Full-life-cycle municipal sewage treatment monitoring method

A whole life cycle, urban sewage technology, applied in the whole life cycle sewage treatment field, can solve the problems of the sewage treatment plant not running normally, the operation cost of urban sewage treatment increasing, not paying attention to the technology platform, etc., to achieve the realization of sewage treatment and monitoring. The effect of management, improving sewage treatment efficiency, and improving comprehensive analysis capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

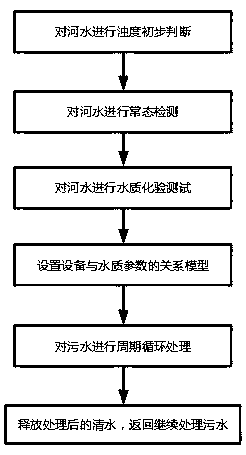

[0039] The present invention is realized through the following technical solutions, as figure 1 As shown, a whole life cycle urban sewage treatment monitoring method specifically includes the following steps:

[0040] Step F1: Open the gate of the water inlet pump house, let the river water flow into the catchment canal, and conduct a preliminary turbidity detection on the inflow river water;

[0041] Step F2: Carry out water quality testing and normal monitoring of the river water in the catchment channel, and display various parameters in the form of curves and reports;

[0042] Step F3: Design a set of relational models corresponding to the water quality parameters for the working of the Roots blower and self-priming pump in the catchment, and set the cycle working time, start the Roots blower and the self-priming pump to carry out the treatment of the river water in the catchment Treatment; water quality testing and normal monitoring again after each cycle;

[0043] Step...

Embodiment 2

[0048] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, the step F1 specifically includes the following steps:

[0049] Step F11: open the gate of the water inlet pump room, and introduce the water in the river into the catchment channel;

[0050] Step F12: The temperature sensor, flow sensor, liquid level sensor, and turbidity meter set in the water inlet pump room perform initialization detection on the river water, and the CPU controller connected to the temperature sensor, flow sensor, liquid level sensor, and turbidity meter passes through Ethernet sends the detection results to the partition data server;

[0051] Step F13: According to the initial water quality of the river water, the regional data server displays various parameters of the water quality in the form of curves and reports.

[0052] It should be noted that, through the above improvements, the water inlet pump room includes a sensor unit, an analog inpu...

Embodiment 3

[0057] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, the step F2 specifically includes the following steps:

[0058] Step F21: The regional data server extracts the river water in the water collection channel for normal detection, and the normal detection includes the pH value detection of the river water, COD analysis and detection, ammonia nitrogen analysis and detection, and total phosphorus analysis and detection;

[0059] Step F22: The partitioned data server conducts a water quality test on the river water. The water quality test includes the chemical oxygen demand COD, biochemical oxygen demand BOD, suspended solids SS, total phosphorus TP, total nitrogen TN, ammonia nitrogen NH3- N, nitrate nitrogen NO3-N, dissolved oxygen DO, sludge concentration MLSS, sludge sedimentation ratio SV30, sludge volume index SVI;

[0060] Step F23: The results of the normal detection and water quality testing are displayed in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com