Planar metal low-temperature heating device and fabrication process

A heating device and manufacturing process technology, applied in electric heating devices, ohmic resistance heating, heating element materials, etc., can solve the problems of short circuit of heating lines, poor toughness of ceramic sheets, fracture of ceramic sheets, etc., to increase support strength, high ease of processing, etc. Forming, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

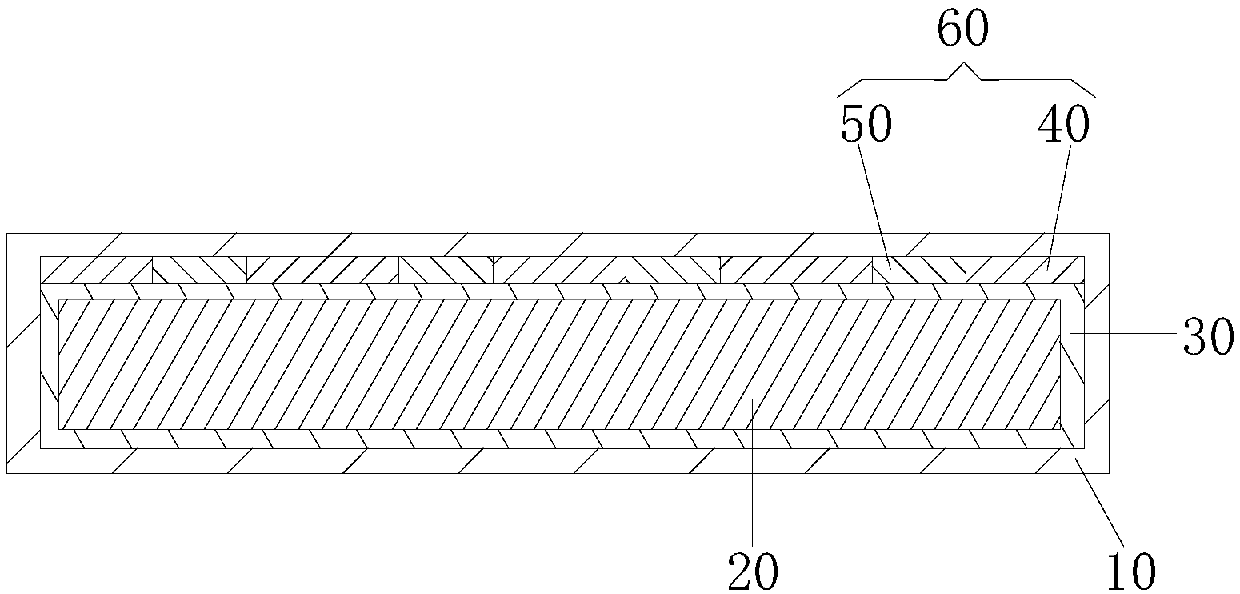

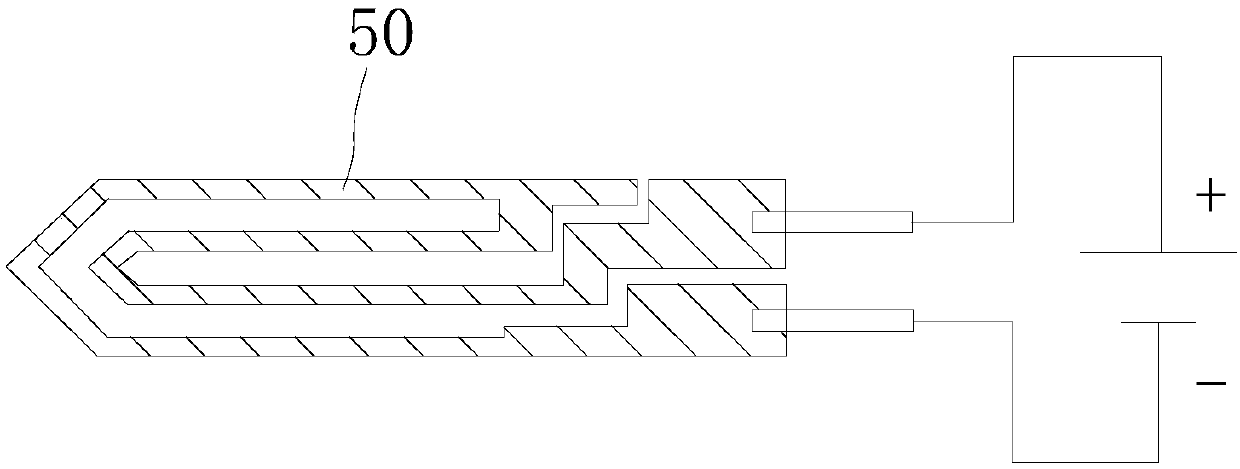

[0031] refer to figure 1 , figure 2 As shown, the present invention discloses a planar metal low-temperature heating device, specifically, the planar metal low-temperature heating device includes an outer protective glaze layer 10, a metal support sheet layer 20, an insulating medium layer 30, a support layer 40 and a metal heating track layer 50; the insulating medium layer 30 is coated on the outer surface of the metal support sheet layer 20, the metal heating trace layer 50 is embedded in the support layer 40, and the metal heating trace layer 50 and the support layer 40 form a filling Layer 60, the filling layer 60 is attached to the upper surface of the insulating medium layer 30; the outer protective glaze layer 10 wraps the filling layer 60 and the