A single-direction double-action high-frequency vibration hot-press vacuum sintering furnace

A vacuum sintering furnace, high-frequency vibration technology, applied in the direction of furnace, charge, muffle furnace, etc., can solve the problems of difficult control of vibration pressure of cam vibration sintering furnace, high frequency response requirements of servo valve, high cost of hardware equipment, etc. Achieve the effects of easy control of vibration pressure, large vibration amplitude and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

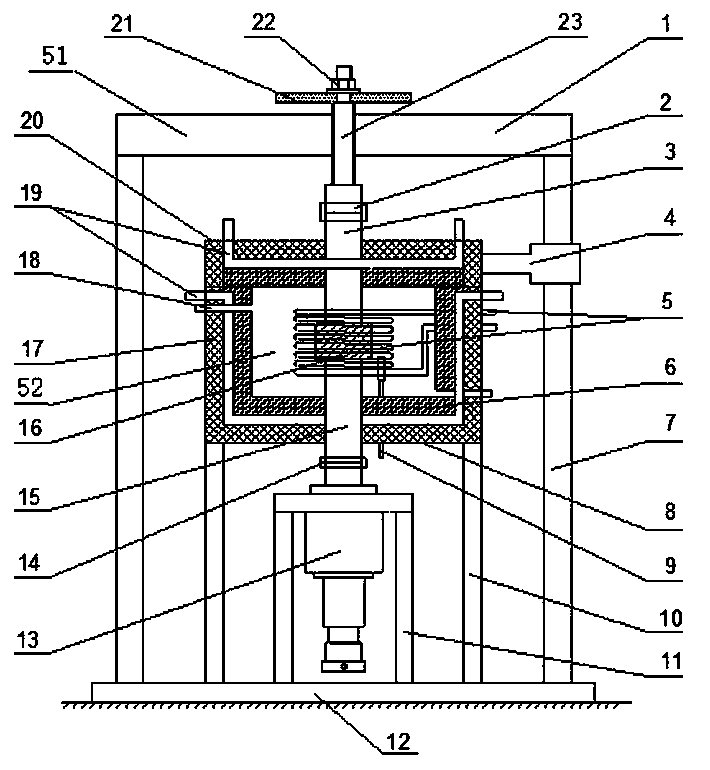

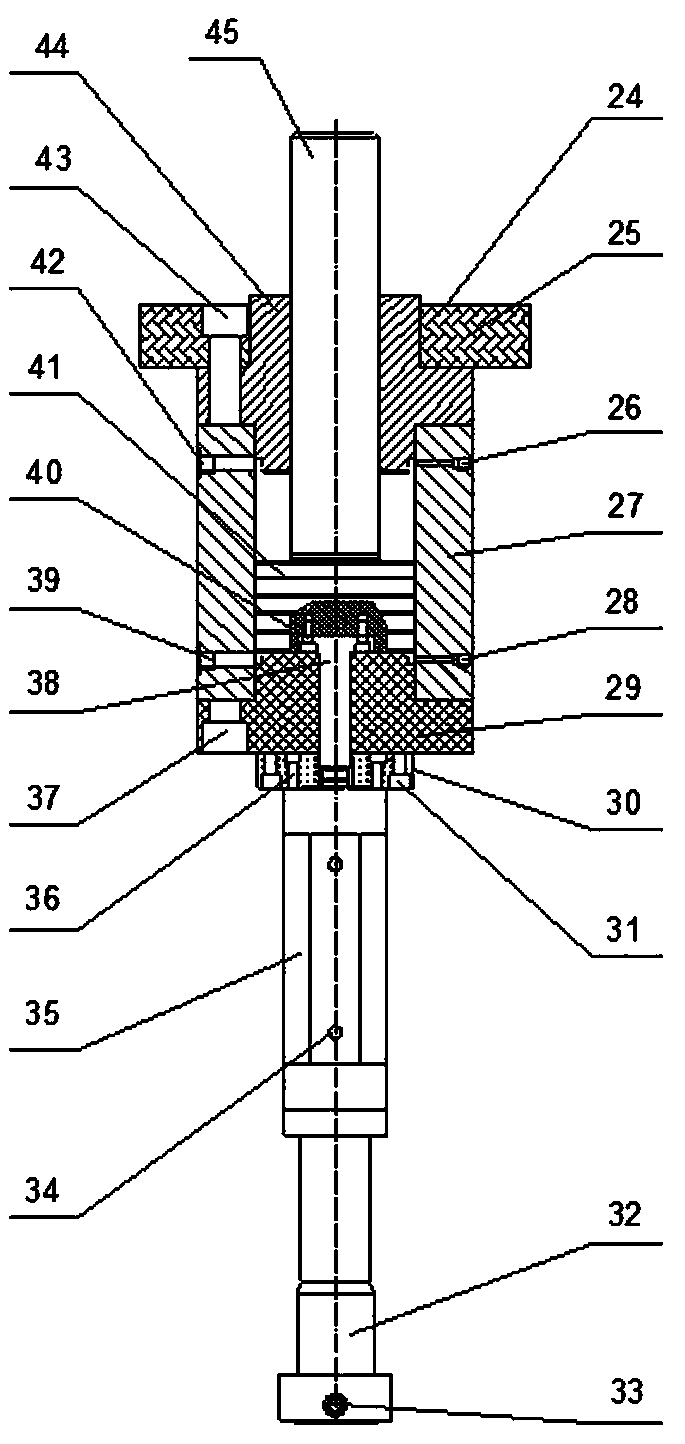

[0027] Attached below Figure 1-3 The present invention is described in further detail with specific embodiment:

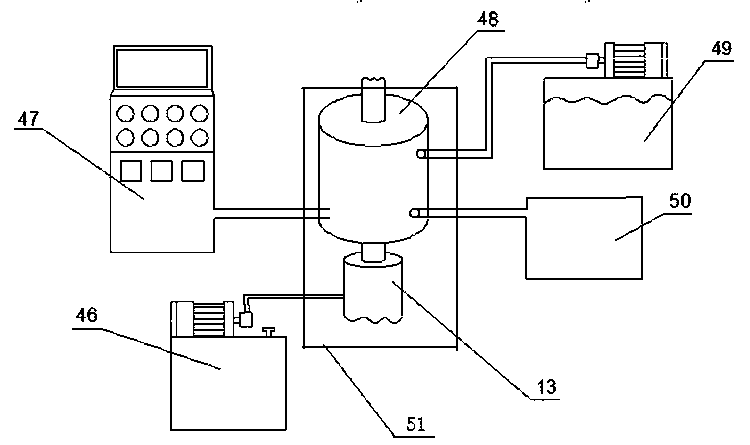

[0028] A single-direction double-action high-frequency vibration hot-press vacuum sintering furnace, including a control center 47, a hydraulic station 46, a cooling water station 49, a vacuum 50, a furnace body 48, a high-frequency vibration pressurization device 13, and a furnace frame 51, The furnace body 48 and the high-frequency vibration pressurizing device 13 are arranged inside the furnace frame 51 , and the control center 47 , the cooling water station 49 , and the hydraulic station 46 of the vacuum pump 50 are respectively arranged outside the furnace frame 51 .

[0029] The grate 51 is composed of a beam 1, a beam pillar 7, and a base 12, and the beam pillar 7 is vertically welded between the base 12 and the beam 1;

[0030] The body of furnace 48 is composed of connecting flange 2, upper pressure head 3, hinged connecting rod 4, induction coil 5, insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com