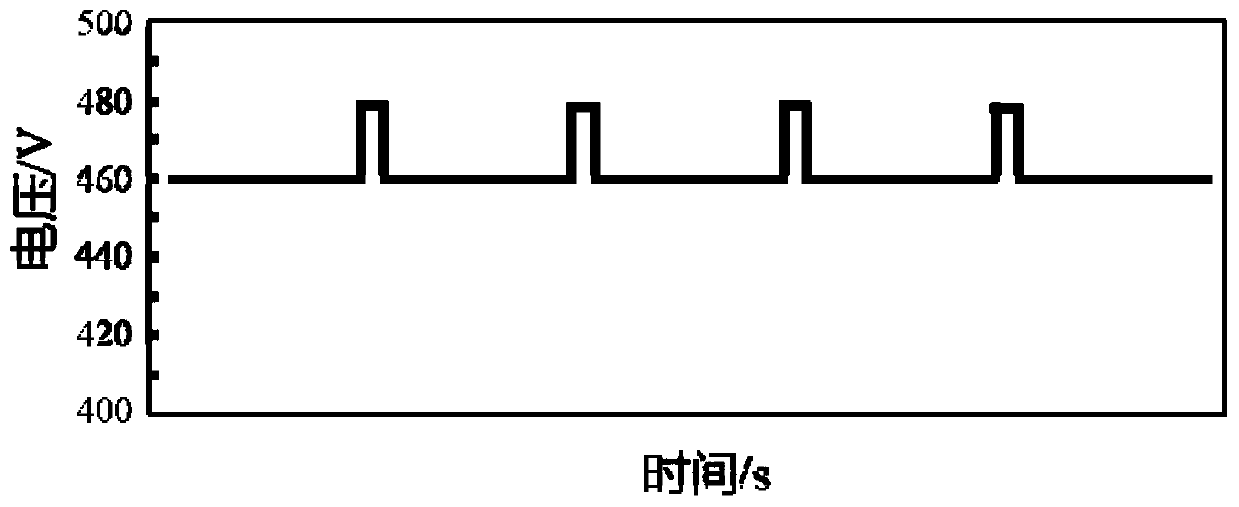

[0027] (2) Three-stage formation: After the electrode foil is washed with pure water, the electrode foil is placed in a solution of boric acid + boron ammonium for three-stage step-by-step voltage formation to a voltage of 460V, wherein the temperature of the bath solution is controlled at 45°C .

[0028] (3) The first high-temperature heat treatment: the formed foil was treated at a temperature of 300° C. for 4 minutes.

[0029] (4) First supplementary formation: After heat treatment, the formed foil is placed in a solution of boric acid + boron ammonium, and a 460V constant voltage prima...

Embodiment 2

[0037] (1) After cleaning the routinely used medium and high pressure corrosion foil, place it in a mixed solution of oxalic acid + boric acid for constant current oxidation treatment. The concentration of oxalic acid in the solution is 3%, the concentration of boric acid is 1%, the solution temperature is 35°C, and the current density is 30mA / cm 2 , processing time 15min.

[0038] (2) After the electrode foil is washed with pure water, the electrode foil is placed in a solution of boric acid + ammonium borate for 3-stage step-by-step voltage conversion to a voltage of 460V; the temperature of the bath solution is controlled at 45°C.

[0039] (3) The formed foil is placed at a temperature of 350° C. for 2 minutes.

[0040] (4) After heat treatment, the formed foil is placed in a solution of boric acid + boron ammonium, and a 460V constant voltage primary supplementary forming treatment is performed at 85°C.

[0041] (5) Put the chemically formed foil in a 3% phosphoric acid ...

Embodiment 3

[0048] (1) After cleaning the routinely used medium and high pressure corrosion foil, place it in a mixed solution of oxalic acid + boric acid for constant current oxidation treatment. The concentration of oxalic acid in the solution is 5%, the concentration of boric acid is 2%, the solution temperature is 15°C, and the current density is 10mA / cm 2 , processing time 30min.

[0049] (2) After the electrode foil is washed with pure water, the electrode foil is placed in a solution of boric acid + ammonium borate for 3-stage step-by-step voltage conversion to a voltage of 460V, and the temperature of the bath solution is controlled at 45°C.

[0050] (3) The formed foil is placed at a temperature of 400° C. for 2 minutes.

[0051] (4) After heat treatment, the formed foil is placed in a solution of boric acid + boron ammonium, and a 460V constant voltage primary supplementary forming treatment is performed at 85°C.

[0052] (5) Put the chemically formed foil in a 5% phosphoric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com