insulating medium layer 30; the metal heating trace layer The two ends of 50 protrude from the outer protective glaze layer 10, and the two ends of the metal heating track layer 50 are respectively connected to the positive...

Embodiment 2

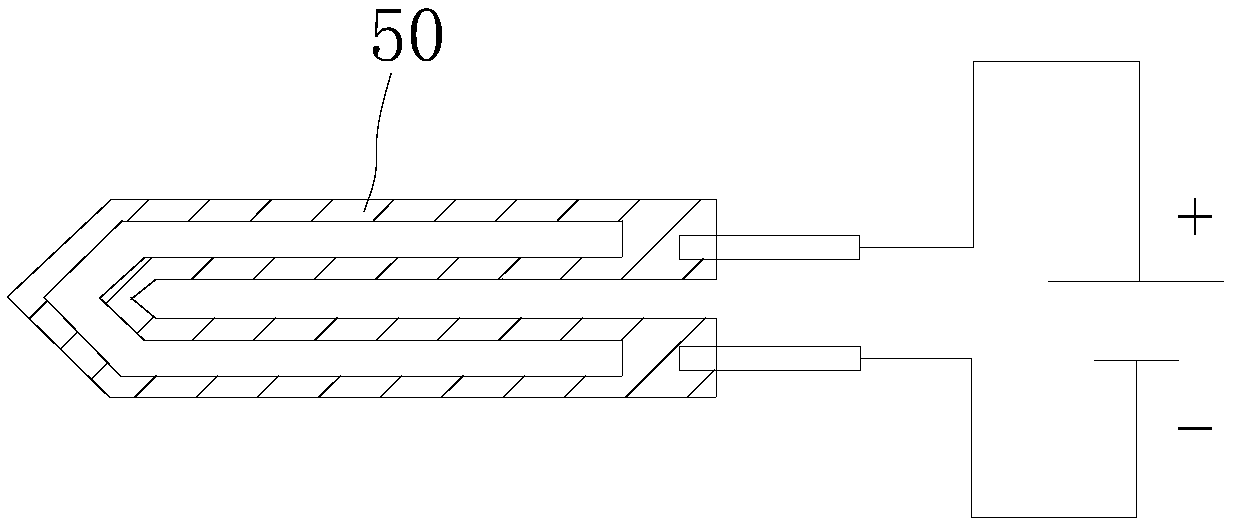

[0043] refer to figure 1 , image 3 As shown, this embodiment discloses a flat metal low-temperature heating device. In this embodiment, the structure of the flat metal low-temperature heating device is basically the same as that in Embodiment 1, and will not be described in detail in this embodiment. The difference in, such as image 3 As shown, the heating track of the metal heating track layer 50 is as follows image 3 As shown, the heating track is slightly different from that in Example 1.

[0044] In this embodiment, the present invention also discloses a manufacturing process of the above-mentioned planar metal low-temperature heating device. In this embodiment, the process includes the following steps:

[0045] A. Select any one of nickel-chromium alloy, iron-chromium-aluminum alloy, stainless steel, titanium and titanium alloy, and nickel-iron alloy as the base material of the metal heating track layer 50, and make the base material through stamping, etching, cutti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com